Abstract

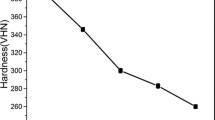

Test samples of martensite/ferrite duplex stainless steels (M/Fss) were prepared using thermal-mechanical processes and their slurry erosion behaviors were systematically studied. Test results show that hot rolling is an attractive process for improving erosion resistance. This improvement is more evident at higher impinging angles and larger reduction ratios. The thermal-mechanical-treated samples exhibit higher slurry erosion resistance for all impinging angles compared to that obtained by conventional quenching treatment without rolling. The variation tendency of the erosion rate versus the impinging angle for samples rolled with different degrees of reduction is similar in that the erosion rate initially increases and then decreases as the impinging angles increase from 15° to 90°, reaching a maximum at approximately 30°. After impingement erosion, the surface morphologies of the samples exhibit many long furrows and ridges at a low impinging angle of 30°. At a high impinging angle of 90°, the samples exhibit a worn surface with abundant overlapping and irregular concavities. The surface hardness of the samples after impingement erosion increases as the impinging angles and reduction ratios increase due to the enhanced effects of both work hardening and the formation of straininduced martensite.

Similar content being viewed by others

References

C. Petersen, and D. Rodrian, Int. J. Fatigue 30, 339 (2008).

A. F. Armas, C. Petersen, R. Schmitt, M. Avalos, and I. Alvarez, J. Nucl. Mater. 329–333, 252 (2004).

C. Petersen, J. Nucl. Mater. 500–504, 307 (2002).

A. F. Armas, M. Avalos, I. Alvarez-Armas, C. Petersen, and R. Schmitt, J. Nucl. Mater. 258–263, 1204 (1998).

J. G. Parr and A. Hanson, An Introduction to Stainless Steel, p. 32, ASM, Metals Park, OH (1986).

I. Finnie, Wear 3, 87 (1960).

J. G. A. Bitter, Wear 6, 5 (1963).

S. Jahanmir, Wear 61, 309 (1980).

J. M. Robinson, and M. P. Shaw, Int. Mater. Rev. 39, 113 (1994).

A. A. C. Recco, D. López, A. F. Bevilacqua, F. da Silva, and A. P. Tschiptschin, Surf. Coat. Technol. 202, 993 (2007).

J. F. Santa, J. C. Baena, and A. Toro, Wear 263, 258 (2007).

S. I. Shim, Y. S. Park, S. T. Kim, and C. B. Song, Met. Mater. Int. 8, 301 (2002).

G. T. Burstein and K. Sasaki, Wear 240, 80 (2000).

A. Toro, A. Sinatora, D. K. Tanaka, and A. P. Tschiptschin, Wear 251, 1257 (2001).

D. C. Wen, ISIJ Int. 46, 728 (2006).

K. W. Andrews, JISI 203, 721 (1965).

A. W. Ruff and L. K. Ives, Wear 35, 195 (1975).

F. B. Pickering, Physical Metallurgy and the Design of Steels, p. 258, Applied Science Publishers LTD, London (1978).

B. V. N. Rao and G. Thomas, Metall. Trans. A 11, 441 (1980).

S. Barnard, G. D. W. Smith, M. Sarikaya, and G. Thomas, Scripta met. 15, 387 (1981).

B. Miao, D. O. Northwood, L. C. Lim, and M. O. Lai, Mater. Sci. Eng. A 171, 21 (1993).

H. Y. Teng, C. H. Hsu, S. C. Chiu, and D. C. Wen, Mater. Trans. 44, 1480 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, DC. Improvement of slurry erosion resistance of martensite/ferrite duplex stainless steel by hot rolling. Met. Mater. Int. 16, 13–19 (2010). https://doi.org/10.1007/s12540-010-0013-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-010-0013-z