Abstract

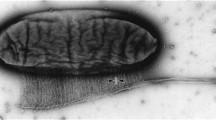

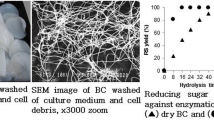

Structure and properties of bacterial cellulose (BC) produced by trickling fermentation were studied. The following indexes, such as extrinsic shapes, microstructure, chemical structure, purity, water holding capacity, porosity, and thermogravimetric characteristics, are recommended for assessing the structure and properties of bacterial cellulose. With the comparison to bacterial cellulose produced by static fermentation and shaking fermentation, the results showed that for different BC cultivation methods, the extrinsic shapes, synthetic mode, and microstructure were different. The basic consistency of the infrared spectrogram from three kinds of bacterial cellulose reflected that the chemical structures were very similar. But the –OH associating degree of trickling fermentation BC was higher, and the polymerization degree, purity, water holding capacity, porosity, and thermal stability of trickling fermentation BC were also higher than those of static fermentation BC and shaking fermentation BC. But the crystallinity and crystal grain size of trickling fermentation BC were less than those of static fermentation BC and greater than those of shaking fermentation BC and plant fiber. These above structure and properties of trickling fermentation BC could reference bacterial cellulose’s application in food and material field.

Similar content being viewed by others

References

Iguchi, M., Yamanaka, S., & Budhiono, A. (2000). Bacterial cellulose—a masterpiece of nature’s arts. Journal of Materials Science, 35, 261–270.

Wu, Z. Y., Li, C., Liang, H. W., Chen, J. F., & Yu, S. H. (2013). Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angewandte Chemie International Edition, 125, 2997–3001.

Watanabe, K., Tabuchi, M., Morinaga, Y., & Yoshinaga, F. (1998). Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose, 5, 187–200.

Chao, Y., Ishida, T., Sugano, Y., & Shoda, M. (2000). Bacterial cellulose production by Acetobacter xylinum in a 50-l internal-loop airlift reactor. Biotechnology and Bioengineering, 68, 345–352.

Coucheron, D. H. (1991). An Acetobacter xylinum insertion sequence element associated with inactivation of cellulose production. Journal of Bacteriology, 173, 5723–5731.

Masayuki, O., Ikuro, H., Kiyoshi, T., & Tomoko, A. (2002). Silicone rubber membrane bioreactors for bacterial cellulose production. Biotechnology and Bioprocess Engineering, 7, 289–294.

Shao, Z. Q. (2007). Cellulose ethers (pp. 226–227). Beijing: Chemical Industry.

Zhu, G. J., & Wang, Z. X. (1994). Industrial microbiology experiments technical manual (pp. 209–213). Beijing: China Light Industry.

Robertson, J. A., & Eastwood, M. A. (1981). An examination of factors which may affect the water holding capacity of dietary fibre. British Journal of Nutrition, 45, 83–87.

Mancini, C. E., Berndt, C. C., Sun, L., & Kucuk, A. (2001). Porosity determinations in thermally sprayed hydroxyapatite coatings. Journal of Materials Science, 36, 3891–3896.

Kitaoka, K., Yamamoto, H., Tani, T., Hoshijima, K., & Nakauchi, M. (1997). Mechanical strength and bone bonding of a titanium fiber mesh block for intervertebral fusion. Journal of Orthopaedic Science, 2, 106–113.

Mihranyan, A., Llagostera, A. P., Karmhag, R., Strømme, M., & Ek, R. (2004). Moisture sorption by cellulose powders of varying crystallinity. International Journal of Pharmaceutics, 269, 433–442.

Zhang, L. N., Xue, Q., Mo, Z. S., & Jin, X. (2003). Current researching methods on polymer physics (pp. 194–195). Hubei: Wuhan University.

Feng, Y. H., Li, J. C., Lin, Q., Wang, X. B., Wu, Z. X., Pang, S. J., et al. (2007). Crystallinity and thermal decomposition of dialdehyde celluloses from bacterial cellulose. Key Engineering Materials, 330–332, 1289–1292.

