Abstract

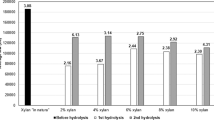

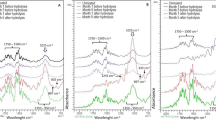

A large volume of biomass residue is disposed daily, and the use of chemical and enzymatic treatments is an alternative to reuse it generating value-added products such as xylooligosaccharides (XOS). Banana peel, guava bagasse, orange bagasse, and restaurant pre-prepare waste were subjected to three treatments for xylan solubilization. Subsequently, xylan was enzymatically hydrolyzed to obtain xylooligosaccharides. The maximum polysaccharide solubilization using alkaline hydrogen peroxide was 90.70% from restaurant residue. Sodium hydroxide solubilized 88.01% of xylan from guava bagasse and 74.20% of xylan from the banana peel, using potassium hydroxide. After enzymatic hydrolysis, the maximum production of XOS was 54.14% with banana peel residue (peroxide solubilized), 59.86% with guava bagasse (sodium hydroxide solubilized), 50.42% for orange bagasse (peroxide solubilized), and 50.80% with restaurant residue (potassium hydroxide solubilized). The results showed that each of the biomass had a different condition of treatment. The best conditions to obtain xylan from banana peel and guava bagasse were using NaOH treatment, and from orange bagasse and restaurant pre-prepare were using KOH. To produce XOS, banana peel and orange bagasse were treated with peroxide, and the guava bagasse and restaurant residue were treated with potassium hydroxide and subsequently submitted to enzymatic hydrolysis for 12 and 48 h.

Similar content being viewed by others

References

Melati RB, Shimizu FL, Oliveira G et al (2019) Key factors affecting the recalcitrance and conversion process of biomass. Bioenergy Res 12:1–20. https://doi.org/10.1007/s12155-018-9941-0

Brienzo M, Carvalho AFA, de Figueiredo FC, de Oliva-Neto P (2016) Sugarcane bagasse hemicellulose properties, extraction technologies and xylooligosaccharides production. In: Riley GL (ed) Food Waste. pp 155–188

Gírio FM, Fonseca C, Carvalheiro F et al (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101(13):4775–4800. https://doi.org/10.1016/j.biortech.2010.01.088

Madeira JV, Contesini FJ, Calzado F, et al (2017) Agro-industrial residues and microbial enzymes: an overview on the eco-friendly bioconversion into high value-added products. In: Biotechnology of Microbial Enzymes: Production, Biocatalysis and Industrial Applications. Elsevier Inc., pp 475–511

Álvarez C, González A, Negro MJ et al (2017) Optimized use of hemicellulose within a biorefinery for processing high value-added xylooligosaccharides. Ind Crop Prod 99:41–48. https://doi.org/10.1016/j.indcrop.2017.01.034

Alves RC, Melati RB, Casagrande GM et al (2021) Sieving process selects sugarcane bagasse with lower recalcitrance to xylan solubilization. J Chem Technol 96:327–334. https://doi.org/10.1002/JCTB.6541

Fernandes ÉS, Bueno D, Pagnocca FC, Brienzo M (2020) Minor Biomass Particle Size for an Efficient Cellulose Accessibility and Enzymatic Hydrolysis. ChemistrySelect 5:7627–7631. https://doi.org/10.1002/SLCT.202001008

Forsan CF, de Freitas C, Masarin F, Brienzo M (2021) Xylooligosaccharide production from sugarcane bagasse and leaf using Aspergillus versicolor endoxylanase and diluted acid. Biomass Convers. https://doi.org/10.1007/s13399-021-01403-2

Abe MM, Branciforti MC, Brienzo M (2021) Biodegradation of hemicellulose-cellulose-starch-based bioplastics and microbial polyesters. Recycling 6. https://doi.org/10.3390/RECYCLING6010022

de Freitas C, Carmona E, Brienzo M (2019) Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact Carbohyd Diet Fibre 18:100184. https://doi.org/10.1016/J.BCDF.2019.100184

de Freitas C, Terrone CC, Masarin F et al (2021) In vitro study of the effect of xylooligosaccharides obtained from banana pseudostem xylan by enzymatic hydrolysis on probiotic bacteria. Biocatal Agric Biotechnol 33:101973. https://doi.org/10.1016/J.BCAB.2021.101973

