Abstract

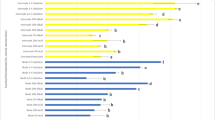

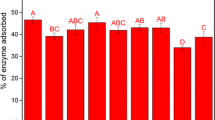

The sugarcane bagasse is a heterogeneous material and needs a pretreatment to breakdown its complex structure to make cellulose accessible to enzyme action. This study aimed to evaluate pseudo-lignin formation, enzymatic hydrolysis of sugarcane fractions (leaf, external fraction, internode, and node), and bagasse after partial delignification and acid pretreatment. The leaf and external fraction presented the highest content of lignin, and external fraction was the most recalcitrant material resulting in lower glucose release. Pretreatment with diluted sulfuric acid (20% m/m or 2% m/v) generated 5 g/L of acetic acid and 2.07 g/L of 5-hydroxymethylfurfural (external fraction in natura and leaf extractive-free, respectively). Furfural ranged between 0.11 g/L (node delignified) and 0.06 g/L (leaf, external fraction, and node in natura). A decrease was observed in pseudo-lignin formed with extractive-free and delignified biomasses, with different structure compared with non-delignified samples. The biomass partial delignification and subsequent pretreatment with dilute acid generate a material with fragmented anatomical structure, with improved cellulose accessibility, favoring enzymatic hydrolysis achieving more than 90% of glucose yield (up to 12 g/L). This study has shown strategies to decrease material heterogeneity and avoid pseudo-lignin formation as it results in lower recalcitrance and better efficiency of the enzymatic hydrolysis.

Similar content being viewed by others

Data Availability

Not applicable.

References

Bezerra TL, Ragauskas AJ (2016) Review a review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels Bioprod Biorefin 10:634–647. https://doi.org/10.1002/bbb

Brienzo M, Ferreira S, Vicentim MP, de Souza W, Sant’Anna C (2014) Comparison study on the biomass recalcitrance of different tissue fractions of sugarcane culm. Bioenergy Res 7:1454–1465. https://doi.org/10.1007/s12155-014-9487-8

Brienzo M, Abud Y, Ferreira S, Corrales RCNR, Ferreira-Leitão VS, Souza W, Sant’Anna C (2016) Characterization of anatomy, lignin distribution, and response to pretreatments of sugarcane culm node and internode. Ind Crop Prod 84:305–313

Food and Agriculture Organization of the United Nations - FAO (2018) Faostat. http://www.fao.org/faostat/en/#rankings/countries_by_commodity

Shimizu FL, Monteiro PQ, Ghiraldi PHC, Melati RB, Pagnocca FC, Souza W, Sant’Anna C, Brienzo M (2018) Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind Crop Prod 115:62–68. https://doi.org/10.1016/j.indcrop.2018.02.024

Zhuang J, Wang X, Xu J, Wang Z, Qin M (2017) Formation and deposition of pseudo-lignin on liquid-hot-water-treated wood during cooling process. Wood Sci Technol 51:165–174. https://doi.org/10.1007/s00226-016-0872-7

Ma X, Yang X, Zheng X, Chen L, Huang L, Cao S, Akinosho H (2015) Toward a further understanding of hydrothermally pretreated holocellulose and isolated pseudo lignin. Cellulose 22:1687–1696. https://doi.org/10.1007/s10570-015-0607-1

Rasmussen H, Sørensen HR, Meyer AS (2014) Formation of degradation compounds from lignocellulosic biomass in the biorefinery: sugar reaction mechanisms. Carbohydr Res 385:45–57. https://doi.org/10.1016/j.carres.2013.08.029

Trček J, Mira NP, Jarboe LR (2015) Adaptation and tolerance of bacteria against acetic acid. Appl Microbiol Biotechnol 99:6215–6229. https://doi.org/10.1007/s00253-015-6762-3

Schmatz AA, Tyhoda L, Brienzo M (2020) Sugarcane biomass conversion influenced by lignin. Biofuels Bioprod Biorefin 14:469–480. https://doi.org/10.1002/bbb.2070

Govender M, Bush T, Spark A, Bose SK, Francis RC (2009) An accurate and non-labor intensive method for the determination of syringyl to guaiacyl ratio in lignin. Bioresour Technol 100:5834–5839. https://doi.org/10.1016/j.biortech.2009.06.009

Hu F, Jung S, Ragauskas A (2012) Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour Technol 117:7–12. https://doi.org/10.1016/j.biortech.2012.04.037

Brienzo M, Fikizolo S, Benjamin Y, Tyhoda L, Görgens J (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energy 104:271–280. https://doi.org/10.1016/j.renene.2016.12.037

Costa THF, Masarin F, Bonifácio TO et al (2013) The enzymatic recalcitrance of internodes of sugar cane hybrids with contrasting lignin contents. Ind Crop Prod 51:202–211. https://doi.org/10.1016/j.indcrop.2013.08.078

Masarin F, Neves AS, Milagres AMF, Ferraz A (2013) Evaluation of a simple alkaline pretreatment for screening of sugarcane hybrids according to their in vitro digestibility. Ind Crop Prod 51:390–395. https://doi.org/10.1016/j.indcrop.2013.09.033

Masarin F, Gurpilhares DB, Baffa DCF, Barbosa MHP, Carvalho W, Ferraz A, Milagres AMF (2011) Chemical composition and enzymatic digestibility of sugarcane clones selected for varied lignin content. Biotechnol Biofuels 4:1–10. https://doi.org/10.1186/1754-6834-4-55

