Abstract

Pork represents a major fraction of the meat consumed worldwide but only 30% of the blood generated in slaughterhouses is re-used as raw material for food and feed. Innovative technologies and efficient processing strategies capable of generating added-value products from it are now attracting attention. In this study, the hydrolysis of porcine coagulated blood using sub-critical solvent extraction was investigated. Biomass was hydrolyzed using different temperatures (120–210 °C), applying only water (sub-critical water; SCW) or water with a low concentration of alkali (0.1 mol L−1 NaOH) and different reaction times (30–90 min). Resultant hydrolysates were analyzed for crude and soluble protein, peptide profile, and bioactivity by combining protein quantification, antioxidant activity, and fast protein liquid chromatography measurements. Results showed that increasing temperature increases the degree of hydrolysis and that the addition of NaOH enhances the solubilization of peptides with high molecular weights. Also, hydrolysates showed interesting antioxidant activity, being 60 min the time of reaction with best antioxidant activity. Nevertheless, using only water (SCW) as solvent, without chemical additives, allows the delivering of interesting protein-based bioactive fractions. Sub-critical solvent treatment of porcine blood resulted in added-value fractions with potential bioactivities through a simple and environmentally friendly process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Porcine blood (PB) is a by-product from the meat industry produced in large volumes. In fact, blood represents up to 4% of the animal weight and for each slaughtered animal around 3 L of blood is produced. Pork represents a major fraction of the meat consumed worldwide but only 30% of the blood generated in slaughterhouses is re-used as raw material for food, feed, and emulsifiers, being the most of it discarded, representing a high cost and environmental impact (Álvarez et al., 2013; Bah et al., 2013, 2016; Lee & Song, 2009; Sorapukdee & Narunatsopanon, 2017; Wei & Chiang, 2009). It is expected that meat consumption will double by 2050, and consequently, the current large volumes of blood being produced in slaughterhouses will also increase. Pork is one of most consumed meat worldwide; thus, PB can become one of the most problematic by-products of the meat industry (Henchion et al., 2017). Besides the high environmental impact of meat products, the predictable nutrient shortage (including protein) reinforces the idea that the rational use of meat protein is strictly necessary (Mottet et al., 2017; Zampiga et al., 2021). Therefore, reducing animal-based protein wastes to a minimum value (preferably zero), allowing its integral use, is crucial to increase sustainability and decrease the pressure on these protein sources. Innovative technologies and efficient processing strategies capable of generating added-value products from these important protein sources are now attracting attention.

Blood is mostly composed of moisture (75–82%) and proteins (17–18%), being hemoglobin the main representative one (~ 70%). Besides its nutritional value, it is considered a non-allergenic protein source (when compared with vegetable sources such as soy), rich in important micronutrients such as iron (Álvarez et al., 2013; Bah et al., 2013; Sorapukdee & Narunatsopanon, 2017). The use of blood and its derivatives have been extensively explored for food applications to take advantage of these properties. Blood derivatives, such as hemoglobin, globin, plasma, transglutaminase, fibrinogen, and thrombin, have been studied for iron fortification, as fat and egg white replacers and as protease inhibitors, when incorporated in several food products (Bah et al., 2013). Also, food products, such as blood sausages, black puddings, and blood tofu, make use of whole animal blood and are used as protein sources in some societies (Bah et al., 2013). Moreover, plasma proteins are currently used in food industry as emulsifiers (Bah et al., 2013).

Considering that proteins are one of the main constituents of the blood, the possibility to recover the protein contained in slaughterhouse blood that used to be discarded and to use it on a large scale has been gaining some attention not only to avoid the loss of possible valued material that could add economic value to meat industry, but also to reduce the pollutant power of its disposal (Bah et al., 2013; Hyun & Shin, 1998; Wei & Chiang, 2009) and manage protein shortage expected in the near future.

Hydrolysis has been used as a sustainable method for protein recovery, resulting in the production of bioactive protein hydrolysates (Hai, 2020; Hou et al., 2017). Protein hydrolysates have been used for nutritional applications for over 50 years, in particular to supply the needs of individuals with problems in protein digestion or allergenicity. However, over the recent years, several new applications for the use of these protein fractions have emerged, extending its use to the food, health, and cosmetics industry due to their functional and bioactive properties (e.g., antimicrobial, anti-inflammatory, antioxidant, and antihypertensive). This makes them more attractive for the development of innovative human and animal foodstuffs (Álvarez et al., 2013; Jin et al., 2020). The production of protein hydrolysates can be done using different approaches, namely enzymes, microorganisms, or chemicals (acids or alkalis) (Hai, 2020; Hou et al., 2017). Chemical hydrolysis is a process easy to control and cheap, but the extreme alkali or acidic conditions could result in the total destruction of certain amino acids (Hou et al., 2017). Despite enzymatic hydrolysis is gaining industrial interest, as an efficient and sustainable method, it can be an expensive method (da Silva, 2018; Gagaoua, 2018).

Currently, new eco-friendly methodologies aiming at protein recovery from food industry by-products have been exploited, namely sub-critical solvent extraction (SSE) or sub-critical water hydrolysis (SWH), if the solvent used is water. This method uses water in sub-critical state (temperatures between 100 and 374 °C and pressures between 0.10 and 22 MPa) to maintain water in the liquid state during the whole process (King, 2000; Marcet et al., 2016). When water is in the sub-critical state (SCW), it acquires unique properties: (i) the dielectric constant decreases, which enables its use as solvent in the recovery of more hydrophobic matters, and (ii) the water ionic product increases, increasing the amount of OH− and H+ ions available and consequently its potential to act as an acid- or base-like catalyst in the hydrolysis of different types of matrixes (Álvarez et al., 2012; Tavakoli & Yoshida, 2006). When SWH or SSE is applied under appropriate combination of temperature, pressure, and reaction time, proteins can be hydrolyzed into peptides and amino acids (Marcet et al., 2016).

SWH has been applied to hydrolyze and extract several compounds from plants, algae, and animal by-products, being proteins one of the most studied biomolecules (Álvarez-Viñas et al., 2021; Marcet et al., 2016). The use of SWH to recover peptides and amino acids from different protein-enriched wastes is reported in the literature. In fact, studies with wastes from animal source, like fish entrails, scallop and abalone viscera, blood hemoglobin, hog hair, poultry wastes, sericin, and fibroin have shown that protein-rich wastes or by-products from these sources can be revalorized by SWH (Álvarez et al., 2012; Álvarez-Viñas et al., 2021; Esteban et al., 2010; Kang et al., 2001; Lamoolphak et al., 2008; Tavakoli & Yoshida, 2006; Zheng et al., 2019; Zhu et al., 2010).

