Abstract

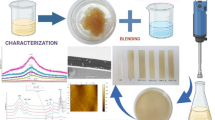

A novel, flexible sheet-like food formed by the high methoxyl pectin–sugar–acid gelation during drying of apple puree was investigated to characterize drying-related properties. Product volume was reduced by 68% over the process, and this shrinkage was successfully modeled by assuming the volume reduction equal to the volume of water evaporated. The sorption isotherm at 25 °C was determined, and a new expression for the moisture content, W, as a function of water activity, a w, of the type \(W\,{\text{ = }}\,{\text{C}}_{\text{1}} \,{\text{exp}}\,\left( {{\text{C}}_{\text{2}} \,a_w^{{\text{C}}3} } \right)\) resulted as the most accurate for this J-shaped isotherm. The drying kinetics was studied at 50, 60, and 80 °C in a tray dryer. No constant drying rate period was found, and the drying curve was divided in high- and low-moisture zones. For high moistures, an internal–external mixed control diffusive model coupling mass and heat transfer was applied to obtain a mass transfer Biot number of 2.1. In the low-moisture zone, a diffusive, isothermal drying model for strict internal control was utilized. Diffusivities varied around 1 × 10–9 m2/s for high moistures and were about ten times lower at low moistures, although the activation energies were comparable (15,259 and 16,800 J/mol, respectively). The drying time at 60 °C was 6.67 h. The product scored four points out of five in a sensory evaluation of general acceptability.

Similar content being viewed by others

Abbreviations

- A :

-

mass transfer area for evaporation (m2)

- a w :

-

water activity, decimal

- A h and B h :

-

fitting parameters of the Halsey model

- A o and B o :

-

fitting parameters of the Oswin model

- a, b, c, and d :

-

coefficients of the third degree polynomials W = f(t)

- Bi:

-

mass transfer Biot number

- C p :

-

specific heat of apples (J kg−1 K−1)

- C :

-

constant of the GAB model

- C1, C2, C3 :

-

parameters of the new sorption model

- D :

-

effective diffusion coefficient of water (m2/s)

- d :

-

average laminate thickness (m)

- D 0 :

-

Arrhenius preexponential factor (m2/s)

- E a :

-

activation energy (J/mol)

- f :

-

multiplier of the preliminary Arrhenius preexponential factor

- h :

-

heat transfer coefficient (W/°C m2)

- h a :

-

air absolute humidity (kg vapor/kg dry air)

- h r :

-

air relative humidity (decimal)

- k :

-

constant of the GAB model

- L wd :

-

product heat of desorption (J/kg)

- L w :

-

heat of vaporization of water (J/kg)

- m :

-

product mass at any time (kg)

- m 0 :

-

initial product mass (kg)

- m d :

-

product dry matter (kg)

- m wev :

-

mass of water evaporated (kg)

- MSS:

-

sum of squares of the deviation

- M 1n, M 2n, M 3n and M 4n :

-

values of parameters of Eq. 15

- r 2 :

-

coefficient of determination

- R :

-

universal gas constant 8.314 J mol−1 K−1

- t :

-

time (s)

- T a :

-

air temperature (°C)

- T 0 :

-

product temperature at t = 0 (°C)

- T :

-

product temperature (°C)

- V :

-

product volume at W (m3)

- V 0 :

-

initial product volume (m3)

- V d :

-

dry matter volume (m3)

- V wev :

-

volume of water evaporated (m3)

- W :

-

moisture content (dec., d.b.)

- W :

-

product average moisture content (dec., d.b.)

- W e :

-

equilibrium moisture content (dec., d.b.)

- W 0 :

-

initial moisture content (dec., d.b.)

- W m :

-

monolayer moisture content of the GAB model (dec., d.b.)

