Abstract

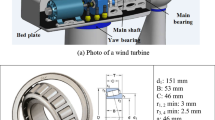

A rotational connection between two substructures generally consists of a slewing bearing which is very often used for heavy loads at low speeds. Slewing bearing condition monitoring is a good method to identify the inception and propagation of structural defects at an early stage for timely remedy, and ultimately, enable condition-based “intelligent” maintenance instead of schedule-based. The traditional health evaluation accuracy is not high based on single vibrating signal. We present a new strategy for health evaluation of slewing bearing based on multiple characteristic parameters and the artificial neural networks, and we applied the genetic algorithm to model multiparameters health evaluation. Seventy days fatigue life test was carried out using a special slewing bearing test table and 70 sets data was chosen to input the networks evaluation model for training and evaluation. Test results show that the ANN (Artificial neural network) with GA (Genetic algorithm) optimization converges more easily, takes fewer iterations and shorter training time, and has higher precision and good stability. And the output of multi-parameters health evaluation network model shows a better agreement with the target. The evaluation results were in accordance with the experiment. Therefore, this methodology can be used to evaluate the health state of slewing bearing.

Similar content being viewed by others

References

S. Zupan and I. Prebil, Carrying angle and carrying capacity of a large single row ball bearing as a function of geometry parameters of the rolling contact and the supporting structure stiffness, Mechanism and Machine Theory, 36(10) (2001) 1087–1103.

Jose Ignacio Amasorrain, Xabier Sagartzazu and Jorge Damian, Load distribution in a four contact-point slewing bearing, Mechanism and Machine Theory, 38(6) (2003) 479–496.

Robert Kunc and Ivan Prebil, Numerical determination of carrying of large rolling bearings, Journal of Materials Processing Technology, 155–156 (2004) 1696–1703.

Robert Kunc, Andrej Zerovnik and Ivan Prebil, Verification of numerical determination of carrying capacity of large rolling bearings with hardened raceway, International Journal of Fatigue, 29 (2007) 1913–1919.

Alain Daidie, Zouhair Chaib and Antoine Ghosn, 3D simplified finite elements analysis of load and contact angle in a slewing ball bearing, Journal of Mechanical Design, 130 (2008) 1–8.

Ludwik Kania, Modelling of rollers in calculation of slewing bearing with the use of finite elements, Mechanism and Machine Theory, 41 (2006) 1359–1376.

Xuehai Gao, Xiaodiao Huang and Hua Wang, Effect of raceway geometry parameters on the carrying capability and the service life of a four-point-contact slewing bearing, Journal of Mechanical Science and Technology, 24(10) (2010) 2083–2089.

Potocnik, Rok; Goencz, Peter; Glodez, Srecko, Static capacity of a large double row slewing ball bearing with predefined irregular geometry, Mechanism and Machine Theory, 64(1) (2013) 67–79.

L. M. Rodger, The application of vibration signature analysis and acoustic emission source location to on-line condition monitoring of anti-friction bearings, Tribology International, April (1979) 51–59.

Z. J. Liu and J. Chen, Monitoring and diagnosis technique on slewing bearing, Advanced Material Research, 156–157 (2011) 1478–1483.

M. Žvokelj, S. Zupan and I. Prebil, Multivariate and multiscale monitoring of large-size low-speed bearings using ensemble empirical mode decomposition method combined with principal component analysis, Mechanical Systems and Signal Processing, 24 (2010) 1049–1067.

M. Žvokelj, S. Zupan and I. Prebil, Non-linear multivariate and multiscale monitoring and signal denoising strategy using kernel principal component analysis combined with ensemble empirical mode decomposition method, Mechanical Systems and Signal Processing, 25 (2011) 2631–2653.

Wahyu Caesarendra, Prabuono Buyung Kosasih, Anh Kiet Tieu, Craig Alexander Simpson Moodie and Byeong-Keun Choi, Condition monitoring of naturally damaged slow speed slewing bearing based on ensemble empirical mode decomposition, Journal of Mechanical Science and Technology, 27(8) (2013) 2253–2262.

Yixi Ye and Hanbin Xiao, Extraction of vibration signal of large-scale bearing based on wavelet analysis, Journal of Wuhan University of Technology, 28(6) (2008) 840–843.

Qunxie Jun, Zhijun Liu and Huabiao Li, Vibration and diagnosis application technology research of large rotating bearing, Noise and Vibration Control, 23(4) (2003) 39–42.

Xingdong Wang, Yuanjun Liu and Aijun Yan, Predication methods of residual service lifetime for slewing bearing mounted in ladle turret, Journal of Hubei University of Technology (3) (2006) 34–36.

Zeki Klral and Hira Karagulle, Vibration analysis of rolling element bearings with various defects under the action of an unbalanced force, Mechanical Systems and Signal Processing, 20 (2006) 1967–1991.

S. F. Ding, Y. N. Zhang and J. R. Chen, Research on using genetic algorithms to optimize Elman neural networks, Neural Computing and Applications (2012) 1–5.

G. Liu, X. C. Wang and F. W. Li, Fault diagnosis of diesel engine fuel system based on genetic algorithm optimizing BP neural network model and D-S evidence theory, ICIC Express Letters, Part B:Applications, 3(4) (2013) 707–716.

E. P. Zhang, H. F. Zhang and B. C. Xue, Study of method on genetic BP networks for vibration fault diagnosis of turbo generator, Intelligent System and Applied Material, 466–467 (2012) 1025–1030.

A. Sedki, D. Ouazar and E. EI Mazoudi, Evolving neural network using real coded genetic algorithm for daily rainfallrunoff forecasting, Expert Systems with Applications, 36 (2009) 4523–4527.

Rajendra Prasad, A. Pandey, K. P. Singh, V. P. Singh, R. K. Mishra and D. Singh, Retrieval of spinach crop parameters by microwave remote sensing with back propagation artificial neural networks: A comparison of different transfer functions, Advances in Space Research, 50 (2012) 363–370.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Yeon June Kang

Hua Wang received his Ph.D. from Harbin Engineering University, China, in 2006. He is currently an associate professor at the Nanjing University of Technology. His research interests are in the areas of mechanical manufacturing and automation, measurement, life prediction and intelligent life-prolonging method.

Mingmin Tang received his B.S. from Nanjing University of Technology, China, in 2011. He is currently working towards his M.S. in the School of Mechanical and Power Engineering, Nanjing University of Technology. His current research interests are on condition monitoring of the huge bearings.

Xiaodiao Huang received his M.S. from Harbin Engineering University, China, in 1987. He is currently a Professor at the Nanjing University of Technology. His research interests are in the areas of mechanical manufacturing and automation, NC technology, and technology on huge bearings and gears.

Rights and permissions

About this article

Cite this article

Wang, H., Tang, M. & Huang, X. Smart health evaluation of slewing bearing based on multiple-characteristic parameters. J Mech Sci Technol 28, 2089–2097 (2014). https://doi.org/10.1007/s12206-014-0405-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0405-y