Most of the published work on porcine blood has been concentrated in exploiting its purified derivatives, namely, hemoglobin (Álvarez et al., 2012, 2013, 2016; Li et al., 2022) and plasma (Samsalee & Sothornvit, 2020; Wei & Chiang, 2009). In fact, purified porcine hemoglobin, extracted from blood by-products, was previously hydrolyzed to produce peptides with functional and antioxidant properties, by alkaline hydrolysis (Álvarez et al., 2013; Li et al., 2022) and by SWH under a nitrogen stream (Álvarez et al., 2012) or SWH coupled with oxygen injection (Álvarez et al., 2016). Also, porcine plasma proteins were exploited to produce bioactive peptides by enzymatic hydrolysis (Wei & Chiang, 2009) or to produce films for packaging (Samsalee & Sothornvit, 2020). However, the studies that explore the use of whole porcine blood (as it is produced in slaughterhouses) to extract protein and produce bioactive protein hydrolysates, are all focused on using enzymatic hydrolysis and, in some cases, also peptide fractionation (Araújo-Rodrigues et al., 2022; Verma et al., 2019), which can be expensive to apply at an industrial scale.

SWH has been proven to be an inexpensive, scalable, environmentally friendly, and effective technology to extract protein from several matrixes and to produce functional and bioactive protein hydrolysates (Álvarez-Viñas et al., 2021; Marcet et al., 2016; P. Zheng et al., 2019). Although it has been applied in the hydrolysis of purified hemoglobin (with a purifying step using osmotic shock followed by chloroform extraction), there are no studies of its usage for the valorization of whole porcine blood. So, the main objective of this study was to assess the feasibility of using SSE to extract and hydrolyze proteins from porcine coagulated blood by-products generated by the meat industry, targeting food and feed applications. The whole blood was used as it is collected and treated commonly in the slaughterhouses, without any extraction, purification, and lyophilization steps prior to the hydrolysis to isolate specific proteins. Specific aims included evaluating the effect of processing parameters such as temperature, time, and solvent (water or water with 0.1 mol L−1 alkali) on biomass solubilization, protein content/solubilization, proteins/peptides profile and bioactive potential, and tuning the hydrolysis step to allow using only water (without alkali) as solvent.

Material and Methods

Reagents

Bradford dye reagent was purchased from Alfa Aesar (USA). Sodium hydroxide (NaOH); bovine serum albumin (BSA); 2,2-diphenyl-1-picrylhydrazyL (DPPH); and 2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) were supplied by Sigma-Aldrich (USA). All other chemicals were analytical grade.

Materials: Blood Sampling

Porcine coagulated blood (PCB) was supplied by the licensed slaughterhouse Central Carnes – Matadouro Central Entre Douro e Minho, S.A (Vila Nova de Famalicão, Portugal; Veterinary Control Number D36). Blood collection followed the animal by-products regulation of the European Parliament (EC No 1069/2009) for category 3 (European Parliament and Council, 2009) as previously described by Araújo-Rodrigues et al. (2022). Blood samples were divided into aliquots of 200 g and frozen at − 20 °C until use.

Dry Weight of PCB

The determination of the dry weight of PCB was made using the standard gravimetric AOAC Method 950.46. (2005), by weighing samples in a precision analytical balance before and after drying at 105 °C for 16 h in an oven (Thermo Electron Corporation, USA). The assay was performed in triplicate using 1 g of CB for each replica. Dry weight (%) was calculated using the equation:

where D corresponds to the weight of the dry biomass and crucible; C corresponds to the weight of the crucible alone; and W corresponds to the weight of the wet biomass and crucible.

Preparation of Protein Hydrolysates by Sub-Critical Solvent Extraction (SSE)

Hydrolysis experiments were performed in a pressurized reactor with temperature control (Parr 4523 Fixed Head Bench Reactor equipped with Parr 4848 reactor controller, Parr, USA). Each run was conducted using PCB at 50 g dry weight L−1, considering a volume of 0.4 L and a stirring rate of 160 rpm. The solvents used were distilled water and NaOH at 0.1 mol L−1. After the hydrolysis, the hydrolysates were collected from the vessel, filtered, and pH was measured. A small sample of each hydrolysate was collected for dry weight determination. The remaining amount was neutralized (pH = 7.00 ± 0.02). A small sample was kept at − 20 °C for Bradford and antioxidant assays. The remaining liquid was dried at 50 °C in glass recipients using an oven (Termaks, Norway), for further analyses.

Firstly, assays were performed in order to evaluate the effect of temperature and solvent on biomass solubilization yield and protein content. So, different temperatures (120 °C, 150 °C, 180 °C, and 210 °C) were tested using both SCW and NaOH at 0.1 mol L−1 as solvents, during 60 min. The second phase of the study was focused on the reaction time effect and used only SCW as solvent at 150 °C, 180 °C, and 210 °C. Reaction times tested were 30 min, 60 min, and 90 min. Pressure in the different treatments was slightly higher than the saturation water vapor pressure for each operational temperature (i.e., 150 °C: 6 bar; 180 °C: 8 bar; 210 °C: 20 bar).

Biomass Solubilization Yields

Biomass solubilization yields, expressed as the percentage of PCB solubilization, were determined gravimetrically using the following formula:

where B is the total mass (g; dry weight) of PCB used for hydrolysis and IF is the mass (g; dry weight) of the insoluble fraction collected from the reactor vessel after hydrolysis.

Protein Content

The protein content on hydrolysates was analyzed by the Bradford assay (Bradford, 1976; Kruger, 2009), using BSA as a standard in concentrations ranging from 0 to 1.2 mg/mL (R2 = 0.985). Briefly, the reaction occurred by mixing 20 μL of each hydrolysate with 180 μL of Bradford Dye Reagent in a 96 well plate. Absorbance of each sample was measured at 595 nm against a control treated as above but using 20 μL of distilled water. The results obtained were converted into protein (g) per g of hydrolysate (gprotein g−1 hydrolysate).

Crude protein content in the dried hydrolysates and CB was also measured by the Kjeldahl method. Briefly, 0.5 g of each sample was added to a digestion flask along with 10 mL of sulfuric acid 96–98% and selenium tablets. Digestion was performed using the meat AOAC program from the Digestor™ auto 2508 (Foss Analytic) and the distillation and titration were conducted by an automatic Kjeltec™ 8400 (Foss Analytic) unit. The measured nitrogen content (%) was converted into protein content (%) using a conversion factor of 6.25, value generally used in literature for meat products and petfood (AOAC Method 981.10, 2005; Mæhre et al., 2018). Protein content was then expressed as protein (g) per g of hydrolysate (gprotein g−1 hydrolysate).