- W ad :

-

dimensionless moisture content

- β n :

-

roots of the equation β n tan β n − Bi = 0

- ρ :

-

product density (kg/m3)

- ρ d :

-

dry matter density (kg/m3)

- ρ w :

-

liquid water density (kg/m3)

- Subscripts :

-

- hm :

-

high-moisture zone

- lm :

-

low-moisture zone

References

Andrés, S. C., Giannuzzi, L., & Zaritzky, N. E. (2002). Quality parameters of packaged refrigerated apple cubes in orange juice. Lebensmittel-Wissenschaft und-Technologie, 35(8), 670–679.

AOAC (1984). Official methods of analysis (14st ed.). Washington, DC, USA: Association of Official Analytical Chemists.

Barbosa-Cánovas, G. V., & Vega-Mercado, H. (1996). Dehydration of foods. New York, USA: Chapman and Hall.

Bhandari, B. R., & Howes, T. (1999). Implication of glass transition for the drying and stability of dried foods. Journal of Food Engineering, 40(1–2), 71–79.

Bruce, D. M. (1985). Exposed-layer barley drying: three models fitted to new data up to 150°C. Journal of Agriculture Engineering Research, 32, 337–347.

CAA (2004). Código Alimentario Argentino, Cap. XI, Alimentos vegetales [Argentine Food Code, Ch. XI, Plant Foods]. Administración Nacional de Medicamentos, Alimentos y Tecnología Médica. Ministerio de Salud y Ambiente de la Nación Argentina. Retrieved September 01, 2007 frm http://www.anmat.gov.ar/codigoa/caa1.htm.

Constantinides, A., & Mostoufi, N. (1999). Numerical methods for chemical engineers with MATLAB applications. New Jersey, USA: Prentice Hall.

Copley, M. J., & Van Arsdel, W. (1973). Food dehydration, Vol. II. Products and technology. Westport, CT, USA: The AVI Publishing.

Crank, J. (1975). The mathematics of diffusion (2nd ed.). Oxford: Oxford University Press.

Crapiste, G. H., & Rotstein, E. (1997). Design and performance evaluation of dryers. In K. J. Valentas, E. Rotstein, & R. P. Singh (Eds.) Handbook of food engineering practice, Ch. 4 (pp. 125–165). Boca Raton, USA: CRC Press.

Crapiste, G. H., Whitaker, S., & Rotstein, E. (1988a). Drying of cellular material—I. A mass transfer theory. Chemical Engineering Science, 43(11), 2919–2928.

Crapiste, G. H., Whitaker, S., & Rotstein, E. (1988b). Drying of cellular material—II. Experimental and numerical results. Chemical Engineering Science, 43(11), 2929–2936.

Geankoplis, C. J. (1993). Transport processes and unit operations (3rd ed.). New Jersey, USA: Prentice Hall.

Gekas, V., & Lamberg, I. (1991). Determination of diffusion coefficients in volume-changing systems—Application in the case of potato drying. Journal of Food Engineering, 14(4), 317–326.

Giner, S. A., & Gely, M. C. (2005). Sorptional parameters of sunflower seeds of use in drying and storage stability studies. Biosystems Engineering, 92(2), 217–227.

Greensmith, M. (1998). Practical dehydration (2nd ed.). England: Woodhead.

Gregg, S. J., & Sing, K. S. W. (1967). Adsorption, surface area and porosity. London: Academic.

Kaya, S., & Kahyaoglu, T. (2005). Thermodynamic properties and sorption equilibrium of pestil (grape leather). Journal of Food Engineering, 71(2), 200–207.

Kayman-Ertekin, F., & Gedik, A. (2004). Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. Lebensmittel-Wissenschaft und Technology, 37, 429–438.

Kechaou, N., Roques, M. A., & Lambert, J. F. (1987). Diffusion in shrinking media: The case of drying of gels. In Physical properties of foods-2, Part. 1: Diffusion, paper 4 (pp. 55–60). London: Elsevier Applied Science.

Krokida, M. K., Foundoukidis, E., & Maroulis, Z. (2004). Drying constant: Literature data compilation for foodstuffs. Journal of Food Engineering, 61(3), 321–330.

