Abstract

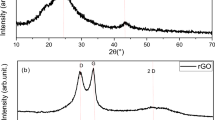

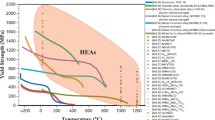

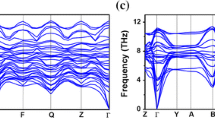

High density MnAl–C magnets with enhanced coercivity and remanent magnetization were prepared by high-pressure compaction of the \(\uptau \)-phase obtained by annealing the as-prepared gas-atomized powders, which are spherical in shape with size in the range of 1–7 \(\upmu \)m. The as-prepared gas-atomized powders were composed of \(\upvarepsilon \)- as the major phase and \(\upgamma _{2}\)- as the minor phase. The massive phase transformation of \(\upvarepsilon \rightarrow \uptau \) in the gas-atomized powders occurs at 720 K and accomplishes at 806 K, both of which are lower than those of the water-quenched \(\upvarepsilon \)-MnAl–C alloys with the same composition. An optimized temperature of 760 K, at which the decomposition of metastable \(\uptau \)-phase was minimized, was selected to prepare the ferromagnetic \(\uptau \)- from the \(\upvarepsilon \)-phase. The spherical \(\uptau \)-phase powders were pressed at room temperature into two dimensional plates that stack along the direction of compaction, forming high density (98.6%) bulk magnets that exhibit larger coercivity and higher remanent magnetization than that of the \(\uptau \)-phase powders. The grain size of the compacted samples was observed to be in the range of 10–100 nm. The coercivity (0.34 T) of the dense samples is twice as large as that of the \(\uptau \)-phase powders, owing to the refined grain size and enlarged dislocation density resulting from high-pressure compaction.

Similar content being viewed by others

References

Hindrichs G 1908 Z. Anorg. Chem. 59 414

Kono H 1958 J. Phys. Soc. Jpn. 13 1444

Koch A J, Hokkeling P, van der Steeg M G and de Vos K J 1960 J. Appl. Phys. 31 S75

Zhang C, Zhang T, Wang J, Zhao S, Wu Y and Jiang C 2018 Scr. Mater. 143 72

Nieves P, Arapan S, Schrefl T and Cuesta-Lopez S 2017 Phys. Rev. B 96 224411

Thielsch J, Bittner F and Woodcock T G 2017 J. Magn. Magn. Mater. 426 25

Shao Z, Zhao H, Zeng J, Zhang Y, Yang W, Lai Y et al 2017 AIP Adv. 7 056213

Si P Z, Qian H D, Choi C J, Park J, Han S, Ge H L et al 2017 Materials 10 1016

Lee J G, Wang X L, Zhang Z D and Choi C J 2011 Thin Solid Films 519 8312

Law J Y, Rial J, Villanueva M, López N, Camarero J, Marshall L G et al 2017 J. Alloys Compd. 712 373

Ohtani T, Kato N, Kojima S, Kojima K, Sakamoto Y, Konno I et al 1977 IEEE Trans. Magn. 13 1328

Madugundo R, Alkan O K and Hadjipanayis G C 2016 AIP Adv. 6 056009

Pasko A, Mazaleyrat F, Varga L K, Stamenov P S and Coey J M D 2014 IEEE Trans. Magn. 50 6971500

Chaturvedi A, Yaqub R and Baker I 2014 Metals 4 20

Tyrman M, Ahmim S, Pasko A, Etgens V, Mazaleyrat F, Weben S Q et al 2018 AIP Adv. 8 056217

Bittner F, Freudenberger J, Schultz L and Woodcock T G 2017 J. Alloys Compd. 704 528

Si P Z, Qian H D, Choi C J, Park J and Ge H L 2018 J. Magn. Magn. Mater. 451 540

Wang X, Lee J, Lee J, Kim H, Choi C and Zhang Z 2012 Met. Mater. Int. 18 711

Chaturvedi A, Yaqub R and Baker I 2014 J. Phys.: Condens. Matter 26 064201

Singh N, Mudgil V, Anand K, Srivastava A K, Kotnala R K and Dhar A 2015 J. Alloys Compd. 633 401

Palanisamy D, Madras G and Chattopadhyay K 2017 J. Magn. Magn. Mater. 439 181

Madugundo R and Hadjipanayis G C 2016 J. Appl. Phys. 119 013904

Acknowledgements

This work was supported by the Future Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT, and Future Planning (2016M3D1A1027835). P Z Si and H L Ge are grateful to the National Natural Science Foundation of China (nos. 11074227 and 51671177). China Jiliang University and Korea Institute of Materials Science have equal rights to the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Si, P.Z., Park, J., Qian, H.D. et al. Enhanced magnetic performance of bulk nanocrystalline MnAl–C prepared by high pressure compaction of gas atomized powders. Bull Mater Sci 42, 95 (2019). https://doi.org/10.1007/s12034-019-1768-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1768-6