Abstract

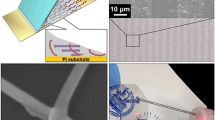

The thermal decomposition synthesis of long copper nanowires (CuNWs) was achieved by controlling the synthesis parameters. A detailed study was performed to determine the effect of the molar ratio of copper chloride to nickel acetylacetonate, temperature, and stirring rate on the final shape of the products. Transparent electrodes (TEs) were fabricated by wet treatment with acetic acid (AA), without using a sintering process. The low oxidation stability and high surface roughness are the main disadvantages of the CuNW TEs, which limit their applications. In order to overcome these issues, we prepared CuNW/polymer composite TEs by partial embedding of the CuNWs into poly(methyl methacrylate) (PMMA) on poly(ethylene terephthalate) (PET) substrates. The CuNW/PMMA composite TEs exhibit excellent optoelectronic performance (91.3% at 100.7 Ω/sq), low surface roughness (4.6 nm in height), and good mechanical and chemical stability as compared with CuNW TEs. On the basis of these properties, we believe that CuNW-based composite TEs could serve as low-cost materials for a wide range of new optoelectronic devices.

Similar content being viewed by others

References

Gordon, R. G. Criteria for choosing transparent conductors. MRS Bull. 2000, 25, 52–57.

Gaynor, W.; Lee, J.-Y.; Peumans, P. Fully solution-processed inverted polymer solar cells with laminated nanowire electrodes. ACS Nano 2010, 4, 30–34.

Madaria, A. R.; Kumar, A.; Zhou, C. W. Large scale, highly conductive and patterned transparent films of silver nanowires on arbitrary substrates and their application in touch screens. Nanotechnology 2011, 22, 245201.

Van De Lagemaat, J.; Barnes, T. M.; Rumbles, G.; Shaheen, S. E.; Coutts, T. J.; Weeks, C.; Levitsky, I.; Peltola, J.; Glatkowski, P. Organic solar cells with carbon nanotubes replacing In2O3: Sn as the transparent electrode. Appl. Phys. Lett. 2006, 88, 233503.

Leterrier, Y.; Médico, L.; Demarco, F.; Månson, J.-A. E.; Betz, U.; Escola, M. F.; Olsson, M. K.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Films 2004, 460, 156–166.

Minami, T. Transparent conducting oxide semiconductors for transparent electrodes. Semicond. Sci. Technol. 2005, 20, S35.

Hecht, D. S.; Hu, L. B.; Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Adv. Mater. 2011, 23, 1482–1513.

Hong, W. J.; Xu, Y. X.; Lu, G. W.; Li, C.; Shi, G. Q. Transparent graphene/PEDOT–PSS composite films as counter electrodes of dye-sensitized solar cells. Electrochem. Commun. 2008, 10, 1555–1558.

Doherty, E. M.; De, S.; Lyons, P. E.; Shmeliov, A.; Nirmalraj, P. N.; Scardaci, V.; Joimel, J.; Blau, W. J.; Boland, J. J.; Coleman, J. N. The spatial uniformity and electromechanical stability of transparent, conductive films of single walled nanotubes. Carbon 2009, 47, 2466–2473.

Hu, L.; Hecht, D. S.; Grüner, G. Percolation in transparent and conducting carbon nanotube networks. Nano Lett. 2004, 4, 2513–2517.

Tung, V. C.; Chen, L.-M.; Allen, M. J.; Wassei, J. K.; Nelson, K.; Kaner, R. B.; Yang, Y. Low-temperature solution processing of graphene−carbon nanotube hybrid materials for high-performance transparent conductors. Nano Lett. 2009, 9, 1949–1955.

Azulai, D.; Belenkova, T.; Gilon, H.; Barkay, Z.; Markovich, G. Transparent metal nanowire thin films prepared in mesostructured templates. Nano Lett. 2009, 9, 4246–4249.

