Abstract

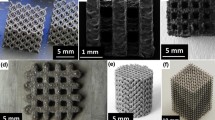

Tantalum is a refractory metal with a melting point of 2996°C but it offers outstanding biocompatibility for bone implant applications. In this study, the selective electron beam melting (SEBM) process was used for the first time to fabricate both dense and fine lattice tantalum structures. The use of 90-ppm-oxygen Ta powder for SEBM ensured excellent ductility of the as-printed fine Ta lattice implants with strut diameter of just 350 μm. The as-printed dense Ta samples (99.90%) achieved tensile ductility of 45% compared with the minimum requirement of 25% by ISO 13782 and the reported 2% fabricated by SLM using 1800-ppm-oxygen Ta powder. Since 2016, 27 clinical applications have been achieved in China using the custom-designed and SEBM-printed Ta implants by the authors of this study. All these Ta implants (mostly Ta lattice structures) have performed satisfactorily in patients’ bodies so far. Three selected clinical applications, Ta lattice hip, fibula and femur implants, are briefly discussed in this article.

Similar content being viewed by others

References

V. Livescu, C.M. Knapp, G.T. Gray, R.M. Martinez, B.M. Morrow, and B.G. Ndefru, Materialia 1, 15 (2018).

V.K. Balla, S. Bodhak, S. Bose, and A. Bandyopadhyay, Acta Biomater. 6, 3349 (2010).

L. Thijs, M.L. Montero Sistiaga, R. Wauthle, Q. Xie, J.-P. Kruth, and J. Van Humbeeck, Acta Mater. 61, 4657 (2013).

T. Kokubo, H.-M. Kim, and M. Kawashita, Biomaterials 24, 2161 (2003).

S.A. Hacking, J.D. Bobyn, K. Toh, M. Tanzer, and J.J. Krygier, J. Biomed. Mater. Res. 52, 631 (2000).

J.D. Bobyn, G.J. Stackpool, S.A. Hacking, M. Tanzer, and J.J. Krygier, J. Bone Jt. Surg. (Br) 81B, 907 (1999).

H. Matsuno, A. Yokoyama, F. Watari, U. Motohiro, and T. Kawasaki, Biomaterials 22, 1253 (2001).

L. Zhou, T. Yuan, R. Li, J. Tang, G. Wang, and K. Guo, Mater. Sci. Eng. A 707, 443 (2017).

H.R. Ogden, A.G. Imgram, and E.S. Bartlett, Can. Metall. Q. 1, 13 (1962).

B.R. Levine, S. Sporer, R.A. Poggie, C.J. Della Valle, and J.J. Jacobs, Biomaterials 27, 4671 (2006).

X.Z. Zhang, M. Leary, H.P. Tang, T. Song, and M. Qian, Curr. Opin. Solid State Mater. Sci. 22, 75 (2018).

H.P. Tang, M. Qian, N. Liu, X.Z. Zhang, G.Y. Yang, and J. Wang, JOM 67, 555 (2015).

ISO 13782, Implants for Surgery—Metallic Materials—Unalloyed Tantalum for Surgical Implant Applications, (International Organization for Standardization, Geneva, Switzerland, 1996).

J. Black, Clin. Mater. 16, 167 (1994).

L.E. Murr, S.M. Gaytan, F. Medina, H. Lopez, E. Martinez, B.I. Machado, D.H. Hernandez, L. Martinez, M.I. Lopez, R.B. Wicker, and J. Bracke, Philos. Trans. R. Soc. A 368, 1999 (2010).

ASTM E8/E8M-16a, Standard Test Methods for Tension Testing of Metallic Materials, (ASTM, West Conshohocken, PA, 2016).

ISO 13314, Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals (International Organization for Standardization, Geneva, Switzerland, 2011(E)).

YB/T 5349, Metallic Materials—Determination of Bending Mechanical Properties (Standard of China Ferrous Metallurgy, Beijing, China, 2014).

M. Ding, M. Dalstra, and C.C. Danielsen, J. Bone Jt. Surg. (Br) 79B, 995 (1997).

L. Frank, I. Hvid, and B. Pongsoipetch, J. Orthop. Res. 7, 432 (1989).

R. Antonius, H. Zilch, G. Bergmann, and R. Kolbel, Arch. Orthop. Unfall-Chir. 97, 95 (1980).

O. Lindahl, Acta Orthop. Scand. 47, 11 (1976).

T.J. Horn, O.L.A. Harrysson, D.J. Marcellin-Little, H.A. West, B.D.X. Lascelles, and R. Aman, Addit. Manuf. 1–4, 2 (2014).

R. Wauthle, J. van der Stok, S. Amin Yavari, J. Van Humbeeck, J.P. Kruth, A.A. Zadpoor, H. Weinans, M. Mulier, and J. Schrooten, Acta Biomater. 14, 217 (2015).

Acknowledgements

This project was supported by the National Key R&D Program of China through No. 2016 YFB 1101403, Key R&D Program of Guangdong Province, China (Grant No. 2018B090906003) and Key R&D Program of Shaanxi Province, China (Grant No. 2017ZDXM-GY-057). The authors thank Prof. Ma Qian of RMIT University for many insightful discussions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, H.P., Yang, K., Jia, L. et al. Tantalum Bone Implants Printed by Selective Electron Beam Manufacturing (SEBM) and Their Clinical Applications. JOM 72, 1016–1021 (2020). https://doi.org/10.1007/s11837-020-04016-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04016-8