Abstract

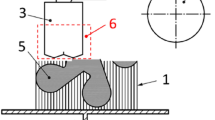

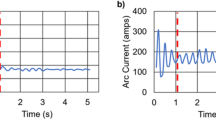

The feasibility of layer-by-layer manufacturing through high-aspect-ratio (HAR) nozzles for microextrusion of paste to deposit planes has been investigated. Various conditions for paste extrusion, including nozzle moving speed, piston speed, extrusion rate, and distance between the nozzle tip and substrate, have been evaluated. By linking various microextrusion parameters together with the aid of a critical distance concept derived from microextrusion using circular nozzles and addressing the extrusion delay in response to the change of the piston speed and air pocket problems properly, we successfully microextruded single planes, multilayer objects, and larger planes made of multiple smaller planes side by side through HAR nozzles. It is further demonstrated that the X–Y dimensions of an extruded plane in the steady-state extrusion stage are determined by the nozzle travel distance and the length of the HAR nozzle opening if microextrusion is conducted with proper conditions. However, the height of the extruded plane is not only determined by the microextrusion conditions, but also affected by the drying shrinkage of the paste after microextrusion. This demonstration of the feasibility of using a HAR nozzle machine opens the door to manufacture of multimaterial, multilayer devices with high productivity in the near future.

Similar content being viewed by others

References

J.J. Beaman, J.W. Barlow, D.L. Bourell, R.H. Crawford, H.L. Marcus, and K.P. McAlea, Solid Freeform Fabrication: A New Direction in Manufacturing (Norwell: Kluwer Academic, 1997).

L. Jepson, J.J. Beaman, D.L. Bourell, and K.L. Wood, in Proceedings of the 8th Annual SFF Symposium, eds. by D.L. Bourell, et al. (The University of Texas, Austin, 1997), pp. 67–79.

J. Mazumder, J. Choi, K. Nagarathnam, J. Koch, and D. Hetzner, JOM 49, 55 (1997).

J. Wang and L. Shaw, J. Am. Ceram. Soc. 89, 3285 (2006).

T.R. Jackson, H. Liu, N.M. Patrikalakis, E.M. Sachs, and M.J. Cima, Mater. Des. 20, 63 (1999).

J. Wang, L. Shaw, and T. Cameron, J. Am. Ceram. Soc. 89, 346 (2006).

S. Das, M. Wolhlert, J.J. Beaman, and D.L. Bourell, JOM 50, 17 (1998).

J.E. Crocker, S. Harrison, L.C. Sun, L. Shaw, and H. Marcus, JOM 50, 21 (1998).

M. Mott and J.R.G. Evans, Mater. Sci. Eng. 271, 344 (1999).

R. Chartoff, B. McMorrow, and P. Lucas, in Proceedings of the 14th Annual SFF Symposium, eds. by D.L. Bourell, et al. (The University of Texas, Austin, 2003), pp. 385–391.

L.C. Sun and L. Shaw, Metall. Mater. Trans. 30, 2549 (1999).

L.C. Sun, K.J. Jakubenas, J.E. Crocker, S. Harrison, L. Shaw, and H. Marcus, Mater. Manuf. Process. 13, 909 (1998).

D.M. Keicher and J.E. Smugeresky, JOM 49, 51 (1997).

B.Y. Ahn, E.B. Duoss, M.J. Motala, X. Guo, S. Park, Y. Xiong, R.G. Nuzzo, J.A. Rogers, and J.A. Lewis, Science 323, 1590 (2009).

R.A. Barry III, R.F. Shepherd, J.N. Hanson, R.G. Nuzzo, P. Wiltzius, and J.A. Lewis, Adv. Mater. 21, 2407 (2009).

X. Li, J. Wang, L. Shaw, and T. Cameron, Rapid Prototyp. J. 11, 52 (2005).

X. Li, J. Wang, and L. Shaw, Rapid Prototyp. J. 11, 140 (2005).

J.A. Lewis, J.E. Smay, J. Stuecker, and J. Cesarano III, J. Am. Ceram. Soc. 89, 3599 (2006).

