Abstract

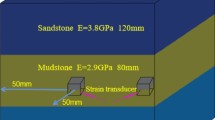

Multi-staged fracturing in the roof of an outburst coal seam has been applied to more and more coal mines for use in coalbed methane (CBM) pre-drainage in China. The multiple artificial fractures in the roof can traverse the coal–rock interface to communicate outburst coal seams and achieve gas drainage. However, whether a fracture network can form in the roof is closely related to the in-situ stress, mechanical properties of the coal and rock, fracturing pattern, interval distance, fluid flow, and other aspects. Additionally, the mechanism of multi-staged fracturing in CBM reservoirs is not very clear. In this paper, we theoretically studied the mechanical conditions of a forming fracture network in the roof of an outburst coal seam. The optimal interval distances of sequential fracturing and alternating fracturing were obtained based on the horizontal stress-difference coefficient. In addition, we numerically simulated the effects of the minimum horizontal stress and stress ratio on the fracture propagation and fracture network using RFPA2D-Flow software. The research results indicated that the induced stress difference increases at first and then decreases with the increasing of the interval distance. Turning phenomenon of the maximum stress in the local area near multiple fractures should meet the condition that the induced stress difference is bigger than the horizontal stress difference. The optimal interval distance of the forming fracture network depended on the position of the maximum induced stress difference, which was closely related to the fracture height, Poisson’s ratio, and horizontal stress difference, but was unrelated to the net pressure in the fracture. When the horizontal stress difference was constant, the initial pressure and fracture initiation time increased with the increasing of the minimum horizontal stress. The stress ratio of a single fracture was inversely proportional to the fracture width. In addition, the induced stress may make the two stresses become close, which is conducive to forming the fracture network. The research results can provide a theoretical basis and data support for studying the mechanism of the forming fracture network in the roof of an outburst coal seam.

Similar content being viewed by others

References

Chaohua G, Mingzhen W, Hong L (2018) Study of gas production from shale reservoirs with multi-stage hydraulic fracturing horizontal well considering multiple transport mechanisms. PLoS ONE 13(1):e0188480. https://doi.org/10.1371/journal.pone.0188480

Chen M, Zhang S, Xu Y, Ma X, Zou Y (2020) A numerical method for simulating planar 3D multi-fracture propagation in multi-stage fracturing of horizontal wells. Petrol Explor Dev 47(1):171–183. https://doi.org/10.1016/S1876-3804(20)60016-7

Chen S (n.d.) Based on the formation characteristics of shale gas horizontal well clumps and perforating parameters optimization. China University of Petroleum, Beijing

Dahim S, Taghavinejad A, Razghandi M, Rigi HR, Moeini K, Jamshidi S, Sharifi M (2020) Pressure and rate transient modeling of multi fractured horizontal wells in shale gas condensate reservoirs. J Pet Sci Eng 185:106566. https://doi.org/10.1016/j.petrol.2019.106566

De Silva VRS, Ranjith PG (2019) Intermittent and multi-stage fracture stimulation to optimise fracture propagation around a single injection well for enhanced in-situ leaching applications. Eng Fract Mech 220:106662. https://doi.org/10.1016/j.engfracmech.2019.106662

Feng Q, Jiang Z, Wang S, Zhang G, Qin Y, Xu S, Zhang W (2019) Optimization of reasonable production pressure drop of multi-stage fractured horizontal wells in tight oil reservoirs. J Pet Explor Prod Technol 9(3):1943–1951. https://doi.org/10.1007/s13202-018-0586-5

Gao D, Liu Y, Pan S, Wang J, Zhou X (2020) Longitudinal interference analysis of shale gas multi-stage fracturing horizontal wells upon high-precision pressure test. Energy Sci Eng 8(7):2387–2401. https://doi.org/10.1002/ese3.671

Jian Z, Yijin Z, Tingxue J, Baoping Z (2018) Laboratory scale research on the impact of stress shadow and natural fractures on fracture geometry during horizontal multi-staged fracturing in shale. Int J Rock Mech Min Sci 107:282–287. https://doi.org/10.1016/j.ijrmms.2018.03.007

Lecampion B, Desroches J (2015) Robustness to formation geological heterogeneities of the limited entry technique for multi-stage fracturing of horizontal wells. Rock Mech Rock Eng 48(6):2637–2644. https://doi.org/10.1007/s00603-015-0836-5

Li W, Li L, Tang C (2016) Numerical simulation research on mechanism of induced stress perturbation between parallel fractures in horizontal wells. Nat Gas Geosci 27(11):2043–2053

Liu Q, Chen Y, Wang W, Liu H, Hu X, Xie Y (2017) A productivity prediction model for multiple fractured horizontal wells in shale gas reservoirs. J Nat Gas Sci Eng 42:252–261. https://doi.org/10.1016/j.jngse.2017.03.004