Determination of Molecular Weight (MW) of Proteins and Peptides Hydrolysates

Proteins and peptides’ profiles were assessed by gel filtration chromatography, using a fast protein liquid chromatography (FPLC) AKTA Pure 25 system as described by Voss et al. (2019) with few modifications. Two gel filtration columns were used namely, Superdex 200 increase10/300 GL and Superdex peptide 10/300 GL (GE Healthcare Life Sciences, Freiburg, Germany) and the flow rate applied was 0.5 mL min−1. The mobile phase used was 0.025 M phosphate buffer (pH 7) with 0.15 M sodium chloride (NaCl) and 0.2 g L−1 of sodium azide (NaN3). The absorbance was monitored at 280 nm. Standard proteins with a known molecular weight (MW) were used to establish an MW curve and determine the MW of proteins and peptides namely, thyroglobulin (669 kDa), aldolase (158 kDa), conalbumin (75 kDa), ovalbumin (43 kDa), carbonic anhydrase (29 kDa), ribonuclease A (13.7 kDa), and an antihypertensive peptide (1.2 kDa). UNICORN 7.0 software was used to analyze the profile of blood hydrolysates.

Antioxidant Activity of the Hydrolysates

The antioxidant activity of the hydrolysates was evaluated by two different methods namely, DPPH and ABTS assays.

DPPH

The antioxidant activity of the hydrolysates was assessed according to the DPPH method, as described by Teixeira-Guedes et al. (2019), with slight modifications. Hydrolysates were diluted with distilled water to a final concentration of 5 g dry weight L−1. Briefly, 20 μL of hydrolysates was mixed with 180 μL of DPPH (0.3 mM in methanol). Reactions occurred in 96-well plates and the absorbance at 515 nm was measured at times 0 min and 60 min. Blanks used 20 μL of hydrolysates and 180 μL of methanol. Control used 20 μL of methanol and 180 μL of DPPH. Antioxidant activity of hydrolysates was determined according to the following formula:

where Ac is the absorbance of control at t = 0 min and Ah is the absorbance of hydrolysates at 60 min – absorbance of corresponding blanks at 60 min.

ABTS

The antioxidant activity of the hydrolysates was also evaluated according to the ABTS method, as described by Domínguez-Perles et al. (2014) and Teixeira-Guedes et al. (2019), with some modifications. Hydrolysates used to be assayed were diluted with distilled water to a final concentration of 5 g dry weight L−1. Briefly, the ABTS radical solution was prepared by mixing 5 mL of 7 mol L−1 ABTS solution with 88 μL of 148 mol L−1 potassium persulfate solution. Reaction mixture was allowed to react for 12–16 h at room temperature and protected from light. ABTS working solution was prepared by diluting ABTS radical solution with distilled water in a proportion of 1:40 (ABTS: distilled water). The ABTS working solution was allowed to stabilize for 1 h and absorbance at 734 nm was measured (DO = 0.7 ± 0.2).

Antioxidant activity was accessed by mixing 20 μL of hydrolysates with 180 μL of ABTS working solution. Reactions occurred in 96-well plates and the absorbance at 734 nm was measured at times 0 min and 30 min. Blanks used 20 μL of hydrolysates and 180 μL of distilled water. Control used 20 μL of distilled water and 180 μL of ABTS working solution. The antioxidant activity of hydrolysates was determined as follows:

where Ac is the absorbance of the control at t = 0 min and Ah is the absorbance of hydrolysates at 30 min – absorbance of corresponding blanks at 30 min.

Statistical Analysis

The statistical analysis was performed using GraphPad Prism software considering two-way ANOVA followed by Turkey’s multiple comparison test. The effect of temperature and solvent, for the first set of experiments, and time and temperature, for the second set of experiments, were the parameters analyzed.

Results and Discussion

Effects of Processing Parameters on PCB Solubilization

Solvent and Temperature Effect

The protein from PCB is mainly denatured and insoluble in water. Solubilization may be achieved by partial hydrolysis using different mechanisms, including temperature, chemicals, and/or enzymes (Álvarez et al., 2013; Araújo-Rodrigues et al., 2022; Jin et al., 2020). Therefore, PCB solubilization may be used as an indicator of protein hydrolysis, due to the breaking down of the protein-enriched biomass. The PCB solubilization was studied using 0.1 mol L−1 NaOH and dH2O at different temperatures (i.e., 120, 150, 180, and 210 °C) and the results are presented in Fig. 1. For a reaction time of 60 min, it was observed that, when using 0.1 mol L−1 NaOH as solvent, there were no significant differences (p > 0.05) between temperature and percentage of solubilization, being the solubilization almost complete (i.e., higher than 99%). On the other hand, when using dH2O as a solvent, there was a notable increase in PCB solubilization when the temperature increased (p < 0.0001), being the minimum (i.e., 15.9 ± 0.1%) and the maximum value (i.e., 85.8 ± 0.5%) obtained for 120 and 210 °C, respectively. This is in accordance with the principle of the SSE process, in which higher temperatures and pressures could accelerate the extraction kinetics and increase the extraction efficiency (Bogialli et al., 2007; del Río et al., 2020; Zielinski et al., 2021). When comparing the different solvents (Fig. 1), NaOH significantly increased PCB solubilization in all tested temperatures (120 to 180 °C: p < 0.0001; 210 °C: p = 0.0009). It is known that the presence of alkali solvents increases the protein extraction yields by breaking down the protein-enriched biomass and making the protein more soluble (Deleu et al., 2019), so the results are in accordance to what was expected.

Biomass solubilization yields (% PCB solubilization) obtained with SSE/SWH at different temperatures. Different letters mean significantly different (p < 0.05). Small letters analyzed the effect of temperature within the same solvent (i.e., same solvent in different temperatures). Capital letters analyzed the effect of solvent in the same temperatures (i.e., same temperature with different solvents)

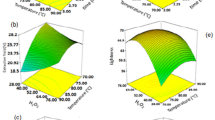

Reaction Time and Temperature Effect

Having in mind the development of greener technologies, and giving the fact that interesting biomass solubilization yields were obtained at 60 min when using water (SCW) as solvent, the effect of different temperatures (120 °C was excluded due to the very low solubilization yield) combined with different reaction times (i.e., 30, 60, and 90 min) on PCB solubilization was investigated in order to possibly eliminate the burden of using NaOH on treatment. Generally, the parameter time seemed to not affect the solubilization yields in all temperatures tested, except at 150 °C, where 90 min increased significantly (p < 0.05) the solubilization yield in comparison with a reaction of 30 min (Fig. 2).

