Abstract

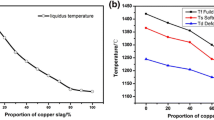

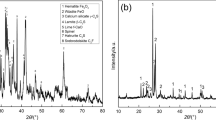

To lower the smelting temperature associated with the carbothermic reduction processing of laterite, the optimization of slag and alloy systems was investigated to enable the reduction of laterite ore in the molten state at 1723 K. The master Fe-Ni-Mo alloy was successfully produced at a lower temperature (1723 K). The liquidus of the slag decreased with the addition of oxide flux (Fe2O3 and CaO) and that of the ferronickel alloy decreased with the addition of Mo/MoO3. More effective metal–slag separation was achieved at 1723 K, which reduces the smelting temperature by 100 K compared with the current electric furnace process. A small addition of Mo/MoO3 not only decreased the melting point of ferronickel alloys but also served as a collector to aggregate the ferronickel sponges allowing them to grow larger. The FeO concentration in the slag and the nickel grade of the alloy decreased with increasing graphite reductant addition.

Similar content being viewed by others

References

G.M. Mudd, Ore Geol. Rev. 38, 9 (2010).

A.D. Dalvi, W.G. Bacon, and R. Osorn, Proceedings of the PDAC 2004 International Convention, Trade Show and Investors Exchange, (The Prospectors and Developers Association of Canada, Toronto, Canada, 2004), pp. 1–27.

M. Rao, G. Li, T. Jiang, J. Luo, Y. Zhang, and X. Fan, JOM 65, 1573 (2013).

T. Utigard and R.A. Bergman, Metall. Trans. B 23B, 271 (1993).

D. Huang, J. Zhang, R. Mao, and M. Cao, Rare Met. 30, 681 (2011).

B. Li, H. Wang, and Y. Wei, Miner. Eng. 24, 1556 (2011).

D. Zhu, Y. Cui, K. Vining, S. Hapugoda, J. Douglas, J. Pan, and G.L. Zheng, Int. J. Miner. Process. 106–109, 1 (2012).

C.T. Harris, J.G. Peacey, and C.A. Pickles, Miner. Eng. 54, 21 (2013).

T. Watanabe, S. Ono, H. Arai, and T. Matsumori, Int. J. Miner. Process. 19, 173 (1987).

H. Tsuji, ISIJ Int. 52, 1000 (2012).

H. Tsuji and N. Tachino, ISIJ Int. 52, 1724 (2012).

M. Liu, X. Lv, E. Guo, P. Chen, and Q. Yuan, ISIJ Int. 54, 1749 (2014).

S. Jin and T.H. Tiefel, “High remanence Fe-Mo-Ni alloys for magnetically actuated devices” (Google), https://www.google.ch/patents/US4340434, Accessed 30 March 2016.

“Stainless steel” (Wikipedia), https://en.wikipedia.org/wiki/Stainless_steel, Accessed 30 March 2016.

B. Zhao, R. Schonewille, E. Jak, and P.C. Hayes, The 48th Conference of Metallurgists, (Sudbury, Ontario, Canada, 2009), pp. 259–268.

“Iron-Nickel (Fe-Ni) Phase Diagram” (Computational Thermodynamics Inc.), http://www.calphad.com/iron-nickel.html, Accessed 30 March 2016.

E. Schuermann, M. Djurdjevic, and L. Nedeljkovic, Steel Res. 68, 383 (1997).

V. Raghavan, J. Phase Equilibria 24, 267 (2003).

Acknowledgement

The authors would like to thank Ms. Jie Yu for the lab assistance in the high-temperature experiments and financial support from Dongying Fangyuan Nonferrous Metals Co., Ltd and The University of Queensland. The authors also would like to thank Mr. Ron Rasch and Ms. Ying Yu from the Centre for Microscopy and Microanalysis (CMM) for technical support of EPMA and SEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, X., Cui, Z. & Zhao, B. Efficient Utilization of Nickel Laterite to Produce Master Alloy. JOM 68, 3006–3014 (2016). https://doi.org/10.1007/s11837-016-2028-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2028-5