Kunihiko, W., Mari, T., Yasushi, M., & Fumihiro, Y. (1998). Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose, 5, 187–200.

Meng, L. Z., Gong, S. Z., & He, Y. B. (1997). Organic spectroscopy (pp. 265–290). Hubei: Wuhan University.

Wang, M. (2008). MsD thesis, Qing Dao University, Qing Dao, China.

Cheng, K. C., & Jeffrey, M. C. (2009). Effect of different additives on bacterial cellulose production by Acetobacter xylinum and analysis of material property. Cellulose, 16, 1033–1045.

Zhao, X. X., Zhu, P., Wang, M., & Dong, Z. H. (2009). The comparison between bacterial cellulose and regenerated bacterial cellulose on structure and properties. Synthetic Fibre, 38, 6–10.

Ma, X. (2003). PhD thesis, Tianjin University of Technology, Tianjin, China.

Huang, D., & Wang, Q. L. (2008). Discussion on the production of bacterial cellulose by Acetobacter xylinum QAX993 fermentation conditions. China Brewing, 38, 36–37.

Oikawa, T., Morimo, T., & Ameyama, M. (1995). Production of cellulose from D-arabitol by Acetobacter xylinum. Bioscience, Biotechnology, and Biochemistry, 59(1564), 1565.

Tang, W. H., Jia, S., Jia, Y., & Yang, H. J. (2010). The influence of fermentation conditions and post-treatment methods on porosity of bacterial cellulose membrane. World Journal of Microbiology and Biotechnology, 26, 125–131.

Karathanos, V. T., Kanellopoulos, N. K., & Belessiotis, V. G. (1996). Development of porous structure during air drying of agricultural plant products. Journal of Food Engineering, 29(167), 183.

Um, I. C., Ki, C. S., Kweon, H., Lee, K. G., Lhm, D. W., & Park, Y. H. (2004). Wet spinning of silk Polymer II. Effect of drawing on the structure characteristics and properties of filament. International Journal of Biological Macromolecules, 34, 107–119.

Czaja, W., Romanovicz, D., & Brown, R. M. (2004). Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose, 11, 403–411.

Borzani, W., & Desouza, S. J. (1995). Mechanism of the film thickness increasing during the bacterial production of cellulose on non-agitated liquid-media. Biotechnology Letters, 17, 1271–1272.

Yoshino, T., Asakura, T., & Toda, K. (1996). Cellulose production by Acetobacter pasteurianus on silicon membrane. Journal of Fermentation and Bioengineering, 81, 32–36.

Serafica, G., Mormino, R., & Bungay, H. (2002). Inclusion of solid particle in bacterial cellulose. Applied Microbiology and Biotechnology, 58, 756–760.

Hornung, M., Ludwig, M., & Schmauder, H. P. (2007). Optimizing the production of bacterial cellulose in surface culture: a novel aeroso bioreactor working on a fed batch principle (part 3). Engineering in Life Sciences, 7, 35–41.

Marx-Figini, M., & Pion, B. G. (1974). Kinetic investigations on biosynthesis of cellulose by Acetobacter xylinum. Biochimica et Biophysica Acta, 338, 382–393.

Marx-Figini, M. (1982). The control of molecular weight and molecular weight distribution in the biogenesis of cellulose. In Cellulose and other natural polymer systems: biogenesis, structure, and degradation. Plenum, New York, pp. 243–271.

Acknowledgments

This study was sponsored by the National Natural Science Foundation of China (Grant No. 31160338) and Guizhou Province Science and Technology Fund (Grant No. [2010] 2066).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, H., Jiang, X. Structure and Properties of Bacterial Cellulose Produced Using a Trickling Bed Reactor. Appl Biochem Biotechnol 172, 3844–3861 (2014). https://doi.org/10.1007/s12010-014-0795-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-0795-4