Wu, H.; Hu, L. B.; Rowell, M. W.; Kong, D. S.; Cha, J. J.; McDonough, J. R.; Zhu, J.; Yang, Y.; McGehee, M. D.; Cui, Y. Electrospun metal nanofiber webs as high-performance transparent electrode. Nano Lett. 2010, 10, 4242–4248.

Leem, D. S.; Edwards, A.; Faist, M.; Nelson, J.; Bradley, D. D. C.; de Mello, J. C. Efficient organic solar cells with solution-processed silver nanowire electrodes. Adv. Mater. 2011, 23, 4371–4375.

Hu, L. B.; Kim, H. S.; Lee, J.-Y.; Peumans, P.; Cui, Y. Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 2010, 4, 2955–2963.

Scardaci, V.; Coull, R.; Lyons, P. E.; Rickard, D.; Coleman, J. N. Spray deposition of highly transparent, low-resistance networks of silver nanowires over large areas. Small 2011, 7, 2621–2628.

Won, Y.; Kim, A.; Lee, D.; Yang, W.; Woo, K.; Jeong, S.; Moon, J. Annealing-free fabrication of highly oxidationresistive copper nanowire composite conductors for photovoltaics. NPG Asia Mater. 2014, 6, e105.

Guo, H. Z.; Lin, N.; Chen, Y. Z.; Wang, Z. W.; Xie, Q. S.; Zheng, T. C.; Gao, N.; Li, S. P.; Kang, J.; Cai, D. J. et al. Copper nanowires as fully transparent conductive electrodes. Sci. Rep. 2013, 3, 2323.

Rathmell, A. R.; Wiley, B. J. The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates. Adv. Mater. 2011, 23, 4798–4803.

Rathmell, A. R.; Bergin, S. M.; Hua, Y. L.; Li, Z. Y.; Wiley, B. J. The growth mechanism of copper nanowires and their properties in flexible, transparent conducting films. Adv. Mater. 2010, 22, 3558–3563.

Lee, J.; Lee, I.; Kim, T. S.; Lee, J. Y. Efficient welding of silver nanowire networks without post-processing. Small 2013, 9, 2887–2894.

Celle, C.; Mayousse, C.; Moreau, E.; Basti, H.; Carella, A.; Simonato, J.-P. Highly flexible transparent film heaters based on random networks of silver nanowires. Nano Res. 2012, 5, 427–433.

Mayousse, C.; Celle, C.; Moreau, E.; Mainguet, J.-F.; Carella, A.; Simonato, J.-P. Improvements in purification of silver nanowires by decantation and fabrication of flexible transparent electrodes. Application to capacitive touch sensors. Nanotechnology 2013, 24, 215501.

Coskun, S.; Selen Ates, E.; Unalan, H. E. Optimization of silver nanowire networks for polymer light emitting diode electrodes. Nanotechnology 2013, 24, 125202.

Gaynor, W.; Burkhard, G. F.; McGehee, M. D.; Peumans, P. Smooth nanowire/polymer composite transparent electrodes. Adv. Mater. 2011, 23, 2905–2910.

Zeng, X. Y.; Zhang, Q. K.; Yu, R. M.; Lu, C. Z. A new transparent conductor: Silver nanowire film buried at the surface of a transparent polymer. Adv. Mater. 2010, 22, 4484–4488.

Hu, L. B.; Wu, H.; Cui, Y. Metal nanogrids, nanowires, and nanofibers for transparent electrodes. MRS Bull. 2011, 36, 760–765.

Guo, H. Z.; Lin, N.; Chen, Y. Z.; Wang, Z. W.; Xie, Q. S.; Zheng, T. C.; Gao, N.; Li, S. P.; Kang, J.; Cai, D. J. et al. Copper nanowires as fully transparent conductive electrodes. Sci. Rep. 2013, 3, 2323.

Choi, H.; Park, S.-H. Seedless growth of free-standing copper nanowires by chemical vapor deposition. J. Am. Chem. Soc. 2004, 126, 6248–6249.

