Abstract

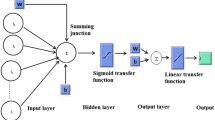

Today numerous consumers consider thermal comfort to be one of the most significant attributes when purchasing textile and apparel products, so there is a need to develop a model able to simulate objectively the consumers’ perception. The global thermal comfort of stretch knitted fabrics is a multi-criteria phenomenon that requires the satisfaction of several properties at the same time. In this paper, we used the desirability functions to evaluate the satisfaction degree of global thermal comfort. Statistical method was used to investigate the interrelationship among knit thermo-physical properties, and group them into factors. Two models of artificial neural network (general and special) have been set up to predict the global thermal comfort from structural parameters (inputs) of knitted fabrics made from pure yarn cotton (cellulose) and viscose (regenerated cellulose) fibers and plated knitted with elasthane (Lycra) fibers. A virtual leave one out approach dealing with over fitting phenomenon and allowing the selection of the optimal neural network architecture was used. By combining the strengths of statistics and fuzzy logic (data reduction and information summation) also a neural network (self-learning ability), hybrid model was developed to simulate the consumer thermal comfort perception. After that, ANN model is inverted. With a required output value and some input parameters it is possible to calculate the unknown optimum input parameter. Finally, this forecasting can help industrials to anticipate the consumer’s taste. Thus, they can adjust the knitting production parameter to reach the desired global thermal comfort to satisfy this consumer.

Similar content being viewed by others

References

Y. Li, “The Science of Clothing Comfort”, p.135, The Textile Institute, UK, 2001.

N. R. S. Hollies and R. F. G. Goldman, “Clothing Comfort-Interaction of Thermal, Ventilation, Construction and Assessment Factors”, p.189, Ann Arbor Science Publishers, Michigan, 1975.

K. Slater, J. Text. Inst., 77, 157 (1986).

Y. Li, Text. Prog., 31, 1 (2001).

H. Zhang, Ph. D. Dissertation, UCB, Berkeley, 2003.

D. A. Watkins and K. Slater, J. Text. Inst., 72, 11 (1981).

M. S. Parmar and S. K. Srivastava, Ind. J. Fiber. Text. Res., 24, 41 (1999).

L. Schacher, D. C. Adolphe, and J. Y. Drean, Int. J. Cloth. Sci. Tech., 12, 84 (2000).

M. J. Pac, M. A. Bueno, and M. Renner, Text. Res. J., 71, 806 (2001).

B. Le Pechoux, R. M. Laing, Y. Li, A. Bookset, T. K. Ghosh, and G. G. Sleivert, “The Science of Clothing Comfort”, p.138, The Textile Institute, Manchester, 2001.

N. Ozdil, A. Marmarali, and D. Kretzschmar, Int. J. Therm. Sci., 46, 1318 (2007).

A. Das and S. M. Ishtiaque, J. Text. Appar. Tech. Manag., 3, 1 (2004).

G. Ozçelik, A. Çay, and E. Kirtay, Fibres Text. East. Eur., 15, 55 (2007).

N. Ucar and T. Yilmaz, Fibres Text. East. Eur., 12, 34 (2005).

N. Oglakcioglu and A. Marmarali, Fibres Text. East. Eur., 15, 94 (2007).

R. Ciukas, A. Jovita, and K. Paulius, Fibres Text. East. Eur., 18, 89 (2010).

G. D. Šajn, K. Dimitrovski, and K. M. Bizja, Text. Res. J., 82, 1498 (2012).

S. Tezel and Y. Kavusturan, Text. Res. J., 78, 966 (2008).

S. B. Stankovic, D. Popovic, and G. B. Poparic, Polym. Test., 27, 41 (2008).

C. A. Pavko and E. U. Stankovic, Acta Chim. Slov., 57, 957 (2010).

S. E. G. Jeguirim, A. B. Dhouieb, M. Sahnoun, M. Cheikhrouhou, L. Schacher, and D. Adolphe, J. Intell. Manuf., 22, 873 (2011).

