Abstract

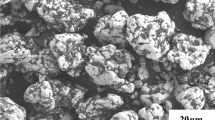

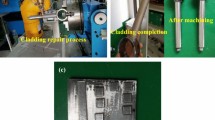

Laser cladding technology was adapted to fabricate Fe-based shape memory alloy/Nb composite coatings with 5 wt. % Nb doping amounts on 304 stainless steel to promote the microhardness and wear resistance. The SEM, XRD, optical profilometer and electrochemical workstation were used to characterize micromorphology, phase and microstructure. Meanwhile, wear and anti-resistance ability were detected. The results showed that Nb, NbC, ε-martensite, α’-martensite and γ-austenite were found in SMA/Nb coating. The microhardness was enhanced because of the solid solution strengthening and second phase strengthening. Also, the shape recovery rate and anti-corrosion property of the SMA/Nb coating are improved as well.

Similar content being viewed by others

References

D. Li et al., Enhancement of wear resistance by sand blasting-assisted rapid plasma nitriding for 304 austenitic stainless steel, Surf. Eng., 36 (2020) 524–530.

N. G. Krishna et al., Surface modification of type 304 stainless steel with duplex coatings for corrosion resistance in sea water environments, Surf. Eng., 31 (2015) 39–47.

L. J. Song et al., Repair of 304 stainless steel by laser cladding with 316L stainless steel powders followed by laser surface alloying with WC powders, J. Manuf. Process., 24 (2016) 116–124.

S. T. Sun et al., Effect of CeO2 addition on microstructure and mechanical properties of in-situ (Ti, Nb) C/Ni coating, Surf. Coat. Tech., 359 (2019) 300–313.

G. Muvvala et al., In-process detection of microstructural changes in laser cladding of in-situ Inconel 718/TiC metal substrate composite coating, J. Alloy. Compd., 740 (2018) 545–558.

L. Lucia et al., On the influence of laser cladding parameters and number of deposited layers on as-built and machined AISI H13 tool steel multilayered claddings, CIRP. J. Manuf. Sci. Tec., 35 (2021) 361–370.

Tamanna et al., A numerical investigation of similar and dissimilar clad materials on H13 steel substrate in the laser cladding process, Adv. Mater. Process. Tec., 5 (2019) 598–606.

M. S. Ghorashi et al., Considering cyclic plasticity to predict residual stresses in laser cladding of Inconel 718 multi bead samples, J. Manuf. Process., 42 (2019) 149–158.

D. Z. Wang et al., Residual stress and cracking behaviors of Cr13Ni5Si2 based composite coatings prepared by laser-induction hybrid cladding, Surf. Coat. Tech., 274 (2015) 51–59.

Y. F. Tao et al., Residual stress distribution in different depths of TiNi/Ti2 Ni-based laser clad coating prepared at different environmental temperatures, T. Nonferr. Metal. Soc., 27 (2017) 2043–2054.

H. Ali et al., Residual stress development in selective laser-melted Ti6Al4V: a parametric thermal modelling approach, Int. J. Adv. Manuf. Tech., 97 (2018) 2621–2633.

W. Ya et al., Cladding of Tribaloy T400 on steel substrates using a high power Nd: YAG laser, Surf. Coat. Tech., 350 (2018) 323–333.

C. Courbon et al., Near surface transformations of stainless steel cold spray and laser cladding deposits after turning and ball-burnishing, Surf. Coat. Tech., 371 (2019) 235–244.

J. S. Robinson et al., Residual stress relief in the aluminium alloy 7075, Mater. Sci. Tech-Lond., 33 (2017) 1765–1775.

C. Bellini et al., A cyclic integrated microstructural-mechanical model for a shape memory alloy, Int. J. Fatigue., 153 (2021) 106473.

P. Xu et al., In-situ synthesis of Fe-Mn-Si-Cr-Ni shape memory alloy functional coating by laser cladding, Chin. Opt. Lett., 12 (2014) 52–54.

T. Maki, Microstructure, mechanical property and shape memory effect or ferrous martensite, Shanghai Mentals., 15 (1993) 1–7.

S. Morito et al., The morphology and crystallography of lath martensite in Fe-C alloys, Acta. Mater., 51 (2003) 1789–1799.

W. Q. Li et al., Microstructure evolution and mechanical properties of 308L stainless steel coatings fabricated by laser hot wire cladding, Mat. Sci. Eng. A-Struct., 824 (2021) 141825.

Z. H. Tian et al., Microstructure and properties of Inconel 625 + WC composite coatings prepared by laser cladding, Rare Metals., 40 (2021) 2281–2291.