Aachary AA, Prapulla SG (2011) Xylooligosaccharides (XOS) as an emerging prebiotic: microbial synthesis, utilization, structural characterization, bioactive properties, and applications. Compr Rev Food Sci Food Saf 10:2–16. https://doi.org/10.1111/j.1541-4337.2010.00135.x

Qing Q, Li H, Kumar R, Wyman CE (2013) Xylooligosaccharides production, quantification, and characterization in context of lignocellulosic biomass pretreatment. In: Wyman CE (ed) Aqueous pretreatment of plant biomass for biological chemical conversion to fuels and chemicals. Wiley Blackwell, Oxford

Akpinar O, Erdogan K, Bakir U, Yilmaz L (2010) Comparison of acid and enzymatic hydrolysis of tobacco stalk xylan for preparation of xylooligosaccharides. LWT-Food Sci Technol 43:119–125. https://doi.org/10.1016/j.lwt.2009.06.025

Pereira BS, Castrisana RN, de Freitas C et al (2021) Chemical composition determines the bioenergy potential of food waste from pre- and post-production. J Mater Cycles Waste Manag 23(4 23):1365–1373. https://doi.org/10.1007/S10163-021-01215-6

Brienzo M, Siqueira AF, Milagres AMF (2009) Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem Eng J 46:199–204. https://doi.org/10.1016/j.bej.2009.05.012

Martins RP, Schmatz AA, de Freita LA et al (2021) Solubilization of hemicellulose and fermentable sugars from bagasse, stalks, and leaves of sweet sorghum. Ind Crop Prod 170:113813. https://doi.org/10.1016/J.INDCROP.2021.113813

Cano Carmona E, Brochette-Braga MR, Aparecida Pizzirani-Kleiner A, Jorge A (1998) Purification and biochemical characterization of an endoxylanase from Aspergillus versicolor. FEMS Microbiol Lett 166:311–315. https://doi.org/10.1111/j.1574-6968.1998.tb13906.x

Gondim JAM, Moura MDFV, Dantas AS et al (2005) Centesimal composition and minerals in peels of fruits. Food Sci Technol 25:825–827

Silva NCR (2014) Using banana peels as biosorbent for the adsorption of lead (II) in aqueous solution. 2014 45 f. Completion of course work (Bachelor of Environmental Engineering) - Federal Technological University of Paraná. Campo Mourão, 2014

Orozco RS, Hernández PB, Morales GR et al (2014) Characterization of lignocellulosic fruit waste as an alternative feedstock for bioethanol production. Bioresources 9:1873–1885

Mantovan J, Giraldo GAG, Marin BM, Kishima JOF, Mali S (2020) Valorization of orange bagasse through one-step physical and chemical combined processes to obtain a cellulose-rich material. Sci Food Agric 101:2362–2370. https://doi.org/10.1002/jsfa.10859

Bragatto J, Segato F, Squina FM (2013) Production of xylooligosaccharides (XOS) from delignified sugarcane bagasse by peroxide-HAc process using recombinant xylanase from Bacillus subtilis. Ind Crop Prod 51:123–129. https://doi.org/10.1016/j.indcrop.2013.08.062

Teixeira LC, Linden JC, Schroeder HA (2000) Simultaneous Saccharification and Cofermentation of Peracetic Acid-Pretreated Biomass. Appl Biochem Biotechnol 84–86:111–128. https://doi.org/10.1385/abab:84-86:1-9:111

Monte JR, Brienzo M, Milagres AMF (2011) Utilization of pineapple stem juice to enhance enzyme-hydrolytic efficiency for sugarcane bagasse after an optimized pre-treatment with alkaline peroxide. Appl Energy 88:403–408. https://doi.org/10.1016/j.apenergy.2010.08.009