D. Bhattacharjee and V. K. Kothari, Text. Res. J., 77, 4 (2007).

F. Fayala, H. Alibi, A. Jemni, and X. Zeng, J. Eng. Fiber. Fabr., 3, 53 (2008).

A. Majumdar, J. Text. Inst., 102, 752 (2011).

H. Alibi, F. Fayala, A. Jemni, and X. Zeng, Special Topics & Reviews in Porous Media, 3, 35 (2012).

H. Alibi, F. Fayala, A. Jemni, and X. Zeng, J. Appl. Sci., 12, 2283 (2012).

H. Alibi, F. Fayala, N. Bhouri, A. Jemni, and X. Zeng, J. Text. Inst., 104, 766 (2013).

A. S. W. Wong, Y. Li, and P. K. W. Yeung, Text. Res. J., 73, 31 (2003).

A. S. W. Wong, Y. Li, and P. K. W. Yeung, Fiber J., 59, 11 (2003).

A. S. W. Wong, Y. Li, and P. K. W. Yeung, Text. Res. J., 74, 13 (2004).

A. S. W. Wong, Y. Li, and P. K. W. Yeung, J. Text. Inst., 93, 108 (2002).

C. Vigneswaran, K. Chandrasekaran, and P. Senthilkumar, J. Ind. Text., 38, 289 (2009).

A. Koblyakov, “Laboratory Practice in the Study of Textile Materials”, p.384, Mir Publishers, Moscow, 1989.

B. Das, V. K. Kothari, R. Fanguiero, and M. De Araujo, Fiber. Polym., 9, 225 (2008).

L. Hes, Vlakna a Textil, 7, 91 (2000).

L. Hes, Int. J. Cloth. Sci. Tech., 11, 105 (1999).

L. Hes, J. Hanzl, I. Dolezal, and Z. Miklas, Melliand Text. Int., 71, 679 (1990).

L. Hes and I. Dolezal, J. Text. Mash. Soc. Jpn., 42, 124 (1989).

N. Ucar and T. Yilmaz, Fibres Text. East. Eur., 12, 34 (2005).

G. Derringer and R. Suich, J. Qual. Technol., 12, 214 (1980).

Y. Oussar, G. Monari, and G. Dreyfus, Neural Comp., 16, 419 (2004).

G. Monari and G. Dreyfus, Neural Comp., 14, 1481 (2002).

F. Fayala, H. Alibi, A. Jemni, and X. Zeng, Fiber. Polym., 15, 855 (2014).

M. Tushir and S. Srivastava, Appl. Soft Comp., 10, 381 (2010).

U. Teeboonma, J. Tiansuwan, and S. Soponronnarit, J. Food. Eng., 59, 369 (2003).

J. R. Dutta, P. K. Dutta, and R. Banerjee, Process Biochem., 39, 2193 (2004).

D. S. Lee and Y. R. Pyun, Dry. Technol., 11, 1025 (1993).

D. M. Elustondo, A. S. Mujumdar, and M. J. Urbicain, Dry. Technol., 20, 381 (2002).

J. A. Hernández, D. Colorado, O. Cortés-Aburto, Y. El Hamzaoui, V. Velazquez, and B. Alonso, Appl. Therm. Eng., 50, 1399 (2013).

J. Labus, J. A. Hernández, J. C. Bruno, and A. Coronas, Renew. Energy, 39, 471 (2012).

O. Cortés, G. Urquiza, and J. A. Hernández, Appl. Energy, 86, 2487 (2009).

J. A. Hernández, Food Control, 20, 435 (2009).

Y. El-Hamzaoui, J. A. Hernández, S. Silva-Martínez, A. Bassam, A. Álvarez, and C. Lizama-Bahena, Desalination, 277, 325 (2011).

M. Laidi and S. Hanini, Int. J. Refreg., 36, 247 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fayala, F., Alibi, H., Jemni, A. et al. A new hybrid artificial intelligence approach to predicting global thermal comfort of stretch knitted fabrics. Fibers Polym 16, 1417–1429 (2015). https://doi.org/10.1007/s12221-015-1417-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-015-1417-7