Abstract

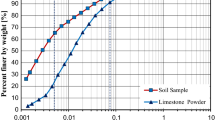

Civil engineering infrastructure like roads, bridges, railway tracks, and building structures constructed on fat clay becomes suspicious due to adverse change in the behavior of such soil on interaction with water. To solve such problems especially in underdeveloped countries, application of industrial waste like glass is associated with technical, financial, and environmental benefits. Emphasis of current study is to determine the consequences of powdered glass (GC) on mechanical behavior of fat clay. A fat clayey sample was collected from location of Nandipur, and glass was taken from local glass market in powdered form. Samples were remolded at optimum moisture content and maximum dry unit weight by mixing GC up to 14%. Soil classification tests, modified compaction tests, unconfined compression tests, one-dimensional consolidation tests, California bearing ratio (CBR) tests, and scanning electron microscope were performed. With increasing GC, the consistency limits, compression characteristics, swell characteristics, and optimum moisture content decreased while maximum dry unit weight, yield stress, CBR, and unconfined compression strength increased. Influence of GC is also observed on microstructure of treated clay. After 12% GC, aforementioned geotechnical characteristics behave inversely for selected clay. The optimum GC-value for the tested clay is about 12%, however, this value may vary from clay to clay.

Similar content being viewed by others

Abbreviations

- ASTM:

-

American society for testing and materials

- C :

-

Constant of σy-qu relationship

- CBR(S):

-

Soaked California bearing ratio

- C c :

-

Compression index

- C s :

-

Swell index

- e :

-

Void ratio

- e 0 :

-

Initial void ratio

- E 50 :

-

Deformation modulus

- GC:

-

Powdered glass content

- G s :

-

Specific gravity

- GSD:

-

Grain size distribution

- I P :

-

Plasticity index

- m c1ay :

-

Dry mass of clay

- m PG :

-

Dry mass of powdered glass

- q u :

-

Unconfined compressive strength

- SEM:

-

Scanning electron microscope

- USCS:

-

Unified soil classification system

- w L :

-

Liquid limit

- w n :

-

Natural moisture content

- w opt :

-

Optimum moisture content

- w p :

-

Plastic limit

- γ d :

-

Dry unit weight

- γ dmcx :

-

Maximum dry unit weight

- ε α :

-

Axial strain

- η :

-

Dimensionless parameter of E50-qu relationship

- σ v ′ :

-

Effective vertical stress

- σ y :

-

Yield stress

References

ASTM D1557 (2012) Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). ASTM D1557, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D1557-12E01

ASTM D1883 (2016) Standard test method for california bearing ratio (CBR) of laboratory-compacted soils. ASTM D1883, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D1883-16

ASTM D2166 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM D2166, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D2166D2166M-16

ASTM D2435 (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. ASTM D2435, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D2435_D2435M-11

ASTM D2487 (2017) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). ASTM D2487, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D2487-17E01

ASTM D4318 (2017) Standard test methods for liquid limit, plastic limit and plasticity index of soils. ASTM D4318, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D4318-17E01

ASTM D7928 (2017) Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. ASTM D7928, ASTM International, West Conshohocken, PA, USA, DOI: https://doi.org/10.1520/D7928-17

Damian G, Lanzerstorfer C, Damian F, Iepure G (2018) Distribution of heavy metals and minerals in the various size fractions of soil from Copşa Mică, România. Water Air & Soil Pollution 229(6):202, DOI: https://doi.org/10.1007/s11270-018-3862-6

Day RW (2006) Foundation engineering handbook: Design and construction with the 2006 international building code. McGraw Hill, Singapore

Disfani M, Arulrajah A, Bo M, Sivakugan N (2012) Environmental risks of using recycled crushed glass in road applications. Journal of Cleaner Production 20(1):170–179, DOI: https://doi.org/10.1016/j.jclepro.2011.07.020

Fauzi A, Djauhari Z, Fauzi UJ (2016) Soil engineering properties improvement by utilization of cut waste plastic and crushed waste glass as additive. International Journal of Engineering and Technology 8(1):15, DOI: https://doi.org/10.7763/IJET.2016.V8.85

Fauzi A, Fauzi UJ, Nazmi WM (2013) Engineering quality improvement of Kuantan clay subgrade using recycling and reused materials as stabilizer. Procedia Engineering 54:675–689, DOI: https://doi.org/10.1016/j.proeng.2013.03.062

Horpibulsuk S, Rachan R, Chinkulkijniwat A, Raksachon Y, Suddeepong A (2010) Analysis of strength development in cement-stabilized silly clay from microstructural considerations. Construction and Building Materials 24(10):2011–2021, DOI: https://doi.org/10.1016/j.conbuildmat.2010.03.011

