Abstract

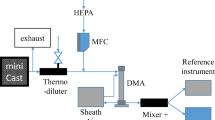

The particle size distribution and particle number (PN) concentration emitted by internal combustion engine are a subject of significant environmental concern because of their adverse health effects and environmental impact. This subject has recently attracted the attention of the Particle Measurement Programme (PMP). In 2007, the UN-ECE GRPE PMP proposed a new method to measure particle emissions in the diluted exhaust of automotive engines and a regulation limit (<6.0×1011 #/km, number of particles). The specific PN regulation of spark-ignited combustion engine will be regulated starting on September 1, 2014 (EURO 6). In this study, three types of LPG supply systems (a mixer system and a multi-point injection system with gas-phase or liquid-phase LPG fuel) were used for a comparison of the particulate emission characteristics, including the nano-sized particle number density. Each of the three LPG vehicles with various LPG injection systems contained a multi-cylinder engine with same displacement volumes of 2,000 cm3 and a three-way catalytic converter. The test fuel that was used in this study for the spark-ignited combustion engine was n-butane basis LPG fuel, which is primarily used for taxi vehicles in Korea. The characteristics of nano-particle size distribution and number concentration of particle sizes ranging from 20 to 1,000 nm (aerodynamic diameter) that were emitted from the three LPG vehicles with various LPG supply systems were investigated by using a condensation particle counter (CPC), which is recommended by the PMP under both the NEDC and FTP-75 test modes on a chassis dynamometer. The experimental results indicate that the PN emission characteristics that were obtained by the CPC system using the PMP procedure are sufficiently reliable compared to other regulated emissions. Additionally, the sources of PN emissions in ascending order of magnitude are as follows: mixer type, gas-phase LPG injection (LPGi) and liquid-phase LPG injection (LPLi) passenger vehicles. The liquid-phase LPG injection system produced relatively large particle sizes and number concentrations compared to the gaseous system, regardless of the vehicle driving cycle. This phenomenon can be explained by unburned micro-fuel droplets that were generated due to a relatively short homogeneous fuel-air mixture duration in the engine intake manifold. Also the particle number emissions from the LPG vehicle were influenced by the vehicle driving cycle.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

ACEA Research Report (2002). Programme on emissions of fine particles from passenger cars. ACEA.

Ali Khan, M. (2006). Optimization of LPG throttle-body injection system for improved efficiency. emissions and air-fuel mixing, FISITA Paper No. 20068154.

Boretti, A. (2009). Development of a direct injection high efficiency liquid phase LPG spark ignition engine. SAE Paper No. 2009-01-1881.

Donaldson, K., Liu, X. Y. and MacNee, W. (1998). Ultrafine (Nanometer) particle mediated lung injury. J. Aerosol Science, 29, 553–560.

EU Legislative Acts and Other Instruments (2007). Regulation of the European Parliament and of the Council on type approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information. EU Legislative Acts and Other Instruments, PE-CONS 3602/07.

Fuel quality standards for Liquefied Petroleum Gas in Korea. Korea Institute of Petroleum Management, (http://www.kpetro.or.kr/eng/standards/standards_02.jsp).

Goto, S., Wakasa, R. and Lee, D. (2001). Research trends of LPG-fueled engine system. J. Society of Automotive Engineers of Japan 55,5, 30–37.

Health Effects Institute (2002). Understanding the Health Effects of Components of the Particulate Matter Mix: Progress and Next Steps. Health Effects Institute.

Kasper, M., Matter, U. and Burtscher, H. (2001). NanoMet: On-line characterization of nanoparticle size and composition. SAE Paper No. 2001-01-1998.

Kim, H. S., Kim, S. S., Cho, J. M., Cho, G. B., Sung, N. W. and Jeong, Y. I. (2005). Measurement of size distribution of diesel particles: Effects of instruments, dilution methods and measuring positions. Int. J. Automotive Technology 6,2, 119–124.

Kittelson, D. B. (1998). Engines and nanoparticles: A review. J. Aerosol Science, 29, 575–588.

Korea LPG Association (2009). Statistical Review of Global LP Gas. Korea LPG Association. 2009-Report.

Lee, E. J., Park, J. W., Huh, K. Y., Choi, J. J. and Bae, S. D. (2003). Simulation of fuel/air mixture formation for heavy duty liquid phase LPG injection engines. SAE Paper No. 2003-01-0636.

Lee, J. W., Jeong, Y. I., Jung, M. W., Cha, K. O., Kwon, S. I., Kim, J. C. and Park, S. S. (2008). Experimental investigation and comparison of nano-particle emission characteristics in light-duty vehicles for two different fuels. Int. J. Automotive Technology 9,4, 397–403.

Mizushima, N., Sato, S., Yamamoto, T., Konagai, G., Ogawa, Y., Sawut, U., Kawayoko, K. and Takigawa, B. (2009). Combustion characteristics and performance increase of an LPG-SI engine with liquid fuel injection system. JSAE Paper No. 20093890.

Morita, K. (2003). Automotive power source in 21st century. JSAE Review, 24, 1–5.

Myung, C. L., Lee, H., Choi, K., Lee, Y. J. and Park, S. (2009). Effects of gasoline, diesel, LPG and low-carbon fuels and various certification modes on nanoparticle emission characteristics in light-duty vehicles. Int. J. Automotive Technology 10,5, 537–544.

Pagan, J. (1999). Study of particle size distributions emitted by a diesel engine. J. Fuels and Lubricants (SAE Transactions) 108,4, 557–562.

Park, K. and Han, S. (2004). The ignition characteristics for the direct liquid injection combustion in LPG engine. FISITA Paper No. 20042357.

SAE Handbook (1994). Chemical methods for the measurement of nonregulated diesel emissions. SAE 1994-Handbook.

Sierens, R. (1992). An experimental and theoretical study of liquid LPG injection. SAE Paper No. 922363.

Van der Steen, M., De Rijke, J. and Seppen, J. J. (1996). Stoichiometric and lean burn heavy-duty gas engines: A dilemma between exhaust emissions and fuel consumption. TNO-Paper No. VM9605.

Watson, H. C. and Phuong, P. X. (2007). Why liquid phase LPG port injection has superior power and efficiency to gas phase port injection. SAE Paper No. 2007-01-3552.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.W., Do, H.S., Kweon, S.I. et al. Effect of various LPG supply systems on exhaust particle emission in spark-ignited combustion engine. Int.J Automot. Technol. 11, 793–800 (2010). https://doi.org/10.1007/s12239-010-0094-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-010-0094-1