Abstract

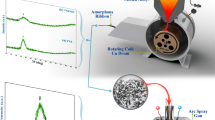

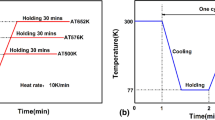

This work evaluated the mechanical strength and surface roughness of MgZn30Ca5 ribbon manufactured via a melt spinning technique for applications in the biomedical field. Annealing was performed at 280°C. The inner side (in contact with the wheel) and the outer side (not in contact with the wheel) of the ribbons were mechanically evaluated using nanoindentation, and its surfaces were analyzed by an optical profilometer. Differential scanning calorimeter (DSC) and X-ray diffraction (XRD) analyses were also performed to identify the structure and devitrification of the magnesium metallic glass (MgMG). The nanohardness and elastic modulus increased after annealing (p < 0.0001). No differences were seen in the strength between the two sides of the ribbons (p > 0.05). Although both sides of the ribbons showed different surface profiles (p < 0.0001), no statistical difference was detected in roughness parameters on either ribbon side before (p = 0.3094) and after (p = 0.8742) annealing. DSC curves showed disturbances in enthalpy attributed to a relaxation in the MgMG structure and free volume annihilation. The DRX diffractogram showed sharp peaks after annealing, with MgZn and Ca2Mg5Zn13 phases being identified. Although the use of MgMG in biomedical applications is promising, the ribbons displayed limited ductility, toughness, and a relevant embrittlement after the annealing procedure. There were significant changes in the surface profile of both sides of the ribbons. Nevertheless, neither annealing nor the ribbon side had influenced surface roughness parameters.

Similar content being viewed by others

References

Q.F. Li, H.R. Weng, Z.Y. Suo, Y.L. Ren, X.G. Yuan, and K.Q. Qiu, Mater. Sci. Eng. A 487, 301 (2008).

O. Hakimi and E. Aghion, Adv. Eng. Mater. 16, 364 (2014).

H.J. Yu, J.Q. Wang, X.T. Shi, D.V. Louzguine-Luzgin, H.K. Wu, and J.H. Perepezko, Adv. Funct. Mater. 23, 4793 (2013).

H.B. Yu, X. Shen, Z. Wang, L. Gu, W.H. Wang, and H.Y. Bai, Phys. Rev. Lett. 108, 1 (2012).

J.X. Zhao, R.T. Qu, F.F. Wu, Z.F. Zhang, B.L. Shen, M. Stoica, and J. Eckert, J. App. Phys. 105, 1 (2009).

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty, Acta Mater. 55, 4067 (2007).

C.A. Schuh, A.C. Lund, and T.G. Nieh, Acta Mater. 52, 5879 (2004).

C.A. Angell, K.L. Ngai, G.B. Mckenna, P.F. McMillan, and S.W. Martin, J. Appl. Phys. 88, 3113 (2000).

K.L. Ngai and M. Paluch, J. Chem. Phys. 120, 857 (2004).

F. Spaepen, Scr. Mater. 54, 363 (2006).

F. Spaepen, Acta Metall. 25, 407 (1977).

A.S. Argon, Acta Metall. 27, 47 (1979).

A.S. Argon and L.T. Shi, Acta Metall. 31, 499 (1983).

J.D. Cao, N.T. Kirkland, K.J. Laws, N. Birbilis, and M. Ferry, Acta Biomater. 8, 2375 (2012).

C. Fox, D. Ramsoomair, and C. Carte, South Med. J. 94, 1195 (2001).

M.B. Zemel, Am. J. Clin. Nutr. 79, 9075 (2004).

K.H. Brown, S.E. Wuehler, and J.M. Peerson, Food Nutr. Bull. 22, 113 (2001).

H. Wang and L. Boyapati, Implant Dent. 15, 8 (2006).

W.H. Wang, C. Dong, and C.H. Shek, Mater. Sci. Eng. R 44, 45 (2004).

V.A. Khonik and L.V. Spivak, Acta Mater. 44, 367 (1996).

J.J. Lewandowski, M. Shazly, and S. Nouri, Scr. Mater. 54, 337 (2006).

J.J. Lewandowski, W.H. Wangb, and A.L. Greerc, Philos. Mag. Lett. 85, 77 (2005).

W.L. Johnson and K. Samwer, Phys. Rev. Lett. 95, 195501 (2005).

D. Suh, R.H. Dauskardt, and J. Non-Cryst, Solids. 317, 181 (2003).

P. Murali and U. Ramamurty, Acta Mater. 53, 1467 (2005).

R.D. Conner, W.L. Johnson, N.E. Paton, and W.D. Nix, J. Appl. Phys. 94, 904 (2003).

J.J. Lewandowski and P. Lowhaphandu, Int. Mater. Rev. 43, 145 (1998).

H.A. Bruck, T. Christman, A.J. Rosakis, and W.L. Johnson, Scr. Metall. Mater. 30, 429 (1994).

R. Vaidyanathan, M. Dao, G. Ravichandran, and S. Suresh, Acta Mater. 49, 3781 (2001).

B.B. Medeiros, M.M. Medeiros, J. Fornell, J. Sort, M.D. Baró, and A.M. Jorge Jr, J. Non Cryst. Solids 425, 103 (2015).

F.S. Santos, J. Sort, J. Fornell, M.D. Baró, S. Surinãch, C. Bolfarini, W.J. Botta, and C.S. Kiminami, J. Non Cryst. Solids 356, 2251 (2010).

J. Eckert and A. Slipenyuk, Scr. Mater. 50, 39 (2004).

H.S. Chen, J. Appl. Phys. 49, 3289 (1978).

P. Czaja, W. Maziarz, J. Przewoznik, A. Zywczak, P. Ozga, M. Bramowicz, S. Kulesza, and J. Dutkiewicz, Intermetall 55, 1 (2014).

M. Dobromir, M. Negau, and H. Chiriac, J. Optoelectron. Adv. M. 8, 1752 (2006).

M. Gogebakan, O. Uzunb, T. Karaaslanc, and M. Keskinc, J. Mater. Process. Technol. 142, e87 (2003).

G. Lojen, I. Anzel, A. Kneissl, A. Krizman, E. Unterweger, B. Kosec, and M. Bizjak, J. Mater. Process. Technol. 162, 220 (2005).

T.B. Matias, G.H. Asato, B.T. Ramasco, W.J. Botta, C.S. Kiminami, and C. Bolfarini, J. Mater. Res. Technol. 3, 203 (2014).

Acknowledgements

We thank Professor Ronaldo de Biasi (Instituto Militar de Engenharia) for reading and considerably improving the article and the Carlos Chagas Foundation for Research Support from the Rio de Janeiro State (FAPERJ) and the National Council of Technological and Scientific Development from the Brazilian Government (CNPq) for supporting this study via Grants: E-26/201.759/2015, E-26/201.828/2015, E-26/010.001.262/2015, and 449472-2014-0.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernandes, D.J., Elias, C.N., de Souza Resende, C.R. et al. Mechanical Strength and Surface Roughness of Magnesium-Based Metallic Glasses. JOM 69, 1175–1184 (2017). https://doi.org/10.1007/s11837-016-1964-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-1964-4