Abstract

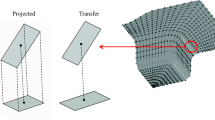

This paper presents the application of multi scale techniques to the simulation of sheet metal forming using the one-step method. When a blank flows over the die radius, it undergoes a complex cycle of bending and unbending. First, we describe an original model for the prediction of residual plastic deformation and stresses in the blank section. This model, working on a scale about one hundred times smaller than the element size, has been implemented in SIMEX, one-step sheet metal forming simulation code. The utilisation of this multi-scale modeling technique improves greatly the accuracy of the solution. Finally, we discuss the implications of this analysis on the prediction of springback in metal forming.

Similar content being viewed by others

References

Zhou D, Wagoner RH (1995) Development and application of sheet metal forming simulation. J Mater Process Technol 50:1–16

Makinouchi A (1996) Sheet metal forming simulation in industry. J Mater Process Technol 60:19–26

El Mouatassim M, Thomas B, Jameux J-P, DiPasquale E (1995) An industrial finite element code for one-step simulation of sheet metal forming. In: Shen, Dawson (eds) Simulation of materials processing: theory, methods and applications. Balkema, Rotterdam

Nine HD (1982) New drawbead concepts for sheet metal forming. J Appl Met Work 2:3

Firat M, Kaftanouglu B, Eser O (2008) Sheet metal forming analyses with an emphasis on the springback deformation. J Mater Process Technol 196:135–148

Sanchez LR (2010) Modeling of springback, strain rate and Bauschinger effects for two dimensional steady state cyclic flow of sheet metal subjected to bending under tension. Int J Mech Sci 53:429–439

Nanu N, Brabie G (2012) Analytical model for prediction of springback paramerers n the case of U stretch-bending process as a function of stresses distribution in the sheet thicknesss. Int J Mech Sci 64:11–21

Ghaei A, Green DE, Aryanpour A (2015) Springback simulation of advanced high strength steels considering nonlinear elastic unloading-reloading behavior. Mater Des 88:461–470

Lemaitre J, Chaboche J-L (1994) Mechanics of solid materials. Cambridge Univ. Press, Cambridge

Malvern LE (1969) Introduction to the mechanics of a continuous medium. Prentice-Hall

Acknowledgements

The author would like to thank the RENAULT participants to MACARENA project (in particular Mr. Pierre LORY) for their cooperation.

Funding information

Part of the work presented has been carried out within the framework of the RNTL MACARENA project (grant number 02 4 93 0305). The support of the French Ministry of Industry is dutifully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Rights and permissions

About this article

Cite this article

Di Pasquale, E. Semi-analytical models for flexure deformation in one-step simulation of sheet metal forming. Int J Mater Form 12, 197–210 (2019). https://doi.org/10.1007/s12289-017-1376-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-017-1376-1