Biomass solubilization yields (% PCB solubilization) obtained with SCW as solvent during different SWH times. Different letters mean significantly different (p < 0.05). Small letters analyzed the time effect at the same temperatures (i.e., same temperature in different times). Capital letters analyzed the temperature effect with the same reaction times (i.e., same reaction time with different temperatures)

These results suggested that parameter time only impact the PCB solubilization for lower temperatures (i.e., 150 °C or less). Thus, and besides the low solubilization observed for lower temperatures, when combining the solvent water (SCW) with higher temperatures and longer reaction times (e.g., 210 °C and 90 min), high percentage of PCB solubilization (~ 89%) can be achieved, and thus, it can be considered an alternative to alkaline hydrolysis. For all reaction times tested, results indicated that increasing the temperature increases the PCB solubilization (p < 0.05). So, optimizing reaction temperature and time seemed to be extremely important not only to obtain the desired biomass solubilization and therefore protein content, but also to minimize the solvent use and the possible energy costs related with high temperatures and long reaction times in the process.

Protein Content

Porcine blood usually contains 170 to 180 g kg−1 of proteins (Wei & Chiang, 2009), having the sample used for this work 920 g kg−1 (dry basis) of crude protein. In order to evaluate the effect of processing parameters (temperature, reaction time, and solvent) on the protein extraction from PCB, the protein contents in the hydrolysates were evaluated in both liquid (Bradford) and dried (Kjeldahl) samples.

Solvent and Temperature Effect

Regarding the use of SCW or 0.1 mol L−1 NaOH as solvents at different temperatures, it can be seen that the protein concentration determined by Kjeldahl in the hydrolysates slightly decreased (p < 0.05) with the addition of 0.1 mol L−1 NaOH (Fig. 3A), except for the hydrolysates obtained at 180 °C, probably indicating that other compounds are being co-solubilized. However, this decrease is only significant at 150 °C when using the Bradford method (Fig. 3B). Together, these results reflected an interesting behavior of SCW as solvent for protein solubilization and hydrolysis. It seemed that, despite the biomass solubilization being significantly (p < 0.05) different between solvents, as previously showed in Fig. 1, SCW seems to be slightly more selective for protein and the resulting liquid fraction has more than 90% of protein, resulting in protein isolates that can be highly valued (Fig. 3A), without the burden associated with chemicals, especially for higher temperatures (180 to 210 °C), where the solubilization yields with SWC are already interesting.

Protein content in hydrolysates obtained by SSE/SWH during 60 min. Crude protein content determined by Kjeldahl (A) and soluble protein determined by Bradford (B). Different letters mean significantly different (p < 0.05). Small letters analyzed effect of temperature within the same solvent (i.e., same solvent in different temperatures). Capital letters analyzed the effect of solvent at the same temperatures (i.e., same temperature with different solvents)

Regarding the temperature effect in hydrolysates obtained using SCW as solvent, temperature seemed to not affect the crude protein content on hydrolysates obtained (p > 0.05; Fig. 3A). However, this behavior was not seen in Bradford (Fig. 3B). This must be ascribed to a higher degree of hydrolysis (DH), because the Kjeldahl method measures the total nitrogen content of the samples, including amino acids or small peptides, while the Bradford method only detects peptides and protein with molecular weight (MW) higher than 3000 Da (Compton & Jones, 1985; Kruger, 2009; Sedmakand & Grossberg, 1977). So, this decrease in protein detected by Bradford can be a qualitative indicator of the degree of protein hydrolysis, which is expected to increase with increasing temperature, associated with the generation of free amino acids (AA) or low molecular weight peptides (MW < 3000 Da), which are not detected and quantified by the method. So, these results together with increasing PCB solubilization as temperature increases (Fig. 1) allowed to indirectly infer that the degree of hydrolysis (DH) significantly increased with temperature in the SCW system.

In the SSE system using NaOH 0.1 M as solvent, NaOH addition seemed to have a negative impact only at higher temperatures (i.e., 210 °C) (Fig. 3A). The decrease in that condition may be related with the destruction of some amino acids (AA) when exposed to high temperatures and alkalinity for a long experiment time (Friedman et al., 1984). Previous works support this hypothesis. Espinoza and Morawicki (2012) evaluated the effect of several alkali additives, including NaOH, on the SWH of whey protein and reported that for high temperatures and long reaction times (more than 20 min) the positive effect of the additives in AA yields diminished. Rogalinski et al. (2005) also observed that additive carbon dioxide influence decreases with increasing temperature when monitoring AA yield from SWH of bovine serum albumin.

Together, these results suggested that at 180 °C there are no differences in protein content of hydrolysates obtained with SCW and NaOH, both in Kjeldahl and Bradford methods (Fig. 3), while SCW yields start to be interesting (above 75%), corroborating that the use of SCW for protein extraction and hydrolysis may be a feasible technique, and an alternative to alkali hydrolysis, especially when considering higher temperatures (i.e., 210 °C), where yields in SCW are around 90%, and in which the NaOH addition decreased the crude protein content of hydrolysates, possibly due to destruction of certain AA.

Time and Temperature Effect

Regarding the use of SCW as solvent at different times of SWH treatment, it can be seen that the protein concentration in hydrolysates determined by Kjeldahl did not differ from each other in all conditions tested, and was always above 90%, resulting in a protein extract highly concentrated (Fig. 4A). Regarding soluble protein determined by the Bradford method it is possible to see that protein content tends to decrease with the increase of temperature and time (p < 0.05) (Fig. 4B), suggesting higher DH. However, differences between times at the same temperature are less sharp and not always significant, being the hydrolysis more susceptible to temperature than to the time of reaction. For higher temperatures (i.e., 210 °C), it seemed that reaction time did not affect the protein content determined by Bradford, which could mean that at 210 °C most of the protein in hydrolysates was already hydrolyzed to peptides with MW lower than 3000 Da or free AA and for higher temperatures DH from the first time tested. In fact, in literature, several reports using SWH showed that higher temperatures and longer reaction times can lead to higher DH, when extracting and hydrolyzing both proteins and sugars (Espinoza & Morawicki, 2012; Hwang et al., 2015; Moreschi et al., 2004; Sereewatthanawut et al., 2008; Zhu et al., 2008).

Protein content in hydrolysates obtained by SWH at different times of reaction. Crude protein content determined by Kjeldahl (A) and soluble protein determined by Bradford (B). Different letters mean significantly different (p < 0.05). Small letters analyzed time effect within the same temperature (i.e., same temperature with different reaction times). Capital letters analyzed the temperature effect within the same reaction time (i.e., same reaction time with different temperatures)

Combining the results from Kjeldahl with the ones from Bradford (Fig. 4A and B), it can be possible to indirectly corroborate that the decrease in the protein detected by Bradford is associated with higher DH.

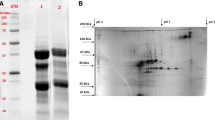

Peptide Profiles

To compare the protein and peptide profiles as well as their MW distribution in the different conditions tested, FPLC was used. The protein and peptide chromatograms of solubilized hydrolysates suggested that hydrolysates obtained using SCW as solvent possessed very similar profiles among the different treatment temperatures, differing only in the concentration according to hydrolysis time. The presence of NaOH (0.1 mol L−1) changed significantly the peptide profile of the hydrolysates in all tested temperatures. Beyond the MW peaks typically found in hydrolysates using only SCW, the chromatograms of NaOH hydrolysates also presented peaks corresponding to the solubilization of high MW peptides/proteins. This fact probably reflects the significantly higher protein solubilization yields (Fig. 1). Furthermore, all peaks were more intense in the presence of NaOH, corroborating better solubilization yields compared with SCW (Fig. 1).

