Abstract

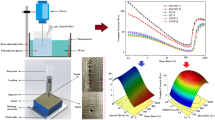

Glass wool felt (GWF) made from glass wool and phenolic resin adhesive is prospected to have a promising future in sound insulation of aircraft. In this paper, the GWF was fabricated by centrifugal-spinneret-blow (CSB), and there were two different methods to guide the glass wool, which were free float type (FFT) and guided swing cylinder (GSC), with GSC being designed as uniform processes. The tensile strength and hydrophobicity properties of GWF from these two methods were compared. The experimental results suggested that tensile strength and hydrophobicity properties of GWF by GSC were greater, with non-uniformity being 5 %. The tensile strength, breaking length and elastic deformation of GWF were obtained during the GWF manufactured by GSC with fibers being in 2-D distribution, and the phase difference of the swing cylinders being π/2+2kπ. The maximum static contact angle and minimum water repellency of GWF produced by GSC were 141 ° and 15 g, while for FFT they were 100 ° and 26.92 g, respectively. The uniformity of GWF’s smooth surface was accompanied by excellent hydrophobicity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

K. É. Goryainov, R. M. Serafimova, and V. I. Pestsov, Glass Ceram., 34, 294 1977.

H. Ku, H. Wang, N. Pattarachaiyakoop, and M. Trada, Compos. Pt. B-Eng., 42, 856 2011.

B. Champagne and R. Angers, Int. J. Powder Metall. Powder Technol., 16, 359 1980.

Y. Z. Liu, K. Minagawa, H. Kakisawa, and K. Halada, Int. J. Powder Metall., 39, 29 2003.

H. L. Cox, Br. J. Appl. Phys., 3, 72 1952.

C. F. Yang, Ph.D. Thesis, University of Washington, 1975.

M. Rigdahl, B. Westerlind, and H. Hollmark, J. Mater. Sci., 19, 3945 1984.

S. Heyden, Ph.D. Thesis, Lund University, 2000.

N. Venkateshwaran, A. Elayaperumal, and G. K. Sathiya, Compos. Pt. B-Eng., 43, 793 2012.

A. Ridruejo, C. González, and J. Lorca, J. Mech. Phys. Solids, 58, 1628 2010.

M. S. Rizvi, P. Kumar, D. S. Katti, and A. Pal, Acta Biomater., 8, 4111 2012.

A. Kulachenko, T. Denoyelle, S. Galland, and S. B. Lindström, Cellulose, 19, 793 2012.

S. Borodulina, A. Kulachenko, S. Galland, and M. Nygårds, J. Pulp. Pap. Sci., 27, 318 2012.

Y. Z. Liu, Mater. Sci. Technol., 18, 929 2002.

B.-Y. Chen, Y.-S. Wang, H. Y. Mi, P. Yu, T. R. Kuang, X. F. Peng, and J. S. Wen, J. Appl. Polym. Sci., 131, 41181 2014.

Y. Zhaogang, G. Awuti, C. Yi, Z. Jing, W. Boshen, W. Jianchen, L. Wanliang, Z. Xuan, and Z. Qiang, J. Chinese Pharm. Sci., 15, 69 2006.

L. Chang, M. Howdyshell, W. C Liao, C. L. Chiang, D. GallegoPerez, Z. Yang, W. Lu, J. C. Byrd, N. Muthusamy, L. J. Lee, and R. Sooryakumar, Small, 11, 1818 2015.

V. Tarnow, J. Acoust. Soc. Am., 111, 2735 2002.

B. Sirok, B. Blagojevic, and M. Novak, Glass Technol., 43, 188 2002.

B. Blagojevic and B. Sirok, Glass Technol., 43, 120 2002.

S. V. Fridrikh, J. H. Yu, M. P. Brenner, and G. C. Rutledge, Phys. Rev. Lett., 90, 1 2003.

E. P. S. Tan and C. T. Lim, Compos. Sci. Technol., 66, 1102 2006.

J. L. Thomasson and M. A. Vlug, Compos. Pt. A-Appl. Sci. Manuf., 127, 477 1996.

M. Latva-Kokko and H. Rothman, Phys. Rev. E, 72, 046701 2005.

D. Janssen, R. D. Palma, S. Verlaak, P. Heremans, and W. Dehaen, Thin Solid Films, 515, 1433 2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Chen, Z., Chen, Z. et al. Processing technique and uniformity affecting tensile strength and hydrophobicity properties of glass wool felt. Fibers Polym 16, 1587–1594 (2015). https://doi.org/10.1007/s12221-015-5310-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-015-5310-1