Zhao, Y. X.; Zhang, Y.; Li, Y. P.; Yan, Z. F. Soft synthesis of single-crystal copper nanowires of various scales. New J. Chem. 2012, 36, 130–138.

Gao, T.; Meng, G. W.; Wang, Y. W.; Sun, S. H.; Zhang, L. D. Electrochemical synthesis of copper nanowires. J. Phys.: Condens. Matter 2002, 14, 355.

Molares, M. T.; Buschmann, V.; Dobrev, D.; Neumann, R.; Scholz, R.; Schuchert, I. U.; Vetter, J. Single-crystalline copper nanowires produced by electrochemical deposition in polymeric ion track membranes. Adv. Mater. 2001, 13, 62–65.

Chang, Y.; Lye, M. L.; Zeng, H. C. Large-scale synthesis of high-quality ultralong copper nanowires. Langmuir 2005, 21, 3746–3748.

Mayousse, C.; Celle, C.; Carella, A.; Simonato, J.-P. Synthesis and purification of long copper nanowires. Application to high performance flexible transparent electrodes with and without PEDOT:PSS. Nano Res. 2014, 7, 315–324.

Chen, J. Y.; Zhou, W. X.; Chen, J.; Fan, Y.; Zhang, Z. Q.; Huang, Z. D.; Feng, X. M.; Mi, B. X.; Ma, Y. W.; Huang, W. Solution-processed copper nanowire flexible transparent electrodes with PEDOT: PSS as binder, protector and oxidelayer scavenger for polymer solar cells. Nano Res. 2015, 8, 1017–1025.

Ye, S. R.; Rathmell, A. R.; Stewart, I. E.; Ha, Y. C.; Wilson, A. R.; Chen, Z. F.; Wiley, B. J. A rapid synthesis of high aspect ratio copper nanowires for high-performance transparent conducting films. Chem. Commun. 2014, 50, 2562–2564.

Cheng, Y.; Wang, S. L.; Wang, R. R.; Sun, J.; Gao, L. Copper nanowire based transparent conductive films with high stability and superior stretchability. J. Mater. Chem. C 2014, 2, 5309–5316.

Song, J. Z.; Li, J. H.; Xu, J. Y.; Zeng, H. B. Superstable transparent conductive Cu@Cu4Ni nanowire elastomer composites against oxidation, bending, stretching, and twisting for flexible and stretchable optoelectronics. Nano Lett. 2014, 14, 6298–6305.

Guo, H. Z.; Chen, Y. Z.; Ping, H. M.; Jin, J. R.; Peng, D.-L. Facile synthesis of Cu and Cu@Cu–Ni nanocubes and nanowires in hydrophobic solution in the presence of nickel and chloride ions. Nanoscale 2013, 5, 2394–2402.

Lee, C.; Kim, N. R.; Koo, J.; Lee, Y. J.; Lee, H. M. Cu-Ag core–shell nanoparticles with enhanced oxidation stability for printed electronics. Nanotechnology 2015, 26, 455601.

Kim, N. R.; Shin, K.; Jung, I.; Shim, M.; Lee, H. M. Ag–Cu bimetallic nanoparticles with enhanced resistance to oxidation: A combined experimental and theoretical study. J. Phys. Chem. C 2014, 118, 26324–26331.

Personick, M. L.; Langille, M. R.; Zhang, J.; Mirkin, C. A. Shape control of gold nanoparticles by silver underpotential deposition. Nano Lett. 2011, 11, 3394–3398.

Liu, M. Z.; Guyot-Sionnest, P. Mechanism of silver(I)-assisted growth of gold nanorods and bipyramids. J. Phys. Chem. B 2005, 109, 22192–22200.

Carenco, S.; Boissière, C.; Nicole, L.; Sanchez, C.; Le Floch, P.; Mézailles, N. Controlled design of size-tunable monodisperse nickel nanoparticles. Chem. Mater. 2010, 22, 1340–1349.

