Abstract

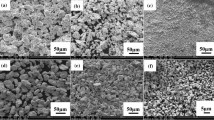

FeCoCrNi+FeCoCrNiAl-laminated high-entropy alloy (HEA) was manufactured by laser melting deposition. The two adjacent HEA layers consisted of columnar grains with the orientation <001>//BD (building direction). However, the grains in the FeCoCrNiAl HEA were smaller than those in the FeCoCrNi HEA. The microstructure of the deposited HEA was dominated by the FCC phase, together with a low content of the BCC phase. After tensile tests, the number of columnar grains with the <011>//BD orientation increased appreciably. The difference in grain size, orientation of grain growth, physical properties of the two-phase structure, and the macroscopic interface between the adjacent HEAs gave rise to the concentration of dislocations and hindered plastic deformation during the tensile testing. As a result, the strength and toughness of the laminated HEA were effectively improved. However, the existence of columnar grains in the laminated HEA initiates and propagates cracking in the weak regions near the grain boundaries under tensile forces.

Similar content being viewed by others

Data Availability

The parameters database, data and figures in this study can be provided for reasonable requests or future cooperation. Please address requests to the correspondence author, Prof. Jian Han.

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299. https://doi.org/10.1002/adem.200300567 (2004).

J.W. Bae, J.M. Park, J. Moon, W.M. Choi, B.J. Lee, and H.S. Kim, J. Alloy. Compd. 781, 75. https://doi.org/10.1016/j.jallcom.2018.12.040 (2019).

E.P. George, W.A. Curtin, and C.C. Tasan, Acta. Mater. 188, 435. https://doi.org/10.1016/j.actamat.2019.12.015 (2020).

S.L. Wei, S.J. Kim, J.Y. Kang, Y. Zhang, Y.J. Zhang, T. Furuhara, E.S. Park, and C.C. Tasan, Nat. Mater. 19, 1175. https://doi.org/10.1038/s41563-020-0750-4 (2020).

Y. Fu, J. Li, H. Luo, C.W. Cu, and X.G. Li, J. Mater. Sci. Technol. 80, 217. https://doi.org/10.1016/j.jmst.2020.11.044 (2021).

C.Y. Lu, L.L. Niu, N.J. Chen, K. Jin, T.N. Yang, P.Y. Xiu, Y.W. Zhang, F. Gao, H.B. Bei, S. Shi, M.R. He, I.M. Robertson, W.J. Weber, and L.M. Wang, Nat. Commun. 7, 13564. https://doi.org/10.1038/ncomms13564 (2016).

L. Liu, Q. Yu, Z. Wang, J. Ell, M.X. Huang, and R.O. Ritchie, Science. 368, 1347. https://doi.org/10.1126/science.aba9413 (2020).

T. Yang, Y.L. Zhao, W.P. Li, C.Y. Yu, J.H. Luan, D.Y. Lin, L. Fan, Z.B. Jiao, W.H. Liu, X.J. Liu, J.J. Kai, J.C. Huang, and C.T. Liu, Science 369, 427. https://doi.org/10.1126/science.aal5166 (2020).

J. Hu, Y.N. Shi, X. Sauvage, G. Sha, and K. Lu, Science. 355, 1292. https://doi.org/10.1126/science.aal5166 (2017).

T. Wang, S. Li, H. Niu, C. Luo, X.B. Ma, Y.M. Liu, J.C. Han, and M.U. Bashir, J. Mater. Res. Technol. 9, 5840. https://doi.org/10.1016/j.jmrt.2020.03.111 (2020).

D.Y. Li, G.H. Fan, X.X. Huang, D.J. Jensen, K.S. Miao, C. Xu, L. Geng, Y.B. Zhang, and T.B. Yu, Acta. Mater. 206, 116627. https://doi.org/10.1016/j.actamat.2021.116627 (2021).

S.Q. Yuan, S.Y. Li, J.H. Zhu, and Y.L. Tang, Compos Part. B-Eng. 219, 108903. https://doi.org/10.1016/j.compositesb.2021.108903 (2021).

J.J. Lewandowski, M. Seifi, Annu. Rev. Mater. Res. 46, 14.1. https://doi.org/10.1146/annurev-matsci-070115-032024 (2016).

C.L. Tan, Y.X. Chew, R.X. Duan, F. Weng, S. Sui, F.L. Ng, Z.L. Du, and G.J. Bi, Mater. Res. Lett. 9, 291. https://doi.org/10.1080/21663831.2021.1904299 (2021).

