Abstract

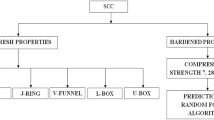

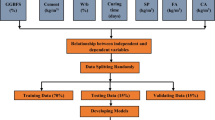

The present research article is focusing on the utilization of ground granulated blast furnace slag (GGBFS), ladle furnace slag (LFS) and sugarcane bagasse ash (SCBA) as the partial substitution of ordinary Portland cement (OPC) in concrete mix in order to create a sustainable environment and enhance the engineering performance. The primary purpose of the study is to predict the optimum percentage of different additives in varying proportions, i.e. individually and in a combined manner also to construct a sustainable rigid pavement. Therefore, accurate estimation of strength evaluation is required to minimize the effort. In the current investigation, different modeling analysis techniques have been attempted with different soft computing tools, namely random forest (RF), random tree (RT), M5P, reduced-error pruning (REP) tree and linear regression (LR) to estimate the compressive strength of the concrete using the experimental data. In the present study, all the mentioned additives were added in the concrete mix as the replacement of OPC up to 35%. On the basis of the findings, it was observed that 20% of all the additives in individual form might be used as the partial substitute of OPC. While, in a combined form, concrete mix having 5% GGBFS, 10% LFS and 15% of SCBA was showing the optimum strength value. However, it was also observed that the greater percentage of all the additives can be utilized with an increment in the curing time period. RF approach was found most permissible approach to predict the strength value for green concrete as it was exhibiting higher value of coefficient of correlation, low value of mean absolute error and the root mean square error as revealed by outcomes of the models and statistical assessments methods. Sensitivity analysis is carried out and found that the curing time in days is the utmost effective input variable for estimating the compressive strength of concrete using this data set.

Similar content being viewed by others

References

Ali MB, Saidur R, Hossain MS (2011) A review on emission analysis in cement industries. Renew Sustain Energy Rev 15(5):2252–2261. https://doi.org/10.1016/j.rser.2011.02.014

Amin N (2011) Use of bagasse ash in concrete and its impact on the strength and chloride resistivity. J Mater Civ Eng 23(5):717–720. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000227

Anupam AK, Kumar P, Ransinchung GD, Shah Yu (2017) Study on performance and efficacy of industrial waste materials in road construction: fly ash and bagasse ash. Airfield and Highway Pavements, DOI 10(1061/9780784480946):005

Barddal JP, Enembreck F, Gomes HM, Bifet A, Pfahringer B (2019) Merit-guided dynamic feature selection filter for data streams. Expert Syst Appl 116:227–242. https://doi.org/10.1016/j.eswa.2018.09.031

Behnood A, Golafshani EM (2020) Machine learning study of the mechanical properties of concretes containing waste foundry sand. Constr Build Mater 243:118152. https://doi.org/10.1016/j.conbuildmat.2020.118152

BIS (Bureau of Indian Standards). (1959). Methods of test for strength of concrete, IS: 516, BIS, New Delhi, India.

BIS (Bureau of Indian Standards). (1988a). Methods of physical tests for hydraulic cement. Determination of initial and final setting times, IS 4031 Part 5, New Delhi, India.

BIS (Bureau of Indian Standards) (1988) Methods of physical tests for hydraulic cement: Determination of density, IS 4031 Part 11. New Delhi, India

BIS (Bureau of Indian Standards). (1997). Methods of test for aggregates for concrete, IS: 2386, BIS, New Delhi, India.

BIS (Bureau of Indian Standards). (1999). Concrete Admixtures Specification, IS: 9103, BIS, New Delhi, India.

BIS (Bureau of Indian Standards). (2005). Methods of physical tests for hydraulic cement. Determination of consistency of standard cement paste, IS 4031 Part 4, New Delhi, India.

BIS (Bureau of Indian Standards). (2007) Specification for coarse and fine aggregates from natural sources for concrete, IS 383–07. New Delhi, India

BIS (Bureau of Indian Standards). (2019) Concrete Mix Proportioning – Guidelines, IS 10262. New Delhi, India

BIS (Bureau of Indian Standards). (1959). Method of tests for strength of Concrete, IS 516, Bureau of Indian Standards, New Delhi.

BIS (Bureau of Indian Standards) (1970) Specification for coarse and fine aggregates from natural sources for Concrete, IS 383, New Delhi.