Li M, Pu Y, Ragauskas AJ (2016) Current understanding of the correlation of lignin structure with biomass recalcitrance. Front Chem 4:1–8. https://doi.org/10.3389/fchem.2016.00045

ABNT NBR 16550:2018 Sugarcane bagasse - chemical characterization. Brazilian National Standards Organization (2018) ABNT

Brienzo M, Tyhoda L, Benjamin Y, Görgens J (2015) Relationship between physicochemical properties and enzymatic hydrolysis of sugarcane bagasse varieties for bioethanol production. New Biotechnol 32:253–262. https://doi.org/10.1016/j.nbt.2014.12.007

Hu F, Jung S, Ragauskas A (2013) Impact of pseudolignin versus dilute acid-pretreated lignin on enzymatic hydrolysis of cellulose. ACS Sustain Chem Eng 1:62–65. https://doi.org/10.1021/sc300032j

Shimizu FL, Azevedo GO, Coelho LF et al (2020) Minimum lignin and xlan removal to improve cellulose accessibility. BioEnergy Res 13:775–785. https://doi.org/10.1007/s12155-020-10120-z

de Carvalho DM, Sevastyanova O, Penna LS et al (2015) Assessment of chemical transformations in eucalyptus, sugarcane bagasse and straw during hydrothermal, dilute acid, and alkaline pretreatments. Ind Crop Prod 73:118–126. https://doi.org/10.1016/j.indcrop.2015.04.021

Melati RB, Schmatz AA, Pagnocca FC et al (2017) Sugarcane bagasse: production, composition, properties, and feedstock potential. In: Murphy R (ed) Sugarcane: production systems, uses and economic importance. Nova Science Publishers, New York, pp 1–38

Mesa L, Morales M, González E, Cara C, Romero I, Castro E, Mussatto SI (2014) Restructuring the processes for furfural and xylose production from sugarcane bagasse in a biorefinery concept for ethanol production. Chem Eng Process 85:196–202. https://doi.org/10.1016/j.cep.2014.07.012

Rai PK, Singh SP, Asthana RK, Singh S (2014) Biohydrogen production from sugarcane bagasse by integrating dark- and photo-fermentation. Bioresour Technol 152:140–146. https://doi.org/10.1016/j.biortech.2013.10.117

Rocha GJ d M, Carlos M, Isaias Barbosa S et al (2011) Dilute mixed-acid pretreatment of sugarcane bagasse for ethanol production. Biomass Bioenergy 35:663–670. https://doi.org/10.1016/j.biombioe.2010.10.018

Martins LHS, Rabelo SC, da Costa AC (2015) Effects of the pretreatment method on high solids enzymatic hydrolysis and ethanol fermentation of the cellulosic fraction of sugarcane bagasse. Bioresour Technol 191:312–321. https://doi.org/10.1016/j.biortech.2015.05.024

Candido JP, Claro EMT, de Paula CBC, Shimizu FL, de Oliveria Leite DAN, Brienzo M, de Angelis DF (2020) Detoxification of sugarcane bagasse hydrolysate with different adsorbents to improve the fermentative process. World J Microbiol Biotechnol 36:1–12. https://doi.org/10.1007/s11274-020-02820-7

Hongdan Z, Shaohua X, Shubin W (2013) Enhancement of enzymatic saccharification of sugarcane bagasse by liquid hot water pretreatment. Bioresour Technol 143:391–396. https://doi.org/10.1016/j.biortech.2013.05.103

Soares LCSR, Chandel AK, Pagnocca FC, Gaikwad SC, Rai M, da Silva SS (2016) Screening of yeasts for selection of potential strains and their utilization for in situ microbial detoxification (ISMD) of sugarcane bagasse hemicellulosic hydrolysate. Indian J Microbiol 56:172–181. https://doi.org/10.1007/s12088-016-0573-9

Singh R, Singh S, Trimukhe KD, Pandare KV, Bastawade KB, Gokhale DV, Varma AJ (2005) Lignin–carbohydrate complexes from sugarcane bagasse: preparation, purification, and characterization. Carbohydr Polym 62:57–66. https://doi.org/10.1016/j.carbpol.2005.07.011

Junior CS, Milagres AMF, Ferraz A, Carvalho W (2013) The effects of lignin removal and drying on the porosity and enzymatic hydrolysis of sugarcane bagasse. Cellulose 20:3165–3177. https://doi.org/10.1007/s10570-013-0032-2

Rocha GJM, Gonçalves AR, Nakanishi SC, Nascimento VM, Silva VFN (2015) Pilot scale steam explosion and diluted sulfuric acid pretreatments: comparative study aiming the sugarcane bagasse saccharification. Ind Crop Prod 74:810–816. https://doi.org/10.1016/j.indcrop.2015.05.074

Acknowledgements

This study was supported by Brazilian Council for Research and Development – CNPq. (process number: 401900/2016-9).

Funding

This study was supported by Brazilian Council for Research and Development – CNPq (process number: 401900/2016-9).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Code Availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Schmatz, A.A., Salazar-Bryam, A.M., Contiero, J. et al. Pseudo-Lignin Content Decreased with Hemicellulose and Lignin Removal, Improving Cellulose Accessibility, and Enzymatic Digestibility. Bioenerg. Res. 14, 106–121 (2021). https://doi.org/10.1007/s12155-020-10187-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10187-8