Li, Y.; Afzaal, M.; O'Brien, P. The synthesis of amine-capped magnetic (Fe, Mn, Co, Ni) oxide nanocrystals and their surface modification for aqueous dispersibility. J. Mater. Chem. 2006, 16, 2175–2180.

van Embden, J.; Chesman, A. S. R.; Jasieniak, J. J. The heat-up synthesis of colloidal nanocrystals. Chem. Mater. 2015, 27, 2246–2285.

Bhatt, A. I.; Mechler, Á.; Martin, L. L.; Bond, A. M. Synthesis of Ag and Au nanostructures in an ionic liquid: Thermodynamic and kinetic effects underlying nanoparticle, cluster and nanowire formation. J. Mater. Chem. 2007, 17, 2241–2250.

Hong, B. H.; Bae, S. C.; Lee, C.-W.; Jeong, S.; Kim, K. S. Ultrathin single-crystalline silver nanowire arrays formed in an ambient solution phase. Science 2001, 294, 348–351.

Bergin, S. M.; Chen, Y. H.; Rathmell, A. R.; Charbonneau, P.; Li, Z. Y.; Wiley, B. J. The effect of nanowire length and diameter on the properties of transparent, conducting nanowire films. Nanoscale 2012, 4, 1996–2004.

Araki, T.; Jiu, J. T.; Nogi, M.; Koga, H.; Nagao, S.; Sugahara, T.; Suganuma, K. Low haze transparent electrodes and highly conducting air dried films with ultra-long silver nanowires synthesized by one-step polyol method. Nano Res. 2014, 7, 236–245.

Jiu, J.; Araki, T.; Wang, J.; Nogi, M.; Sugahara, T.; Nagao, S.; Koga, H.; Suganuma, K.; Nakazawa, E.; Hara, M. et al. Facile synthesis of very-long silver nanowires for transparent electrodes. J. Mater. Chem. A 2014, 2, 6326–6330.

Rathmell, A. R.; Nguyen, M.; Chi, M. F.; Wiley, B. J. Synthesis of oxidation-resistant cupronickel nanowires for transparent conducting nanowire networks. Nano Lett. 2012, 12, 3193–3199.

Yu, Z. B.; Niu, X. F.; Liu, Z. T.; Pei, Q. B. Intrinsically stretchable polymer light-emitting devices using carbon nanotube-polymer composite electrodes. Adv. Mater. 2011, 23, 3989–3994.

De, S.; Lyons, P. E.; Sorel, S.; Doherty, E. M.; King, P. J.; Blau, W. J.; Nirmalraj, P. N.; Boland, J. J.; Scardaci, V.; Joimel, J. et al. Transparent, flexible, and highly conductive thin films based on polymer−nanotube composites. ACS Nano 2009, 3, 714–720.

Stewart, I. E.; Rathmell, A. R.; Yan, L.; Ye, S. R.; Flowers, P. F.; You, W.; Wiley, B. J. Solution-processed copper–nickel nanowire anodes for organic solar cells. Nanoscale 2014, 6, 5980–5988.

Stewart, I. E.; Ye, S. R.; Chen, Z. F.; Flowers, P. F.; Wiley, B. J. Synthesis of Cu–Ag, Cu–Au, and Cu–Pt core–shell nanowires and their use in transparent conducting films. Chem. Mater. 2015, 27, 7788–7794.

Chen, J. Y.; Chen, J.; Li, Y.; Zhou, W. X.; Feng, X. M.; Huang, Q. L.; Zheng, J. G.; Liu, R. Q.; Ma, Y. W.; Huang, W. Enhanced oxidation-resistant Cu-Ni core–shell nanowires: Controllable one-pot synthesis and solution processing to transparent flexible heaters. Nanoscale 2015, 7, 16874–16879.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Chu, C.R., Lee, C., Koo, J. et al. Fabrication of sintering-free flexible copper nanowire/polymer composite transparent electrodes with enhanced chemical and mechanical stability. Nano Res. 9, 2162–2173 (2016). https://doi.org/10.1007/s12274-016-1105-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-016-1105-y