Abstract

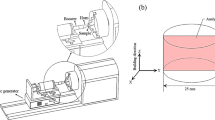

This study investigated the effect of ultrasonic nanocrystal surface modification (UNSM) on the deteriorated surface of AISI 316L deposited using the direct energy deposition (DED) technology. After UNSM treatment, the coarse DEDed surface was fined, and a regular micro-surface profile was implemented. Compared to the case before UNSM treatment, the waviness and roughness of the surface after UNSM treatment decreased by up to 73.8 % and 86.2 %, respectively, and reduced further as the UNSM interval was decreased. Surface severe plastic deformation (S2PD) was induced in the dendrite structure of the UNSM-treated DEDed sample surface. The microstructure was deformed till a depth of up to 92.13 mm from the surface and was significantly affected by the interval. After UNSM treatment, the hardness improved by up to 71.5 % and gradually decreased from the surface to the inside; the hardness was improved by UNSM up to a maximum depth of 400 μm. Although the UNSM interval condition had a significant effect on the DEDed surface, it barely affected the relationship between the directions of DED deposition and UNSM treatment. This study confirmed that the UNSM technology can effectively improve a DEDed surface.

Similar content being viewed by others

References

E. Yasa and J. P. Kruth, Application of laser re-melting on selective laser melting parts, Advances in Production Engi neering and Management, 6 (4) (2011) 259–270.

J. Mazumder, D. Dutta, N. Kikuchi and A. Ghosh, Closed loop direct metal deposition; art to part, Optic and Laser in Engineering, 34 (4) (2000) 397–414.

A. J. Pinkerton and L. Li, The effect of laser pulse width on multiple-layer 316L steel clad microstructure and surface finish, Applied Surface Science, 208–209 (2003) 405–410.

M. Gharbi, P. Peyrea, C. Gorny, M. Carin, S. Morville, P. Le Masson, D. Carron and R. Fabbro, Influence of various process conditions on surface finishes induced by the direct metal deposition laser technique on a Ti-6Al-4V alloy, Journal of Materials Processing Technology, 213 (2013) 791–800.

G. Zhu, D. Li, A. Zhang, G. Pi and Y. Tang, The influence of laser and powder defocusing characteristics on the surface quality in laser direct metal deposition, Optics and Laser Technology, 44 (2012) 349–356.

M. Alimardani, V. Fallah, M. Iravani-Tabrizipour and A. Khajepour, Surface finish in laser solid freeform fabrication of an AISI 303L stainless steel thin wall, Journal of Materials Processing Technology, 212 (2012) 113–119.

Y. Gong and P Li, Analysis of tool wear performance and surface quality in post milling of additive manufactured 316L stainless steel, Journal of Mechanical Science and Technology, 33 (5) (2019) 2387–2395.

P. K. Farayibi, T. E. Abioye, J. W. Murray, P. K. Kinnell and A. T. Clare, Surface improvement of laser clad Ti-6Al-4V using plain waterjet and pulsed electron beam irradiation, Journal of Materials Processing Technology, 218 (2015) 1–11.

K. Y. Luo, X. Jing, J. Sheng, G. F. Sun, Z. Yan and J. Z. Lu, Characterization and analyses on micro-hardness, residual stress and microstructure in laser cladding coating of 316L stainless steel subjected to massive LSP treatment, Journal of Alloys and Compounds, 673 (2016) 158–169.

A. Cherif, Y. Pyoun and B. Scholtes, Effects of ultrasonic nanocrystal surface modification (UNSM) on residual stress state and fatigue strength of AISI 304, Journal of Materials Engineering and Performance, 19 (2) (2010) 282–286.

X. J. Cao, Y. S. Pyoun and R. Murakami, Fatigue proper ties of a S45C steel subjected to ultrasonic nanocrystal sur face modification, Applied Surface Science, 256 (2010) 6297–6303.

D. Gu, Laser Additive Manufacturing of High-Performance Materials, 1st Ed., Springer-Verlag Berlin Heidelberg, New York, USA (2015).

A. Amanov, Y. S. Pyun and S. Sasaki, Effects of ultrasonic nanocrystalline surface modification (UNSM) technique on the tribological behavior of sintered Cu-based alloy, Tribology International, 72 (2014) 187–197.