Hu K, Chen X, Chen J, Ren X (2018) Laboratory investigation of the effect of nano-silica on unconfined compressive strength and frost heaving characteristics of silty clay. Soil Mechanics and Foundation Engineering 55(5), DOI: https://doi.org/10.1007/s11204-018-9548-7

HUD (1971) Expansive soil identification and classification. Region IX, HUD and FHA Regulations, United States Department of Housing and Urban Development, Washington DC, USA

Imtiaz R (2015) Characterization and mapping of expansive soils of punjab. PhD Thesis, Civil Engineering Department, University of Engineering and Technology, Lahore, Pakistan

Jain A, Choudhary AK, Jha J (2019) Influence of rice husk ash on the swelling and strength characteristics of expansive soil. Geotechnical and Geological Engineering 38:2293–2302, DOI: https://doi.org/10.1007/s10706-019-01087-6

Khalid U, Liao C, Ye G-L, Yadav SK (2018) Sustainable improvement of soft marine clay using low cement content: A multi-scale experimental investigation. Construction and Building Materials 191:469–480, DOI: https://doi.org/10.1016/j.conbuildmat.2018.10.034

Ling TC, Poon CS, Wong HW (2013) Management and recycling of waste glass in concrete products: Current situation in Hong Kong. Resources Conservation and Recycling 70:25–31, DOI: https://doi.org/10.1016/j.resconrec.2012.10.006

Mathew A, Raneesh KY (2016) Effect on strength characteristics of expansive soil using Sisal fibre and waste materials. International Journal of Environmental Science and Research 5(9):1702–1707

Mokhtari M, Dehghani M (2012) Swell-shrink behavior of expansive soils, damage and control. Electronic Journal of Geotechnical Engineering (EJGE) 17:2673–2682

Mowafy YM, Bauer GE, Sakeb FH (1985) Treatment of expansive soils: A laboratory study. Transportation Research Record 1032:34–39

Mujtaba H, Aziz T, Farooq K (2018) Improvement in engineering properties of expansive soils using ground granulated blast furnace slag. Journal of the Geological Society of India 92:357–362, DOI: https://doi.org/10.1007/s12594-018-1019-2

Nawaz M, Aziz M, Israr J (2019) Orientation of deposition planes and shear strength of typical clays from Pakistan. Iranian Journal of Science and Technology, Transactions of Civil Engineering 44:931–939, DOI: https://doi.org/10.1007/s40996-019-00267-x

Olufowobi J, Ogundoju A, Michael B, Aderinlewo O (2014) Clay soil stabilisation using powdered glass. Journal of Engineering Science and Technology 9(5):541–558

Pakistan Environmental Protection Agency (2005) Guideline for solid waste management. Pakistan Environmental Protection Agency, Islamabad, Pakistan

Puppala AJ, Pedarla A (2017) Innovative ground improvement techniques for expansive soils. Innovative Infrastructure Solution 2(1):24, DOI: https://doi.org/10.1007/s41062-017-0079-2

Sabat AK, Pat, S (2014) A review of literature on stabilization of expansive soil using solid wastes. Electronic Journal of Geotechnical Engineering 19:6251–6267, DOI: https://doi.org/10.4236/eng.2017.912060

Singh M, Trivedi A, Shukla SK (2019) Strength enhancement of the subgrade soil of unpaved road with geosynthetic reinforcement layers. Transportation Geotechnics 19:54–60, DOI: https://doi.org/10.1016/j.trgeo.2019.01.007

Sylvestre O, Bilodeau J-P, Doré G (2019) Effect of frost heave on long-term roughness deterioration of flexible pavement structures. International Journal of Pavement Engineering 20(6):704–713, DOI: https://doi.org/10.1080/10298436.2017.1326598

Tiwari A, Mahiyar H (2014) Experimental study on stabilization of black cotton soil by fly ash, coconut coir fiber & crushed glass. International Journal of Emerging Technology and Advanced Engineering 4(11):330–333

Topcu I, Canbaz M (2004) Properties of concrete containing waste glass. Cement and Concrete Research 34(2):267–274, DOI: https://doi.org/10.1016/j.cemconres.2003.07.003

Wang DX, Abriak NE, Zentar R Xu W (2012) Solidification/stabilization of dredged marine sediments for road construction. Environmental Technology 33(1):95–101, DOI: https://doi.org/10.1080/09593330.2011.551840

Yin J, Lai C (1998) Strength and stiffness of Hong Kong marine deposits mixed with cement. Geotechnical Engineering 29(1)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mujtaba, H., Khalid, U., Farooq, K. et al. Sustainable Utilization of Powdered Glass to Improve the Mechanical Behavior of Fat Clay. KSCE J Civ Eng 24, 3628–3639 (2020). https://doi.org/10.1007/s12205-020-0159-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-0159-2