In hydrolysates obtained using SCW as solvent, most of peptides generated and solubilized possessed MW < 13,700 Da. However, and despite the prevalence of proteins and peptides in a similar MW range (MW < 13,700 Da), chromatograms of hydrolysates obtained using NaOH, also showed intense peaks corresponding to peptides with higher MW, as follows: 36,609 Da at 210 °C (Fig. 5C); 43,550 Da at 180° C (Fig. 5B), and 35,754 Da at 150 °C (Fig. 5A). Increasing temperature resulted in an improvement of lower MW peptide concentration—i.e., from 10 to 15 mAU at 150 °C to 20–25 mAU at 180 and 210 °C, corroborating higher DH. The patterns obtained also corroborated the protein quantification results described above and are in agreement with literature, in which enzymatic hydrolysis of blood followed by membrane fractionation resulted in hydrolysates mainly composed by peptides with MW < 13,700 Da (Araújo-Rodrigues et al., 2022).

Peptide chromatograms allowed to conclude that (i) increasing temperature and time of reaction leads to an increase of the DH (visible by the presence high concentrated peaks corresponding to low MW peptides), which was expected and in agreement with previous studies (Ahmed & Chun, 2018; Espinoza & Morawicki, 2012; Mekonnen et al., 2015), and (ii) the presence of NaOH in the reaction is important to solubilize higher amounts of protein (eventually higher MW proteins with poor solubility), leading to the presence of higher MW proteins and peptides (MW > 13,700 Da) in hydrolysates.

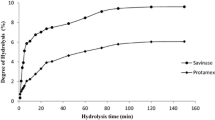

Antioxidant Activity (DPPH and ABTS Assays)

Proteins and peptides are reported as excellent antioxidant agents. However, different mechanisms of action to exert antioxidant activity are possible and it is advisable to combine different quantification methodologies to assess antioxidant activity of different ingredients. One of the mechanisms of such antioxidant properties is their ability for scavenging free radicals (Elias et al., 2008). Based on that, this study evaluated the antioxidant properties of produced hydrolysates through ABTS and DPPH methods. Hydrolysates used for antioxidant screening were diluted with dH2O in order to stay at a concentration of 5 g dry weight L−1.

Solvent and Temperature Effect

Results showed that all hydrolysates produced through either with SCW or with NaOH exhibited interesting antioxidant activities determined by the ABTS method, with percentages of ABTS inhibition ranging from 50 to 70% for a hydrolysate’s concentration of 5 g dry weight L−1 (Fig. 6). When considering SCW as solvent and a time of reaction of 60 min (Fig. 6), results showed that raising temperature both from 120 to 150 °C and from 180 to 210 °C, significantly (p < 0.05) increased the antioxidant activity of hydrolysates. However, though the general trend is the same, differences were not significant between the hydrolysates obtained at 150 °C and 180 °C.

Antioxidant activity of hydrolysates at 5 g dry weight L−1 by ABTS inhibition assay. Different letters mean significantly different (p < 0.05). Small letters analyzed effect of temperature within the same solvent (i.e., same solvent at different temperatures). Capital letters analyzed the effect of solvent in the same temperatures (i.e., same temperature with different solvents)

When using 0.1 mol L−1 NaOH as solvent, hydrolysates obtained at different temperatures did not differ in their activity, except for the ones obtained at 120 °C that significantly (p < 0.05) displayed lower activity (Fig. 6). This probably means that the peptides responsible for this antioxidant activity are already at their maximum concentration at temperatures of 150 °C, and further increases do not lead to further improvements. When comparing the different solvents, it was observed that hydrolysates obtained using 0.1 mol L−1 NaOH displayed better antioxidant activities (p < 0.05) than the ones obtained using only SCW, for all temperatures tested (Fig. 6). These results may be justified by the higher solubilization yields resulting in hydrolysates with higher protein concentration and, thus, higher peptides’ concentration (Fig. 1). Antioxidant activity in protein-based systems is usually related with the presence of bioactive peptides. The presence of NaOH increased the amount of peptides available, possibly also by generating higher amounts of bioactive peptides by hydrolytic reactions, thus leading to higher antioxidant activities. Furthermore, this is also consistent with the fact that hydrolysates obtained with only SCW as solvent at higher temperatures (i.e., 210 °C) are almost comparable (only 13% less) with those obtained when a small amount of NaOH was used.

DPPH was also tested but the antioxidant activity of hydrolysates was very low, ranging from 15 to 30% of DPPH reduction (Fig. 7). Previous report of Zheng et al. (2015) showed that DPPH has low reactivity towards peptides and it is very susceptible to interference, including pH, which could justify these results. In fact, according to the mentioned report, DPPH is not an appropriate method for screening antioxidant peptides because it only displayed reactivity towards Cys or Cys-dipeptides. Other peptides such as Tyr/Trp containing dipeptides with high reactivity towards ABTS•+ and peroxyl radicals are inert to the DPPH. However, blood hydrolysates produced through enzymatic hydrolysis (Wei & Chiang, 2009) displayed DPPH inhibition activities ranging from 12 to 65% of inhibition, depending on enzymes combination, supporting the ranges obtained in the present study. Moreover, Verma et al. (2019) evaluated the antioxidant activity of blood hydrolysates produced by enzymatic hydrolysis and, for the same conditions of hydrolysis, ABTS antiradicalar activity was higher than DPPH, being the range of DPPH inhibition between 20 and 55% against 40 to 82% of ABTS inhibition, supporting the results presented here and the differences seen in both assays.

Antioxidant activity of hydrolysates at 5 g dry weight L−1 by DPPH inhibition assay. Different letters mean significantly different (p < 0.05). Small letters analyzed the effect of temperature within the same solvent (i.e., same solvent at different temperatures). Capital letters analyzed the effect of solvent in the same temperatures (i.e., same temperature with different solvents)

Time and Temperature Effect

Regarding the time effect, using SCW as solvent, the hydrolysates were tested at 5 g dry weight L−1 by the ABTS assay. The results showed that 60 min of reaction resulted in highest antioxidant activities (p < 0.05) for all temperatures tested (Fig. 8). With these results, it was possible to conclude that antioxidant activity is not exclusively related with the DH, which increased with the time of reaction, leading to the formation of lower MW peptides. Higher times or temperatures may lead to different peptides and their corresponding concentrations (either by further hydrolyzing strong antioxidant peptides into peptides or AA with no or lower antioxidant activity; or by liberating more stronger antioxidant peptides). Previous studies already suggested that the antioxidant activity of bioactive peptides is more correlated with their AA sequence rather than DH (Ahmed & Chun, 2018; Chi et al., 2015). In fact, peptides with basic and/or hydrophobic AA residues are thought to have stronger antioxidant activities (Rajapakse et al., 2005; Saito et al., 2003; Verma et al., 2019).