A. Amanov, I. S. Cho, Y. S. Pyoun, C. S. Lee and I. G. Park, Micro-dimpled surface by ultrasonic nanocrystal sur-face modification and its tribological effects, Wear, 286–287 (2012) 136–144.

A. Amanov, Y. S. Pyoun, I. S. Cho, C. S. Lee and I. G. Park, The evaluation of the micro-tracks and micro-dimples on the tribological characteristics of thrust ball bearings, Journal of Nanoscience and Nanotechnology, 11 (2011) 701–705.

B. Zheng, Y. Zhou, J. E. Smugeresky, J. M. Schoenung and E. J. Lavernia, Thermal behavior and microstructure evolution during laser deposition with laser-engineered net shaping: part II. Experimental investigation and discussion, Metallurgical and Materials Transactions A, 39 (2008) 2237–2245.

M. Umemoto, Nanocrystallization of steels by severe plas-tic deformation, Materials Transactions, 44 (10) (2003) 1900–1911.

J. H. Moon, S. M. Baek, S. G. Lee, Y. J. Seong, A. Amanov, S. H. Lee and H. S. Kim, Effects of residual stress on the mechanical properties of copper processed using ultrasonic-nanocrystalline surface modification, Materials Research Letters, 7 (3) (2019) 97–102.

B. Wu, P. Wang, Y. S. Pyoun, J. Zhang and R. Murakami, Study on the fatigue properties of plasma nitriding S45C with a pre-ultrasonic nanocrystal surface modification process, Surface and Coatings Technology, 216 (2013) 191–198.

C. Ye, A. Telang, A. S. Gill, S. Suslov, Y. Idell, K. Zweiacker, J. M. K. Wiezorek, Z. Zhou, D. Qian, S. Ramaiah Mannava and V. K. Vasudevan, Gradient nanostructure and residual stresses induced by ultrasonic nano-crystal surface modification in 304 austenitic stainless steel for high strength and high ductility, Materials Science and Engineering: A, 613 (2014) 274–288.

Z. C. Cordero, B. E. Knight and C. A. Schuh, Six decades of the Hall-Petch effect—A survey of grain-size strengthening studies on pure metals, International Materials Reviews, 61 (2016) 495–512.

Acknowledgments

This study was supported by the Ministry of Trade, Industry and Energy (MOTIE) and the Korea Institute for Advancement of Technology (KIAT) through the European International R&D Collaboration (G02P03040000701), Republic of Korea. Additional support by the Korea Maritime and Ocean University Research Fund is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This paper was presented at ICMDT 2019, Shiroyama Hotel, Kagoshima, Japan, April 24-27, 2019. Recommended by Guest Editor Haedo Jeong.

Min-Seob Kim is a currently a M.S. student at the Department of Ocean Advanced Materials Convergence Engi-neering, Korea Maritime and Ocean University, Korea. He received his bachelor’s degree at Korea Maritime and Ocean University, Korea in 2018.

Yeong-Kwan Jo is a Ph.D. course student at the School of Mechanical Engineering in Pusan National University. His research topic interests are development of cladding process and its application to surface mechanical characteristics.

Sang Hu Park is a Professor in the School of Mechanical Engineering at Pusan National University. He earned his M.A. and Ph.D. in mechanical engi-neering at Korea Advanced Institute of Science and Technology (KAIST, Korea) in 1996 and 2006, respectively. His research fields are the development of 3D printing process, mechanical design, and manufacturing technology, especially for multi-scale structures.

Do-Sik Shim received Ph.D. in Mechanical Engineering from KAIST, Korea in 2010. He has been an Assistant Professor at Korea Maritime and Ocean University (KMOU) since 2017. His research interests include incremental and roll forming for sheet metal, direct energy deposition (DED) and structural analysis as well as optimal design.

Rights and permissions

About this article

Cite this article

Kim, MS., Jo, YK., Park, SH. et al. Application of ultrasonic nanocrystal surface modification for improving surface profile of DEDed AISI 316L. J Mech Sci Technol 33, 5659–5667 (2019). https://doi.org/10.1007/s12206-019-1108-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1108-1