Abstract

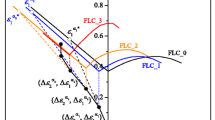

The forming limit diagram (FLD) is commonly used in the forming industry to predict localized necking in sheet metals. However, experimental and mathematical determination of forming limit curves is based on in-plane deformation without taking a bending component into account. This paper addresses the question whether a forming limit diagram predicts localized necking too conservatively or too liberally for different amounts of superimposed bending. Furthermore a methodology is proposed on how to determine the influence of bending quantitatively and how to incorporate the results into a FLD. Finite element analysis (FEA) is used to model the angular stretch bend test (ASBT), where a strip of sheet metal is locked at both ends and a tool with a radius stretches and bends the center of the strip until failure. By using different radii, the sample is exposed to different amounts of superimposed bending during the stretching. The FEA model is verified by experimental work using a dual phase steel (DP600). Applying a strain rate dependent identification method for determining the onset of localized necking, the FEA model is utilized to access the forming limit strains for different stretch bending conditions. Thereby the Keeler-Brazier FLD is extended by a third dimension, the superimposed bending dimension, to assess the effect of bending on the forming limit of sheet metal parts. The more severe the superimposed bending, the higher the formability of the steel.

Similar content being viewed by others

References

Keeler SP, Brazier WG (1975) Relationship between laboratory material characterization and press-shop formability

Hora P, Tong L, Berisha B (2013) Modified maximum force criterion, a model for the theoretical prediction of forming limit curves. Int J Mater Form 6(2):267–279

Tharrett MR, Stoughton TB (2003) Stretch-bend forming limits of 1008 AK steel

Kitting D, Koplenig M, Ofenheimer A, Pauli H, Till ET (2009) Application of a “Concave-Side Rule” approach for assessing formability of stretch-bent steel sheets. Int J Mater Form 2(1):427–430

Neuhauser FM, Terrazas OR, Manopulo N, Hora P, Van Tyne CJ (2016) Stretch bending - the plane within the sheet where strains reach the forming limit curve. In: IOP Conference series: Materials science and engineering, vol 159

Kitting D, Ofenheimer A, Pauli H, Till ET (2010) A phenomenological concept to predict formability in stretch-bending forming operations. Int J Mater Form 3(1):1163–1166

Kitting D, Ofenheimer A, Pauli H, Till ET (2011) Experimental characterization of stretch-bending formability of ahss sheets. AIP Conference Proceedings 1353(1):1589–1594

Levy BS, Van Tyne CJ (2009) Predicting breakage on a die radius with a straight bend axis during sheet forming. J Mater Process Technol 209(4):2038–2046

de Kruijf NE, Peerlings RHJ, Geers MGD (2009) An analysis of sheet necking under combined stretching and bending. Int J Mater Form 2(1):845–848

Xia C, Zeng D (2008) Sheet metal forming limit under stretch-bending. In: Proceedings of the 2008 International Manufacturing Science and Engineering Conference, pp 1–7

Vallellano C, Morales D, Martinez AJ, Garcia-Lomas FJ (2010) On the use of concave-side rule and critical-distance methods to predict the influence of bending on sheet-metal formability. Int J Mater Form 3 (1):1167–1170

Morales-Palma D, Vallellano C, García-Lomas FJ (2013) Assessment of the effect of the through-thickness strain/stress gradient on the formability of stretch-bend metal sheets. Mater Des 50:798–809

Hora P, Tong L (2008) Theoretical prediction of the influence of curvature and thickness on the enhanced modified maximum force criterion. Numisheet 7:205–210

Volk W, Hora P (2011) New algorithm for a robust user- independent evaluation of beginning instability for the experimental FLC determination. Int J Mater Form 4(3):339–346

Acknowledgements

The authors thank the Advanced Steel Processing and Products Research Center (ASPPRC) at Colorado School of Mines for the support for this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Neuhauser, F.M., Terrazas, O., Manopulo, N. et al. The bending dependency of forming limit diagrams. Int J Mater Form 12, 815–825 (2019). https://doi.org/10.1007/s12289-018-1452-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-018-1452-1