Antioxidant activity of hydrolysates, obtained by SWH at different times of reaction, at 5 g dry weight L−1 by ABTS inhibition assay. Different letters mean significantly different (p < 0.05). Small letters analyzed the time effect within the same temperature (i.e., same temperature at different reaction times). Capital letters analyzed the temperature effect within the same reaction time (i.e., same reaction time with different temperatures)

Conclusions

This study showed that sub-critical solvent extraction (SSE/SWH) is an efficient process for protein extraction and hydrolysis from blood by-products, leading to a food or feed grade ingredient with high protein content. Though the process was already effective when using diluted alkali, SWH showed to be equally effective, thus removing the need for an extra chemical. Temperature and time of SSE/SWH reaction showed to influence DH and bioactivity of hydrolysates.

The hydrolysates produced demonstrated antioxidant activity, through scavenging of reactive oxygen species and this activity was probably related with production of bioactive peptides with MW up to 13,700 Da. It is known that reactive oxygen species are key factors for the development of several diseases, so these antioxidant properties can be appreciated for functional feed or food development, and also for bio-preservatives production by enhancing the storage stability of perishable foods.

Although the first steps towards new functional food development were made, more studies should be carried out in order to consider these hydrolysates for functional food development. Moreover, the selection of optimal conditions should take into account not only the bioactivity, protein content, and peptide profiles, but also the energy consumption of the process, as a way to make the technology as “green” and feasible as possible. Furthermore, all the processing (including the collection of the by-products) has to be made under food-grade conditions. Overall, in the tested experimental domain, the hydrolysis with water at 180 °C for 60 min showed to be a good compromise between a good antioxidant activity of the hydrolysates, interesting protein solubilization yields, energy consumption, and reduced or no chemicals use.

The results of this study show a possible path for the revalorization of porcine coagulated blood (PCB) with potential application in food, feed and aquaculture, adding economic value to a by-product from the meat industry (while also reducing the environmental burden of its discards), thus contributing to circular economy and zero waste.

Data Availability

All data analyzed during this study are included in this published article.

References

Ahmed, R., & Chun, B. S. (2018). Subcritical water hydrolysis for the production of bioactive peptides from tuna skin collagen. Journal of Supercritical Fluids, 141, 88–96. https://doi.org/10.1016/j.supflu.2018.03.006

Álvarez, C., Rendueles, M., & Díaz, M. (2012). Production of porcine hemoglobin peptides at moderate temperature and medium pressure under a nitrogen stream. Functional and antioxidant properties. Journal of Agricultural and Food Chemistry, 60(22), 5636–5643. https://doi.org/10.1021/jf300400k

Álvarez, C., Rendueles, M., & Díaz, M. (2013). Alkaline hydrolysis of porcine blood haemoglobin: Applications for peptide and amino acid production. Animal Production Science, 53(2), 121–128. https://doi.org/10.1071/AN12148

Álvarez, C., Tiwari, B. K., Rendueles, M., & Díaz, M. (2016). Use of response surface methodology to describe the effect of time and temperature on the production of decoloured, antioxidant and functional peptides from porcine haemoglobin by sub-critical water hydrolysis. LWT, 73, 280–289. https://doi.org/10.1016/j.lwt.2016.06.024

Álvarez-Viñas, M., Rodríguez-Seoane, P., Flórez-Fernández, N., Ma, & , Torres, D., Díaz-Reinoso, B., et al. (2021). Subcritical water for the extraction and hydrolysis of protein and other fractions in biorefineries from agro-food wastes and algae: A review. Food and Bioprocess Technology, 14, 373–387. https://doi.org/10.1007/s11947-020-02536-4/

AOAC Method 950.46. (2005). Official method of analysis. (Association of Officiating Analytical Chemists, Ed.) (18th Edition,.). Washington DC.

AOAC Method 981.10. (2005). Official methods of analysis. AOAC Official Methods of Analysis.

Araújo-Rodrigues, H., Coscueta, E. R., Pereira, M. F., Cunha, S. A., Almeida, A., Rosa, A., et al. (2022). Membrane fractionation of Cynara cardunculus swine blood hydrolysate: Ingredients of high nutritional and nutraceutical value. Food Research International, 158. https://doi.org/10.1016/j.foodres.2022.111549

Bah, C. S., Bekhit, A. E. D. A., Carne, A., & Mcconnell, M. A. (2016). Composition and biological activities of slaughterhouse blood from red deer, sheep, pig and cattle. Journal of the Science of Food and Agriculture, 96(1), 79–89. https://doi.org/10.1002/jsfa.7062

Bah, C. S. F., Bekhit, A. E. D. A., Carne, A., & Mcconnell, M. A. (2013). Slaughterhouse blood: An emerging source of bioactive compounds. Comprehensive Reviews in Food Science and Food Safety, 12(3), 314–331. https://doi.org/10.1111/1541-4337.12013

Bogialli, S., di Corcia, A., & Nazzari, M. (2007). Extraction procedures.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72.

Chi, C. F., Wang, B., Wang, Y. M., Zhang, B., & Deng, S. G. (2015). Isolation and characterization of three antioxidant peptides from protein hydrolysate of bluefin leatherjacket (Navodon septentrionalis) heads. Journal of Functional Foods, 12, 1–10. https://doi.org/10.1016/j.jff.2014.10.027

Compton, S. J., & Jones, C. G. (1985). Mechanism of dye response and interference in the Bradford protein assay.

da Silva, R. R. (2018). Enzymatic synthesis of protein hydrolysates from animal proteins: Exploring microbial peptidases. Frontiers in Microbiology. Frontiers Media S.A. https://doi.org/10.3389/fmicb.2018.00735

del Río, P. G., Gomes-Dias, J. S., Rocha, C. M. R., Romaní, A., Garrote, G., & Domingues, L. (2020). Recent trends on seaweed fractionation for liquid biofuels production. Bioresource Technology. Elsevier Ltd. https://doi.org/10.1016/j.biortech.2019.122613

Deleu, L. J., Lambrecht, M. A., van de Vondel, J., & Delcour, J. A. (2019, February 1). The impact of alkaline conditions on storage proteins of cereals and pseudo-cereals. Current Opinion in Food Science. Elsevier Ltd. https://doi.org/10.1016/j.cofs.2019.02.017