Marinho BAL, Mol Santos CM, Carvalho, J.M.F.de., Mendes, J.C., Brigolini, G.J., & André Fiorotti Peixoto, R. (2017) Ladle furnace slag as binder for cement-based composites. J Mater Civ Eng 29(11):04017207. https://doi.org/10.1061/(asce)mt.1943-5533.0002061

Breiman L. (1996). Bagging predictors. Machine learning.24(2):123–40.

Breiman, L. (1999). Random forests. UC Berkeley TR567.

Breiman L (2001) Random forests. Mach Learn 45(1):5–32

Cutler A, Cutler DR, Stevens JR (2012) Random forests. Ensemble machine learning. Springer, Boston, MA, pp 157–175

Das S, Singh G, Ahmed AA, Saha S, Karmakar S (2015) Ground Granulated Blast Furnace Slag (GGBFS) based Concrete Exposed to Artificial Marine Environment (AME) and Sustainable Retrofitting using Glass Fiber Reinforced Polymer (GFRP) sheets. Procedia Soc Behav Sci 195:2804–2812. https://doi.org/10.1016/j.sbspro.2015.06.397

Deepika S, Anand G, Bahurudeen A, Santhanam M (2017) Construction products with sugarcane bagasse ash binder. J Mater Civ Eng 29(10):04017189. https://doi.org/10.1061/(asce)mt.1943-5533.0001999

Esmaeilbeiki, F., Nikpour, M. R., Singh, V. K., Kisi, O., Sihag, P., &Sanikhani, H. (2020). Exploring the application of soft computing techniques for spatial evaluation of groundwater quality variables. Journal of Cleaner Production, 276, 124206.

Farooq F, Nasir Amin M, Khan K, Rehan Sadiq M, Faisal Javed M, Aslam F, Alyousef R (2020) Comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Appl Sci 10(20):7330

Flatt RJ, Roussel N, Cheeseman CR (2012) Concrete: An eco material that needs to be improved. J Eur Ceram Soc 32(11):2787–2798

Gartner, E.M. (2011). Potential improvements in cement sustainability. In Proceedings of the 31st Cement and Concrete Science Conference Novel Developments and Innovation in Cementitious Materials, London, UK, 12 September; pp. 12–13.

Golafshani EM, Behnood A (2021) Predicting the mechanical properties of sustainable concrete containing waste foundry sand using multi-objective ANN approach. Constr Build Mater 291:123314. https://doi.org/10.1016/j.conbuildmat.2021.123314

Hamoud A, Hashim AS, Awadh WA (2018) Predicting student performance in higher education institutions using decision tree analysis. International Journal of Interactive Multimedia and Artificial Intelligence 5:26–31

Indian Road Congress (IRC). (2008). Tentative guidelines for cement concrete mix design for pavements. IRC: 44, New Delhi, India.

Kandiri A, Golafshani EM, Behnood A (2020) Estimation of the compressive strength of concretes containing ground granulated blast furnace slag using hybridized multi-objective ANN and salp swarm algorithm. Constr Build Mater 248:118676. https://doi.org/10.1016/j.conbuildmat.2020.118676

Kashi H, Emamgholizadeh S, Ghorbani H (2014) Estimation of soil infiltration and cation exchange capacity based on multiple regression, ANN (RBF, MLP), and ANFIS models. Commun Soil Sci Plant Anal 45:1195–1213

Maghool F, Arulrajah A, Haghighi H, Horpibulsuk S, Du Y-J (2017) The influence of a curing regime on the geotechnical properties of ladle furnace slag as used in pavement applications. Geotechnical Frontiers DOI 10(1061/9780784480441):034

Mangi, S.A., Jamaluddin, N., Wan Ibrahim, M.H., Abdullah, A.H., Abdul Awal, A.S.M.,Sohu, S., &Ali, N. (2017). Utilization of sugarcane bagasse ash in concrete as partial replacement of cement. IOP Conf. Ser. Mater. Sci. Eng, 271.