J. Moon, J.E. Grau, V. Knezevic, M.J. Cima, and E.M. Sachs, J. Am. Ceram. Soc. 85, 755 (2002).

X. Zhao, J.R.G. Evans, and M.J. Edirisinghe, J. Am. Ceram. Soc. 85, 2113 (2002).

N. Reis, C. Ainsley, and B. Derby, J. Am. Ceram. Soc. 88, 802 (2005).

K.A.M. Seerden, N. Reis, J.R.G. Evans, P.S. Grant, J.W. Halloran, and B. Derby, J. Am. Ceram. Soc. 84, 2514 (2001).

J. Cesarano III, R. Segalman, and P. Calvert, Ceram. Ind. 148, 94 (1998).

B.A. Tuttle, J.E. Smay, J. Cesarano III, J.A. Voigt, T.W. Scofield, W.R. Olson, and J.A. Lewis, J. Am. Ceram. Soc. 84, 872 (2001).

M. Allahverdi, S.C. Danforth, M. Jafari, and A. Safari, J. Eur. Ceram. Soc. 21, 1485 (2001).

S. Rangarajan, G. Qi, N. Venkataraman, A. Safari, and S.C. Danforth, J. Am. Ceram. Soc. 83, 1663 (2000).

S.L. Morissette, J.A. Lewis, P.G. Clem, J. Cesarano III, and D.B. Dimos, J. Am. Ceram. Soc. 84, 2462 (2001).

R. Chang, J. Nam, and W. Sun, Tissue Eng. Part A 14, 41 (2008).

R. Landers and R. Mülhaupt, Macromol. Mater. Eng. 282, 17 (2000).

S.C. Singhal, Solid State Ionics 152–153, 405 (2002).

N.Q. Minh, Solid State Ionics 174, 271 (2004).

T. Tsai, E. Perry, and S. Barnett, J. Electrochem. Soc. 144, L130 (1997).

A.W. Tavernor, S.H.P. Li, A.J. Bell, and R. Stevens, J. Eur. Ceram. Soc. 19, 1691 (1999).

B.Y. Yu and W.C.J. Wei, J. Am. Ceram. Soc. 88, 2328 (2005).

F.J. Toal, J.P. Dougherty, and C.A. Randall, J. Am. Ceram. Soc. 81, 2371 (1998).

J. Wang and L. Shaw, Mater. Sci. Eng. 397, 314 (2005).

Q. Li and J.A. Lewis, Adv. Mater. 15, 1639 (2003).

E. Özkol, J. Ebert, K. Uibel, A.M. Wätjen, and R. Telle, J. Eur. Ceram. Soc. 29, 403 (2009).

R. Noguera, M. Lejeune, and T. Chartier, J. Eur. Ceram. Soc. 25, 2055 (2005).

J.H. Song, M.J. Edirisinghe, and J.R.G. Evans, J. Am. Ceram. Soc. 82, 3374 (1999).

B. Cappi, E. Özkol, J. Ebert, and R. Telle, J. Eur. Ceram. Soc. 28, 2625 (2008).

H. Wagata, T. Taniguchi, R. Gallage, A.K. Subramani, N. Sakamoto, T. Watanabe, M. Yoshimura, and N. Matsushita, J. Am. Ceram. Soc. 93, 381 (2010).

L. Li, S.M.I. Ayub, and L. Shaw, Ceram. Int. 42, 9086 (2016).

Acknowledgements

Financial support from the US National Science Foundation through Grant No. CMMI-1331735 is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shaw, L., Islam, M., Li, J. et al. High-Speed Additive Manufacturing Through High-Aspect-Ratio Nozzles. JOM 70, 284–291 (2018). https://doi.org/10.1007/s11837-017-2729-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2729-4