Domínguez-Perles, R., Teixeira, A. I., Rosa, E., & Barros, A. I. (2014). Assessment of (poly)phenols in grape (Vitis vinifera L.) stems by using food/pharma industry compatible solvents and Response Surface Methodology. Food Chemistry, 164, 339–346. https://doi.org/10.1016/j.foodchem.2014.05.020

Elias, R. J., Kellerby, S. S., & Decker, E. A. (2008). Antioxidant activity of proteins and peptides. Critical Reviews in Food Science and Nutrition, 48(5), 430–441. https://doi.org/10.1080/10408390701425615

Espinoza, A. D., & Morawicki, R. O. (2012). Effect of additives on subcritical water hydrolysis of whey protein isolate. Journal of Agricultural and Food Chemistry, 60(20), 5250–5256. https://doi.org/10.1021/jf300581r

Esteban, M. B., García, A. J., Ramos, P., & Márquez, M. C. (2010). Sub-critical water hydrolysis of hog hair for amino acid production. Bioresource Technology, 101(7), 2472–2476. https://doi.org/10.1016/j.biortech.2009.11.054

European Parliament and Council. (2009). Regulation (EC) No. 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No. 1774/2002 (Animal by-products Regulation).

Friedman, M., Gumbmann, M. R., & Masters, P. M. (1984). 8 protein-alkali reactions: Chemistry, toxicology, and nutritional consequences abstract.

Gagaoua, M. (2018). Aqueous methods for extraction/recovery of macromolecules from microorganisms of atypical environments: A focus on three phase partitioning. In Methods in Microbiology (Vol. 45, pp. 203–242). Academic Press Inc. https://doi.org/10.1016/bs.mim.2018.07.007

Hai, T. D. (2020). Hydrolysis methods for protein extraction from seafood. American Journal of Biomedical Science & Research, 11(2), 222–224. https://doi.org/10.34297/ajbsr.2020.11.001630

Henchion, M., Hayes, M., Mullen, A. M., Fenelon, M., & Tiwari, B. (2017). Future protein supply and demand: Strategies and factors influencing a sustainable equilibrium. Foods, 6(7), 1–21. https://doi.org/10.3390/foods6070053

Hou, Y., Wu, Z., Dai, Z., Wang, G., & Wu, G. (2017). Protein hydrolysates in animal nutrition: Industrial production, bioactive peptides, and functional significance. Journal of Animal Science and Biotechnology. BioMed Central Ltd. https://doi.org/10.1186/s40104-017-0153-9

Hwang, Y. H., Cho, H. Y., Kim, K. R., Lee, S. H., Choi, M. J., & Shin, J. K. (2015). Hydrolysis of isolate soybean protein using subcritical water. Korean Journal of Food Science and Technology, 47(6), 772–778. https://doi.org/10.9721/KJFST.2015.47.6.772

Hyun, C.-K., & Shin, H.-K. (1998). Utilization of bovine blood plasma obtained from a slaughterhouse for economic production of probiotics. Journal of Fermentation and Bioengineerinc, 86.

King, J. W. (2000). King 2000. Food Science and Technology Today, 14(4), 186–191.

Jin, S. K., Choi, J. S., & Yim, D. G. (2020). Hydrolysis conditions of porcine blood proteins and antimicrobial effects of their hydrolysates. Food Science of Animal Resources, 40(2), 172–182. https://doi.org/10.5851/kosfa.2020.e2

Kang, K., Quitain, A. T., Daimon, H., Noda, R., Goto, N., Hu, H.-Y., & Fujie, K. (2001). Optimization of amino acids production from waste fish entrails by hydrolysis in sub-and supercritical water. The Canadian Journal of Chemical Engineering, 79.

Kruger, N. J. (2009). The Bradford method for protein quantitation.

Lamoolphak, W., De-Eknamkul, W., & Shotipruk, A. (2008). Hydrothermal production and characterization of protein and amino acids from silk waste. Bioresource Technology, 99(16), 7678–7685. https://doi.org/10.1016/j.biortech.2008.01.072

Lee, S. H., Song, K., & bin. (2009). Purification of an iron-binding nona-peptide from hydrolysates of porcine blood plasma protein. Process Biochemistry, 44(3), 378–381. https://doi.org/10.1016/j.procbio.2008.12.001

Li, Q., Liu, J., Cao, L., Zhang, L., Bredie, W. L. P., Otte, J., & Lametsch, R. (2022). Effects of γ-glutamylated hydrolysates from porcine hemoglobin and meat on Kokumi enhancement and oxidative stability of emulsion-type sausages. Food and Bioprocess Technology, 15(8), 1851–1865. https://doi.org/10.1007/s11947-022-02851-y

Mæhre, H. K., Dalheim, L., Edvinsen, G. K., Elvevoll, E. O., & Jensen, I. J. (2018). Protein determination—method matters. Foods, 7(1). https://doi.org/10.3390/foods7010005

Marcet, I., Álvarez, C., Paredes, B., & Díaz, M. (2016). The use of sub-critical water hydrolysis for the recovery of peptides and free amino acids from food processing wastes. Review of sources and main parameters. Waste Management. Elsevier Ltd. https://doi.org/10.1016/j.wasman.2016.01.009

Mekonnen, T. H., Mussone, P. G., El-Thaher, N., Choi, P., & Bressler, D. C. (2015). Subcritical hydrolysis and characterization of waste proteinaceous biomass for value added applications. Journal of Chemical Technology and Biotechnology, 90(3), 476–483. https://doi.org/10.1002/jctb.4333

Moreschi, S. R. M., Petenate, A. J., & Meireles, M. A. A. (2004). Hydrolysis of Ginger bagasse starch in subcritical water and carbon dioxide. Journal of Agricultural and Food Chemistry, 52(6), 1753–1758. https://doi.org/10.1021/jf035347a

Mottet, A., de Haan, C., Falcucci, A., Tempio, G., Opio, C., & Gerber, P. (2017). Livestock: On our plates or eating at our table? A new analysis of the feed/food debate. Global Food Security, 14, 1–8. https://doi.org/10.1016/j.gfs.2017.01.001

Rajapakse, N., Mendis, E., Byun, H. G., & Kim, S. K. (2005). Purification and in vitro antioxidative effects of giant squid muscle peptides on free radical-mediated oxidative systems. Journal of Nutritional Biochemistry, 16(9), 562–569. https://doi.org/10.1016/j.jnutbio.2005.02.005

Rogalinski, T., Herrmann, S., & Brunner, G. (2005). Production of amino acids from bovine serum albumin by continuous sub-critical water hydrolysis. Journal of Supercritical Fluids, 36(1), 49–58. https://doi.org/10.1016/j.supflu.2005.03.001

Saito, K., Jin, D. H., Ogawa, T., Muramoto, K., Hatakeyama, E., Yasuhara, T., & Nokihara, K. (2003). Antioxidative properties of tripeptide libraries prepared by the combinatorial chemistry. Journal of Agricultural and Food Chemistry, 51(12), 3668–3674. https://doi.org/10.1021/jf021191n

Samsalee, N., & Sothornvit, R. (2020). Characterization of food application and quality of porcine plasma protein–based films incorporated with chitosan or encapsulated turmeric oil. Food and Bioprocess Technology, 13(3), 488–500. https://doi.org/10.1007/s11947-020-02411-2

Sedmakand, J. J., & Grossberg, S. E. (1977). A rapid, sensitive, and versatile assay for protein using Coomassie brilliant blue G250. Analytical Biochemistry, 79.