B. Zhang et al., Laser surface alloying with carbon on 15-5PH steel for improved wear resistance, Surf. Eng., 37 (2021) 669–677.

X. L. Ping, Microstructure and performance of Nb-bearing Ni60A-Cr3C2 coatings manufactured by laser cladding, Surf. Eng., 36 (2020) 1294–1306.

J. B. Cheng et al., Nb doping in laser-cladded Fe25Co25Ni25 (B0.7Si0.3)25 high entropy alloy coatings: microstructure evolution and wear behavior, Surf. Coat. Tech., 402 (2020) 126321.

Y. X. Guo and Q. B. Liu, MoFeCrTiWAlNb refractory high-entropy alloy coating fabricated by rectangular-spot laser cladding, Intermetallics., 102 (2018) 78–87.

W. Xu et al., Microstructure, wear resistance, and corrosion performance of Ti35Zr28Nb alloy fabricated by powder metallurgy for orthopedic applications, J. Mater. Sci. Technol., 41 (2020) 191–198.

S. Guo et al., Wear response of metastable β-type Ti-25Nb-2Mo-4Sn alloy for biomedical applications, Rare Metals., 34 (2015) 564–568.

J. Z. Shao et al., Microstructure and wear behaviors of TiB/TiC reinforced Ti2Ni/α (Ti) matrix coating produced by laser cladding, Rare Metals., 39 (2020) 304–315.

Y. G. Meng et al., A review of recent advances in tribology, Friction, 8 (2020) 221–300.

H. Z. Wang et al., Microstructure and properties of laser clad Fe-based amorphous alloy coatings containing Nb powder, J. Non-cryst. Solids., 550 (2020) 120351.

S. C. Tao et al., Microstructure, mechanical properties and antibacterial properties of the microwave sintered porous Ti-3Cu alloys, J. Alloy. Compd., 812 (2019) 152142.

W.R. Wang et al., Microstructure and corrosion behavior of (CoCrFeNi)95Nb5 high-entropy alloy coating fabricated by plasma spraying, Materials., 12 (2019) 694–706.

X. Shi et al., Corrosion resistance and biocompatibility of calcium-containing coatings developed in near-neutral solutions containing phytic acid and phosphoric acid on AZ31B alloy, J. Alloy. Compd., 823 (2020) 153721.

X. He et al., Microstructure and corrosion behaviours of composite coatings on S355 offshore steel prepared by laser cladding combined with micro-arc oxidation, Appl. Surf. Sci., 497 (2019) 143703.

U. K. Mudali and B. Raj, High Nitrogen Steels and Stainless Steels: Manufacturing, Properties and Applications, Asm. International (2004) 148.

Z. Z. Dong et al., Effect of pre-deformation at room temperature on shape memory properties of stainless type Fe-15Mn-5Si-9Cr-5Ni-(0.5–1.5) NbC alloys, Acta. Mater., 53 (2005) 4009–4018.

Acknowledgments

This study was funded by SRT Project of Guizhou University ([2021]003), Guizhou Provincial Science and Technology Foundation (QKHJC ZK [2021] general 241), Guizhou Provincial Science and Technology Achievements Transformation Project (QKHCG [2021] general 112), Natural Science Research Project of Guizhou Provincial Education Department (QJH KY Z [2021]098) and Fostering Projects of Guizhou University ([2020]66).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Xiaochen Liu is an undergraduate student at Guizhou University and his major is Materials Science and Engineering. He joined Prof. Xu’s group in 2020. His current research interest focuses on Shape Memory Alloy.

Peng Xu received his Ph.D. in Dalian Maritime University. He is currently an Associate Professor in the college of materials and metallurgy, Guizhou university. His research interest mainly focuses on Shape memory alloy, Additive manu- facturing, Lithium sulfur battery.

Like Yao is an undergraduate student majoring in Materials Science and Engineering at Guizhou University. He joined Prof. Xu’s group in his sophomore year. His research direction is laser cladding and metal heat treatment.

Pang Chi was born in 1975 and received his Master’s degree in Xidian University. He is an Associate Professor in the College of Materials and Metallurgy, Guizhou University. His research subjects are Additive manufacturing and ZnO piezoelectric ceramics.

Xiang Li is a junior student at Guizhou University, majoring in Materials Science and Engineering. He joined Prof. Xu’s group in his sophomore year and his research directions focus on Surface Modification and Shape Memory Alloy.

Rights and permissions

About this article

Cite this article

Liu, X., Xu, P., Yao, L. et al. Nb reinforced Fe-Mn-Si shape memory alloy composite coating fabricated by laser cladding on 304 stainless steel surface. J Mech Sci Technol 36, 5027–5033 (2022). https://doi.org/10.1007/s12206-022-0915-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0915-y