Melati RB, Sass DC, Pagnocca FC, Brienzo M (2021) Anatomic influence of sugarcane biomass on xylan solubilization. Ind Crop Prod 164:113357. https://doi.org/10.1016/J.INDCROP.2021.113357

Pereira MAF, Monteiro CRM, Pereira GN et al (2021) Deconstruction of banana peel for carbohydrate fractionation. Bioprocess Biosyst Eng 44:297–306. https://doi.org/10.1007/s00449-020-02442-1

Iha OK, Martins GBC, Ehlert E et al (2018) Extraction and characterization of passion fruit and guava oils from industrial residual seeds and their application as biofuels. J Braz Chem Soc 29:2089–2095. https://doi.org/10.21577/0103-5053.20180083

de Figueiredo FC, Carvalho AFA, Brienzo M et al (2017) Chemical input reduction in the arabinoxylan and lignocellulose alkaline extraction and xylooligosaccharides production. Bioresour Technol 228.https://doi.org/10.1016/j.biortech.2016.12.097

Wei L, Yan T, Wu Y et al (2018) Optimization of alkaline extraction of hemicellulose from sweet sorghum bagasse and its direct application for the production of acidic xylooligosaccharides by Bacillus subtilis strain MR44. PLoS ONE 13:1–15. https://doi.org/10.1371/journal.pone.0195616

Samanta AK, Jayapal N, Kolte AP et al (2013) Application of pigeon pea (Cajanus cajan) stalks as raw material for xylooligosaccharides production. Appl Biochem Biotechnol 169:2392–2404. https://doi.org/10.1007/s12010-013-0151-0

Xu F, Sun JX, Liu CF, Sun RC (2006) Comparative study of alkali- and acidic organic solvent-soluble hemicellulosic polysaccharides from sugarcane bagasse. Carbohydr Res 341:253–261. https://doi.org/10.1016/j.carres.2005.10.019

Brienzo M, Arantes V, Milagres AMF (2008) Enzymology of the thermophilic ascomycetous fungus Thermoascus aurantiacus. Fungal Biol Rev 22:120–130

Goswani GK, Rawat S (2015) Microbial Xylanase and their Applications. Int J Cur Res Acad Revi 3:436–450

Carvalho AFA, De Oliva Neto P, De Almeida PZ et al (2015) Screening of xylanolytic Aspergillus fumigatus for prebiotic xylooligosaccharide production using bagasse. Food Technol Biotechnol 53:428–435. https://doi.org/10.17113/ftb.53.04.15.4160

Wang Y, Cao X, Zhang R et al (2018) Evaluation of xylooligosaccharide production from residual hemicelluloses of dissolving pulp by acid and enzymatic hydrolysis. RSC Adv 8:35211–35217. https://doi.org/10.1039/c8ra07140c

Aragon C, Ruiz-Matute A, Corzo N et al (2018) Production of Xylo-oligosaccharides (XOS) by controlled hydrolysis of Xylan using immobilized Xylanase from Aspergillus niger with improved properties. Integr Food Nutr Metab 5:1–9. https://doi.org/10.15761/ifnm.1000225

Li H, Xiong L, Chen X et al (2019) Enhanced enzymatic hydrolysis of wheat straw via a combination of alkaline hydrogen peroxide and lithium chloride/N, N-dimethylacetamide pretreatment. Ind Crop Prods 137:332–338. https://doi.org/10.1016/J.INDCROP.2019.05.027

Li H, Chen X, Xiong L et al (2019) Stepwise enzymatic hydrolysis of alkaline oxidation treated sugarcane bagasse for the co-production of functional xylo-oligosaccharides and fermentable sugars. Bioresour Technol 275:345–351. https://doi.org/10.1016/J.BIORTECH.2018.12.063

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES—Finance Code 001), and support of the São Paulo Research Foundation (FAPESP, process 2017/22401–8).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pereira, B.S., de Freitas, C., Contiero, J. et al. Enzymatic Production of Xylooligosaccharides from Xylan Solubilized from Food and Agroindustrial Waste. Bioenerg. Res. 15, 1195–1203 (2022). https://doi.org/10.1007/s12155-021-10373-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10373-2