P. Kürnsteiner, M.B. Wilms, A. Weisheit, B. Gault, E.A. Jägle, and D. Raabe, Nature 582, 515. https://doi.org/10.1038/s41586-020-2409-3 (2020).

C.J. Han, Q.H. Fang, Y.S. Shi, S.B. Tor, C.K. Chua, and K. Zhou, Adv. Mater. 32, 1903855. https://doi.org/10.1002/adma.201903855 (2020).

A.O. Moghaddam, N.A. Shaburova, M.N. Samodurova, A. Abdollahzadeh, and E.A. Trofimov, J. Mater. Sci. Technol. 77, 131. https://doi.org/10.1016/j.jmst.2020.11.029 (2021).

S. Guan, D. Wan, K. Solberg, F. Berto, T. Welo, T.M. Yue, and K.C. Chan, Scr. Mater. 183, 133. https://doi.org/10.1016/j.scriptamat.2020.03.032 (2020).

H. Dobbelstein, E.L. Gurevich, E.P. George, A. Ostendorf, and G. Laplanche, Addit. Manuf. 25, 252. https://doi.org/10.1016/j.addma.2018.10.042 (2019).

Y.C. Cai, L.S. Zhu, Y. Cui, and J. Han, Mater Lett. 289, 129445. https://doi.org/10.1016/j.matlet.2021.129445 (2021).

Y.C. Cai, X.P. Li, H.B. Xia, Y. Cui, S.M. Manladan, L.S. Zhu, M.D. Shan, D. Sun, T. Wang, X. Lv, and J. Han, J Manuf. Process. 72, 294. https://doi.org/10.1016/j.jmapro.2021.10.022 (2021).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, and Z.P. Lu, Acta. Mater. 62, 105. https://doi.org/10.1016/j.actamat.2013.09.037 (2014).

M.X. Zhang, P. Kelly, M. Easton, and J. Taylor, Acta. Mater. 53, 1427. https://doi.org/10.1016/j.actamat.2004.11.037 (2005).

M.A. Easton, and D.H. StJohn, Acta. Mater. 49, 1867. https://doi.org/10.1016/S1359-6454(00)00368-2 (2001).

W. Wang, P.D. Lee, and M. McLean, Acta. Mater. 51, 2971. https://doi.org/10.1016/S1359-6454(03)00110-1 (2003).

J. Wang, Z.X. Pan, Y.F. Wang, L. Wang, L.H. Su, D. Cuiuri, Y.H. Zhao, and H.J. Li, Add Manuf. 34, 101240. https://doi.org/10.1016/j.addma.2020.101240 (2020).

G.M. Zheng, B. Tang, Q. Zhou, X.N. Mao, and R. Dang, Metals. 10, 121. https://doi.org/10.3390/met10010121 (2020).

Z.F. Yan, D.H. Wang, and X.L. He, Mat. Sci. Eng. A. 723, 212. https://doi.org/10.1016/j.msea.2018.03.023 (2018).

Y.C. Cai, L.S. Zhu, Y. Cui, K.P. Geng, S.M. Manladan, Z. Luo, and J. Han, Mater. Charact. 159, 110037. https://doi.org/10.1016/j.matchar.2019.110037 (2020).

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner, Metall. Trans. A. 20, 1125. https://doi.org/10.1007/BF02650147 (1989).

M. Rappaz, and C.A. Gandin, Acta. Metall. Mater. 41, 345. https://doi.org/10.1016/0956-7151(93)90065-Z (1993).

M.S. Pham, B. Dovgyy, P.A. Hooper, C.M. Gourlay, and A. Piglione, Nat. Commun. 11, 749. https://doi.org/10.1038/s41467-020-14453-3 (2020).

Y.K. Shon, S.S. Joshi, S. Katakam, R.S. Rajamure, and N.B. Dahotre, Mater. Lett. 142, 122. https://doi.org/10.1016/j.matlet.2014.11.161 (2015).

C. Li, J.C. Li, M. Zhao, and Q. Jiang, J Alloy Compd. 504, S515. https://doi.org/10.1016/j.jallcom.2010.03.111 (2010).

Acknowledgements

The authors are grateful for the relevant device support from Tianjin Sino-German University of Applied Sciences. This research was supported by National Nature Science Foundation of Tianjin (Grant 19JCZDJC39000).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cai, Y., Cui, Y., Manladan, S.M. et al. Mechanism for the Improvement of the Mechanical Properties of FeCoCrNi+FeCoCrNiAl-Laminated HEA Fabricated by Laser Melting Deposition. JOM 74, 2860–2870 (2022). https://doi.org/10.1007/s11837-022-05263-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05263-7