Manso JM, Losañez M, Polanco JA, Gonzalez JJ (2005) Ladle furnace slag in construction. J Mater Civ Eng 17(5):513–518. https://doi.org/10.1061/(asce)0899-1561

Mehta A, Siddique R (2018) Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: strength and permeability properties. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.08.313

Mehta, P.K. (1997). Bringing the concrete industry into a new era of sustainable development. In Proceedings of the Symposium on Advances in Concrete Science and Technology, Fifth CANMET/ACI International Conference Proceedings, Rome, Italy, pp. 49–67.

Mohammed A, Burhan L, Ghafor K, Sarwar W, Mahmood W (2020c) Artificial neural network (ANN), M5P-tree, and regression analyses to predict the early age compression strength of concrete modified with DBC-21 and VK-98 polymers. Neural Comput Appl. https://doi.org/10.1007/s00521-020-05525-y

Mohammed, A., Rafiq, S., Sihag, P., Kurda, R., & Mahmood, W. (2020a). Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. Journal of Building Engineering, 101851.

Mohammed A, Rafiq S, Sihag P, Mahmood W, Ghafor K, Sarwar W (2020b) ANN, M5P-tree model, and nonlinear regression approaches to predict the compression strength of cement-based mortar modified by quicklime at various water/cement ratios and curing times. Arab J Geosci 13(22):1–16

Quinlan, J.R. (1987). Generating production rules from decision trees. Inijcai, (Vol. 87, pp. 304–307). http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.98.9054&rep=rep1&type=pdf

Quinlan, J.R. (1992). Learning with continuous classes. In5th Australian joint conference on artificial intelligence. (Vol. 92, pp. 343–348). https://doi.org/10.1142/9789814536271

Rađenović A, Malina J, Sofilić T (2013) Characterization of ladle furnace slag from carbon steel production as a potential adsorbent. Adv Mater Sci Eng 1–6. https://doi.org/10.1155/2013/198240

Raghavendra T, Udayashankar BC (2014) Flow and strength characteristics of CLSM using ground granulated blast furnace slag. J Mater Civ Eng 26(9):04014050. https://doi.org/10.1061/(asce)mt.1943-5533.0000927

Sihag P, Fatemeh E, Balraj S, Isha E, Hossein B (2019) Modelling unsaturated hydraulic conductivity by hybrid soft computing techniques. Springer-Verlag GmbH Germany, Part of Springer Nature. https://doi.org/10.1007/s00500/019-03847-1

Sihag P, Suthar M, Mohanty S (2021) Estimation of UCS-FT of dispersive soil stabilized with fly ash, cement clinker and GGBS by artificial intelligence. Iran J Sci Technol 45(2):901–912. https://doi.org/10.1007/s40996-019-00329-0

Sobhani, J., Ejtemaei, M., Sadrmomtazi, A., &Mirgozar, M.A. (2019). Modeling flexural strength EPS light weight concrete using regression, neural network and ANFIS. International Journal of optimization in Civil Engineering, 9(2): 313–329.URL: http://ijoce.just.ac.ir/article-1-392-en.html.

Suthar M, Aggarwal P (2018) Predicting CBR value of stabilized pond ash with lime and lime sludge using ANN and MR models. International Journal of Geosynthetics and Ground Engineering 4(1):6.https://doi.org/10.1007/s40891-017-0125-3

Suthar, M., & Aggarwal, P. (2019). Modeling CBR value using RF and M5P techniques. MENDEL, 25(1), 73–78. https://doi.org/10.13164/mendel.2019.1.073

Suthar M (2020a) Applying several machine learning approaches for prediction of unconfined compressive strength of stabilized pond ashes. Neural Computing and Application 32:9019–9028. https://doi.org/10.1007/s00521-019-04411-6

Suthar M (2020b) Modeling of UCS value of stabilized pond ashes using adaptive neuro-fuzzy inference system and artificial neural network. Soft Comput 24:14561–14575. https://doi.org/10.1007/s00500-020-04806-x

Witten, I.H., Frank, E., Hall, M.A., & Pal, C.J. (2005). Data Mining: Practical machine learning tools and techniques. Morgan Kaufmann.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Amjad Kallel

Rights and permissions

About this article

Cite this article

Rani, K., Suthar, M., Sihag, P. et al. Experimental investigation and prediction of strength development of GGBFS-, LFS- and SCBA-based green concrete using soft computing techniques. Arab J Geosci 14, 2612 (2021). https://doi.org/10.1007/s12517-021-08869-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08869-4