Ma G, Su X, Lin H et al (2014) A theory and technical system of permeability enhancement to extract coal gas by fracture network stimulating in adjacent rocks and coal reservoirs. Nat Gas Ind 34(8):53–60. https://doi.org/10.3787/j.issn.1000-0976.2014.08.008

MoradiDowlatabad M, Jamiolahmady M (2018) The performance evaluation and design optimisation of multiple fractured horizontal wells in tight reservoirs. J Nat Gas Sci Eng 49:19–31. https://doi.org/10.1016/j.jngse.2017.10.011

Siddharnshetty P, Wu K, Kwon JS (2018) Optimization of simultaneously propagating multiple fractures in hydraulic fracturing to achieve uniform growth using data-based model reduction. Chem Eng Res Design 136:675–686. https://doi.org/10.1016/j.cherd.2018.06.015

Sneddon IN (1946) The distribution of stress in the neighborhood of a crack in an elastic solid. Proc R Soc Lond Ser A 187(1009):229–260

Tang H, Winterfeld PH, Wu Y, Huang Z, Pan Z, Zhang J (2016) Integrated simulation of multi-stage hydraulic fracturing in unconventional reservoirs. J Nat Gas Sci Eng 36:875–892. https://doi.org/10.1016/j.jngse.2016.11.018

Wasantha PLP, Konietzky H, Xu C (2019) Effect of in-situ stress contrast on fracture containment during single- and multi-stage hydraulic fracturing. Eng Fract Mech 205:175–189. https://doi.org/10.1016/j.engfracmech.2018.11.016

Xu Y, Li X, Liu Q (2020) Pressure performance of multi-stage fractured horizontal well with stimulated reservoir volume and irregular fractures distribution in shale gas reservoirs. J Nat Gas Sci Eng 77:103209. https://doi.org/10.1016/j.jngse.2020.103209

Xuyang G, Song Hongqing Wu, Kan KJ (2018) Pressure characteristics and performance of multi-stage fractured horizontal well in shale gas reservoirs with coupled flow and geomechanics. J Petrol Sci Eng 163:1–15. https://doi.org/10.1016/j.petrol.2017.12.038

Yu R, Bian Y, Qi Y, Zhang J, Zhang J, Zhang X, Gou W, Yan J, Wang M (2017) Qualitative modeling of multi-stage fractured horizontal well productivity in shale gas reservoir. Energy Explor Exploit 35(4):516–527. https://doi.org/10.1177/0144598716679960

Zeng J, Li W, Liu J, Leong Y-K, Elsworth D, Tian J, Guo J, Zeng F (2020) Analytical solutions for multi-stage fractured shale gas reservoirs with damaged fractures and stimulated reservoir volumes. J Nat Gas Sci Eng 187:106686. https://doi.org/10.1016/j.petrol.2019.106686

Zhao J, Chen X, Li Y, Fu B, Xu W (2017) Numerical simulation of multi-stage fracturing and optimization of perforation in a horizontal well. Pet Explor Dev 44(1):119–126. https://doi.org/10.1016/S1876-3804(17)30015-0

Zhou J, Li C, Deng R, Li Z, Yang P (2018) Method for fracture network calculation in multi-staged horizontal drilling in shale reservoirs. Chem Technol Fuels Oils 54(4):493–499. https://doi.org/10.1007/s10553-018-0951-6

Zongxiao R, Xiaodong W, Guoqing H, Lingyan L, Xiaojun W, Guanghui Z, Hun L, Jiaming Z, Xianwei Z (2017) Transient pressure behavior of multi-stage fractured horizontal wells in stress-sensitive tight oil reservoirs. J Petrol Sci Eng 157:1197–1208. https://doi.org/10.1016/j.petrol.2017.07.073

Acknowledgements

The authors deeply appreciate the financial supports provided by the Doctoral Program of Henan University of Engineering (DKJ2020005); Natural Science Foundation of Chongqing, China (cstc2019jcyj-msxmX0488); and Science and Technology Research Program of Chongqing Municipal Education Commission (KJQN201901338).

Author information

Authors and Affiliations

Contributions

Fan Zhang and Yang Tang analyzed the theoretical study. Fan Zhang performed the numerical simulation. Fan Zhang and Yang Tang analyzed the results of numerical simulation and prepared the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no conflicts of interest.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Zhang, F., Tang, Y. Mechanical analysis and numerical simulation of a forming fracture network in the roof of an outburst coal seam by multi-staged fracturing. Arab J Geosci 15, 349 (2022). https://doi.org/10.1007/s12517-022-09499-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-09499-0