Abstract

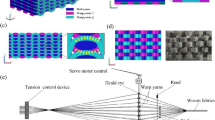

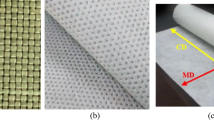

The aim of this study was to understand the ±45 ° directional off-axis tensile properties of the developed two dimensional (2D) multistitched multilayer E-glass/polyester woven composites. It was found that the off-axis tensile strength of the unstitched structure was slightly higher than those of the multistitched structures. The reason was that the multistitching process caused the filament breakages. It was also found that when the stitching direction and stitching density in structures increased, their off-axis tensile modulus decreased. Therefore, stitching directions, stitching density and stitching yarn on the composite structures were considered as important parameters. All structures under the off-axis tensile load had normal deformation, or angular deformation or shrinkage in width. In addition, both the normal deformation and the shrinkages in width occurred in most of the two and four directional stitched structures. On the other hand, four directional Kevlar® 129 yarn dense stitched E-glass/polyester structure showed only shrinkage in width after angular deformation. This could be considered as a new failure mode because of the multistitching. These results indicated that the stitching directions and density generally influenced the off-axis tensile properties of the multistitched E-glass/polyester woven composites.

Similar content being viewed by others

References

M. B. Dow and H. B. Dexter, NASA/TP-97-206234, 1997.

R. Kamiya, B. A. Cheeseman, P. Popper, and T. W. Chou, Compos. Sci. Technol., 60, 33 (2000).

T. W. Chou, “Microstructural Design of Fibre Composites”, pp.1–26, Cambridge University Press, Cambridge, 1992.

B. N. Cox, M. S. Dadkhah, W. L. Morris, and J. G. Flintoff, ACTA Metallurgica et Materialia, 42, 3967 (1994).

J. Brandt, K. Drechsler, and F. J. Arendts, Compos. Sci. Technol., 56, 381 (1996).

H. B. Dexter and G. H. Hasko, Compos. Sci. Technol., 51, 367 (1996).

K. Bilisik and B. Yilmaz, Text. Res. J., 82, 336 (2012).

M. L. Realff, Text. Res. J., 64, 135 (1994).

M. L. Realff, M. C. Boyce, and S. Backer, Text. Res. J., 67, 445 (1997).

W. D. Freeston Jr, M. M. Platt, and M. M. Schoppee, Text. Res. J., 37, 948 (1967).

A. P. Mouritz, K. H. Leong, and I. Herszberg, Compos. Part A-Appl. S., 28, 979 (1997).

A. P. Mouritz, Proc. Inst. Mech. Eng., J. Mat: Design App., 218, 87 (2004).

T. J. Kang and S. H. Lee, J. Compos. Mat., 28, 1574 (1994).

A. P. Mouritz, J. Gallagher, and A. A. Goodwin, Compos. Sci. Technol., 57, 509 (1997).

G. L. Farley and L. C. Dickinson, J. Reinf. Plast. Compos., 11, 633 (1992).

E. Wu and J. Wang, J. Compos. Mat., 29, 2254 (1995).

S. A. Tekalur, K. Shivakumar, and A. Shukla, Compos. Part B, 39, 57 (2008).

L. C. Dickinson, G. L. Farley, and M. K. Hinders, J. Comp. Mat., 33, 1002 (1999).

K. T. Tan, N. Watanabe, and Y. Iwahori, Int. J. Damage Mech., 21, 51 (2012).

K. T. Tan, N. Watanabe, Y. Iwahori, and T. Ishikawa, Compos. Part A-Appl. S., 43, 823 (2012).

R. Velmurugan and S. Solaimurugan, Compos. Sci. Tech., 67, 61 (2007).

Y. Wei and J. Zhang, Compos. Part A-Appl. S., 39, 815 (2008).

E. Wu and J. Wang, J. Compos. Mat., 29, 2254 (1995).

N. Zhao, H. Rodel, C. Herzberg, S. L. Gao, and S. Krzywinsky, Compos. Part A-Appl. S., 40, 635 (2009).

U. Beier, F. Fischer, J. K. V. Sandler, V. Altstadt, C. Weimer, and W. Buchs, Compos. Part A-Appl. S., 38, 1655 (2007).

G. L. Farley, B. L. Smith, and J. Maiden, J. Reinf. Plast. Compos., 11, 787 (1992).

C. Lee and D. Liu, J. Eng. Mat. Tech., 112, 125 (1990).

K. T. Tan, N. Watanabe, and Y. Iwahori, Int. J. Damage Mech., 21, 51 (2012).

K. T. Tan, N. Watanabe, and Y. Iwahori, Compos. Part BEng., 42, 874 (2012).

G. Chen, Z. Li, C. Kou, and L. Gui, J. Reinf. Plast. Compos., 23, 987 (2004).

C. Xiaoquan, A. M. Al-Mansour, L. Zhengneng, and K. Chenghe, J. Reinf. Plast. Compos., 24, 935 (2005).

T. C. Truong, M. Vettori, S. Lomov, and I. Verpoest, Compos. Part A-Appl. S., 36, 1207 (2005).

C. Weimer and P. Mitschang, Compos. Part A-Appl. S., 32, 1477 (2001).

L. Lee, S. R. Clark, A. P. Mouritz, M. K. Bannister, and I. Herszberg, Compos. Struct., 57, 405 (2007).

K. Bilisik, J. Reinf. Plast. Compos., 29, 1173 (2010).

M. H. Mohamed and A. K. Bilisik, U.S. Patent, 5465760 (1995).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bilisik, K., Yolacan, G. Off-axis tensile properties of multistitched plain woven E-glass/polyester composites. Fibers Polym 15, 589–598 (2014). https://doi.org/10.1007/s12221-014-0589-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-0589-x