Krokida, M. K., & Marinos-Kouris, D. (2003). Rehydration kinetics of dehydrated products. Journal of Food Engineering, 57(1), 1–7.

Labuza, T. P. (1984). Practical aspects of isotherm measurement and use. St. Paul, MN: American Association of Cereal Chemists.

Maskan, A., Kaya, S., & Maskan, M. (2002). Hot air and sun drying of grape leather (pestil). Journal of Food Engineering, 54(1), 81–88.

Mayor, L., & Sereno, A. M. (2004). Modelling shrinkage during convective drying of food materials: a review. Journal of Food Engineering, 61(3), 373–386.

Mohsenin, N. M. (1980). Thermal properties of food and agricultural materials. London: Gordon and Breach.

Moreno Semhan, D., Albertario, E., & Giner, S. A. (2004). Dehydration of apple and tomato purees into flexible laminates. Heat and mass transfer studies and product characteristics. Drying 2004, Proceedings of the 14th International Drying Symposium (IDS 2004), Sao Paulo, Brazil, vol. C, pp. 1751–1758.

Mulet, A. (1994). Drying modelling and water diffusivity in carrots and potatoes. Journal of Food Engineering, 22(1–4), 329–348.

Nguyen, M. H., & Price, W. E. (2007). Air-drying of banana: Influence of experimental parameters, slab thickness, banana maturity and harvesting season. Journal of Food Engineering, 79(1), 200–207.

Ochoa, M. R., Kesseler, A. G., Pirone, B. N., Márquez, C. A., & De Michelis, A. (2002). Shrinkage during convective air drying of whole rose hip (Rosa rubiginosa L.) fruits. Lebensmittel-Wissenschaft und-Technologie, 35(5), 400–406.

Pezzutti, A., & Crapiste, G. H. (1997). Sorptional equilibrium and drying characteristics of garlic. Journal of Food Engineering, 31(1), 113–123.

Ratti, C. (1994). Shrinkage during drying of foodstuffs. Journal of Food Engineering, 23(1), 91–105.

Ratti, C. (2001). Hot air and freeze-drying of high value foods: A review. Journal of Food Engineering, 49(4), 311–319.

Ratti, C., & Crapiste, G. H. (1995). Determination of heat transfer coefficients during drying of foodstuffs. Journal of Food Process Engineering, 18, 41–53.

Rolin, C., & De Vries, J. (1990). Pectin. In P. Harris (Ed.) Food gels (pp. 401–434). Amsterdam: Elsevier.

Roos, Y. H. (1995). Phase transitions in foods. San Diego: Academic.

Roques, M. A. (2005). Conference report of the 14th International Drying Symposium (IDS 2004). Drying Technology, 23(1 & 2), 407–411.

Systat (1990) Systat 5.02 for Windows, Systat, Inc., Evanston, IL, USA, 60201.

Vagenas, G. K., & Marinos-Kouris, D. (1990). An analysis of mass transfer in air-drying of foods. Drying Technology, 8, 323–342.

Wolf, I. D., Labuza, T. P., Olson, W. W., & Schafer, W. (1990). Drying foods at home. Communication and educational technology services. USA: University of Minnesota.

Zogzas, N. P., Maroulis, Z. B., & Marinos-Kouris, D. (1996). Moisture diffusivity data compilation in foodstuffs. Drying Technology, 14(10), 2225–2254.

Acknowledgment

The authors thank Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT), Argentina, for providing funding to Project PICT 2002 09-12196 and to the Comisión de Investigaciones Científicas, CICPBA, CONICET, and Universidad Nacional de La Plata from Argentina for their permanent support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leiva Díaz, E., Giannuzzi, L. & Giner, S.A. Apple Pectic Gel Produced by Dehydration. Food Bioprocess Technol 2, 194–207 (2009). https://doi.org/10.1007/s11947-007-0035-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-007-0035-9