Sereewatthanawut, I., Prapintip, S., Watchiraruji, K., Goto, M., Sasaki, M., & Shotipruk, A. (2008). Extraction of protein and amino acids from deoiled rice bran by subcritical water hydrolysis. Bioresource Technology, 99(3), 555–561. https://doi.org/10.1016/j.biortech.2006.12.030

Sorapukdee, S., & Narunatsopanon, S. (2017). Comparative study on compositions and functional properties of porcine, chicken and duck blood. Korean Journal for Food Science of Animal Resources, 37(2), 228–241. https://doi.org/10.5851/kosfa.2017.37.2.228

Tavakoli, O., & Yoshida, H. (2006). Conversion of scallop viscera wastes to valuable compounds using sub-critical water. Green Chemistry, 8(1), 100–106. https://doi.org/10.1039/b507441j

Teixeira-Guedes, C. I., Oppolzer, D., Barros, A. I., & Pereira-Wilson, C. (2019). Impact of cooking method on phenolic composition and antioxidant potential of four varieties of Phaseolus vulgaris L. and Glycine max L. LWT, 103, 238–246. https://doi.org/10.1016/j.lwt.2019.01.010

Verma, A. K., Chatli, M. K., Kumar, P., & Mehta, N. (2019). Antioxidant and antimicrobial efficacy of peptidic hydrolysate obtained from porcine blood. Agricultural Research, 8(1), 116–124. https://doi.org/10.1007/s40003-018-0350-6

Voss, G. B., Osorio, H., Valente, L. M. P., & Pintado, M. E. (2019). Impact of thermal treatment and hydrolysis by Alcalase and Cynara cardunculus enzymes on the functional and nutritional value of Okara. Process Biochemistry, 83, 137–147. https://doi.org/10.1016/j.procbio.2019.05.010

Wei, J. T., & Chiang, B. H. (2009). Bioactive peptide production by hydrolysis of porcine blood proteins in a continuous enzymatic membrane reactor. Journal of the Science of Food and Agriculture, 89(3), 372–378. https://doi.org/10.1002/jsfa.3451

Zampiga, M., Calini, F., & Sirri, F. (2021). Importance of feed efficiency for sustainable intensification of chicken meat production: Implications and role for amino acids, feed enzymes and organic trace minerals. World’s Poultry Science Journal, 77(3), 639–659. https://doi.org/10.1080/00439339.2021.1959277

Zheng, L., Lin, L., Su, G., Zhao, Q., & Zhao, M. (2015). Pitfalls of using 1,1-diphenyl-2-picrylhydrazyl (DPPH) assay to assess the radical scavenging activity of peptides: Its susceptibility to interference and low reactivity towards peptides. Food Research International, 76, 359–365. https://doi.org/10.1016/j.foodres.2015.06.045

Zheng, P., Hao, G., Weng, W., & Ren, H. (2019). Antioxidant activities of hydrolysates from abalone viscera using subcritical water-assisted enzymatic hydrolysis. Food and Bioprocess Technology, 12(6), 910–918. https://doi.org/10.1007/s11947-019-02270-6

Zhu, G. Y., Zhu, X., Wan, X. L., Fan, Q., Ma, Y. H., Qian, J., et al. (2010). Hydrolysis technology and kinetics of poultry waste to produce amino acids in subcritical water. Journal of Analytical and Applied Pyrolysis, 88(2), 187–191. https://doi.org/10.1016/j.jaap.2010.04.005

Zhu, X., Chao, Z., Liang, Z., & Cheng, H. (2008). Amino acids production from fish proteins hydrolysis in subcritical water. Chinese Journal of Chemical Engineering, 16.

Zielinski, A. A. F., Sanchez-Camargo, A. del P., Benvenutti, L., Ferro, D. M., Dias, J. L., & Ferreira, S. R. S. (2021). High-pressure fluid technologies: Recent approaches to the production of natural pigments for food and pharmaceutical applications. Trends in Food Science and Technology. Elsevier Ltd. https://doi.org/10.1016/j.tifs.2021.11.008

Funding

Open access funding provided by FCT|FCCN (b-on). This work was financed by the MobFood Mobilizing Project—“Mobilizing Scientific and Technological Knowledge in Response to Agri-Food Market Challenges” (POCI-01–0247-FEDER-024524•LISBOA-01–0247-FEDER-024524), financed by PORTUGAL2020, Lisb@a2020, COMPETE 2020 and the European Union, and by the project BIOECONORTE—Water and nutrients management based on BIOrefinery and circular ECOnomy towards a sustainable agri-food system of the NORTE of Portugal (ref. NORTE-01–0145-FEDER-000070; financed by NORTE2020, Portugal 2020 and ESIF—European Structural and Investment Funds). This study was also supported by the Portuguese Foundation for Science and Technology (FCT) under the scope of both the strategic funding of UIDB/04469/2020 unit and the FCT project UID/Multi/50016/2020. Ricardo N. Pereira acknowledges FCT for its Assistant Research program under the scope of Scientific Stimulus Employment with reference CEECIND/02903/2017.

Author information

Authors and Affiliations

Contributions

Bianca Marques wrote the main manuscript draft. All authors wrote, edited and reviewed the manuscript, and discussed the results. Bianca Marques, Rafaela Nunes, and Helena Araújo-Rodrigues performed the main experimental work and data analysis. Cristina Rocha, Ricardo Pereira, Manuela Pintado, and José Teixeira were responsible for the work conceptualization, methodology, and experimental design. Cristina Rocha, Manuela Pintado, and José Teixeira supervised the work. José Teixeira, Manuela Pintado, Cristina Rocha, and Ricardo Pereira were responsible for the funding and resources.

Corresponding author

Ethics declarations

Conflict of Interest

J. A. Teixeira is a member of the Editorial Board of Food and Bioprocess Technology. All other authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Marques, B., Nunes, R., Araújo-Rodrigues, H. et al. Solubilization and Hydrolysis of Porcine Coagulated Blood Protein Using Sub-Critical Solvent Extraction. Food Bioprocess Technol 17, 123–137 (2024). https://doi.org/10.1007/s11947-023-03111-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03111-3