Abstract

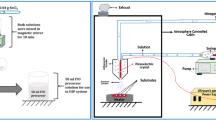

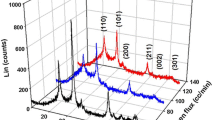

Low temperature PECVD (Plasma Enhanced Chemical Vapour Deposition) deposited SiC thin films are promising materials for development of high temperature working MEMS (Microelectromechanical System) due to their excellent mechanical properties, non-corrosive nature and ability to withstand high temperature. However, the surface roughness of such thin films is the main obstacle to achieve thicker thin films for MEMS applications as the surface more rougher by increasing the thickness of PECVD SiC thin films. Therefore, in this present study, thicker SiC thin films were deposited by PECVD process by using the CH4 and SiH4 as the precursor gases in presence of Ar as the carrier gas and two process parameters i.e. RF (Radio Frequency) power with mixed frequency condition and flow ratio of silane to methane were varied by keeping the temperature and pressure constant to investigate the influence of these parameters on the growth rate, surface roughness and morphology of SiC thin films. It was observed that both the RF power (with the mixed frequency condition) and flow ratio of SiH4/CH4 can control the growth rate, surface roughness and morphology of the PECVD SiC thin films. Higher the carbon content in the thin films the surface became more smoother whereas the surface became for rougher by increasing the RF power.

Similar content being viewed by others

References

Azevedo R G, Jones D G, Jog A V, Myers D R, Chen L, Fu X, Mehregany M, Wijesundara M B J and Pisano A P 2007 IEEE Sens. J. 7 568

Wu C, Zorman C A and Mehregany M 2006 IEEE Sens. J. 6 316

Roy S, DeAnna R G, Zorman C A and Mehregany M 2002 IEEE Trans. Electron. Devices 49 2323

Liu L, Tang W, Zheng B and Zhang H 2011 Proceedings of the 2011 6th IEEE international conference on nano/microengineered and molecular systems, February 20–23, Kaohsiung, Taiwan, p 146

El Khalfi A, El Maati Ech-chamikh, Ijdiyaou Y, Azizan M, Essafti A, Nkhaili L and Outzourhit A 2014 Spectrosch. Lett.: Int. J. Rapid Commun. 47 392

Chandra S, Kumar S and Bose G 2012 J. Micromech. Microeng. 22 025010

Sarro P 2000 Sens. Actuators 82 210

Zorman C A, Rajgopal S, Fu X A, Jezeski R, Melzak J and Mehregany M 2002 Electrochem. Solid-State Lett. 5 99

Fu X, Dunning J L, Zorman C A and Mehregany M 2005 Sens. Actuators A 119 169

Liu F, Carraro C, Pisano A P and Maboudian R 2010 J. Micromech. Microeng. 20 035011

Pelegrini M V, Rehder G P and Pereyra I 2010 Phys. Status Solidi C 7 786

Guo H, Wang Y, Chen S, Zhang G, Zhang H and Li Z 2006 Proceedings of the 1st IEEE international conference on nano/microengineered and molecular systems, January 18–21, Zhuhai, China

Ricciardi C, Primiceli A, Germani G, Rusconi A and Giorgis F 2006 J. Non-Cryst. Solids 352 1380

Huran J, Hotovy I, Kobzev A P and Balalykin N I 2004 Thin Solid Films 459 149

Milan P, Vladimír S, Miroslav M, Jozef H and Juraj O 2011 34th international spring seminar on electronics technology (ISSE), 11–15 May, Tratanska Lomnica

Prado R J, Fantini M C A, Tabacnils M H, Cardoso C A V, Pereyra I and Flank A M 2001 J. Non-Cryst. Solids 283 1

Kunle M, Janz S, Nickel K G and Eibl O 2011 Phys. Status Solidi A 208 1885

Kim Y, Cho S, Hong B, Suh S, Jang G and Yoon D 2002 Mater. Trans. 43 2058

Awad Y, El Khakani M A, Brassard D, Smirani R, Camiré N, Lessard M, Aktik C, Scarlete M and Mouine J 2010 Thin Solid Films 518 2738

Avram M, Avram A, Bragaru1 A, Chen B, Poenar D and Iliescu C 2010 Semiconductor conference (CAS), international (Vol. 01), 11–13 October

Hua Z, Liao X, Diao H, Kong G, Zeng X and Xu Y 2004 J. Cryst. Growth 264 7

Oliveira A R and Carreno M N P 2006 J. Non-Cryst. Solids 352 1392

Kaneko T, Nemoto D, Horiguchi A and Miyakawa N 2005 J. Cryst. Growth 275 1097

Mernagh V A, Kelly T C, Ahern M, Kennedy A D, Adriaansen A P M, Ramaekers P P J, McDonnell L and Koekoek R 1991 Surf. Coat. Technol. 49 462

Mastelaro V, Flank A M, Fantini M C A, Bittencourt D R S, Carreno M N P and Pereyra I 1996 J. Appl. Phys. 79 1324

Rava P, Crovini G, Demichelis F, Giorgis F and Pirri C F 1996 J. Appl. Phys. 80 4116

Acknowledgements

The financial support was provided by ADA: NP-MASS under Grant no. 1.27 to carry out this work. The PECVD depositions were carried out at CeNSE, IISc Bangalore. We would like to thank the clean room manager Dr Raghavan and Aditi for their clean room assistance during the depositions of samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

PERI, B., BORAH, B. & DASH, R.K. Effect of RF power and gas flow ratio on the growth and morphology of the PECVD SiC thin film s for MEMS applications. Bull Mater Sci 38, 1105–1112 (2015). https://doi.org/10.1007/s12034-015-0881-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0881-4