Abstract

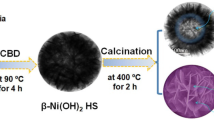

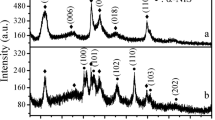

Hierarchical porous NiO/Al2O3 composites were successfully prepared by two-steps. First, the core-shell structured Al2O3 microspheres were prepared via a template-free hydrothermal route using KAl(SO4)2·12H2O and Al2(SO4)3·18H2O as aluminum source. Then, the NiO/Al2O3 composites with micro- and nano-hierarchical structures were prepared by a hydrothermal method combining the subsequent calcination process. The obtained characterization result presented that the morphology of hierarchical Al2O3 microsphere tuned to irregular platelets by simply varying Ni/Al ratios. The BET analysis showed that the special surface area from 52.12m2 g−1 to 214.8m2 g−1 after two hydrothermal complex process. Effects of Ni/Al ratio, adsorbent dosage, Congo red (CR) concentration, coexisting ions, adsorption time and temperature were investigated. The obtained results indicated that NiO/Al2O3 composite had the high adsorption efficiency (99.6%) and great adsorption capacity (186.9mg g−1) under the optimum conditions. The adsorption isotherm and kinetics data were found to be well fitted and in good agreement with the Langmuir isotherm model and pseudo-second order model, respectively. The hierarchical porous NiO/Al2O3 composites presented remarkably higher adsorption efficiency during five recycling, which showed their potential as the highly efficient adsorbent for removal of CR in wastewater.

Similar content being viewed by others

References

X. Peng, D. Huang, T. Odoom-Wubah, D. Fu, J. Huang and Q. Qin, J. Colloid Interface Sci., 430, 272 (2014).

S. Yang, L. Wang, X. Zhang, W. Yang and G. Song, Chem. Eng. J., 275, 315 (2015).

G. Crini, Bioresour. Technol., 97, 1061 (2006).

C. Lei, X. Zhu, B. Zhu, J. Yu and W. Ho, J. Colloid Interface Sci., 466, 238 (2016).

R. K. Gautam, V. Rawat, S. Banerjee, M. A. Sanroman, S. Soni, S. K. Singh and M. C. Chattopadhyaya, J. Mol. Liq., 212, 227 (2015).

B. Pal, R. Kaur and I. S. Grover, J. Ind. Eng. Chem., 33, 178 (2016).

L.-N. Jin, X.-Y. Qian, J.-G. Wang, H. Aslan and M. Dong, J. Colloid Interface Sci., 453, 270 (2015).

M. Liu, J. Xu, B. Cheng, W. Ho and J. Yu, Appl. Surf. Sci., 332, 121 (2015).

K. Zare, H. Sadegh, R. Shahryari-ghoshekandi, B. Maazinejad, V. Ali, I. Tyagi, S. Agarwal and V.K. Gupta, J. Mol. Liq., 212, 266 (2015).

V. Gupta, C. Millett, G. K. Walia, S. Kinra, A. Aggarwal, P. Prabhakaran, S. Bhogadi, A. Kumar, R. Gupta and D. Prabhakaran, J. Public Health, 23, 129 (2015).

V.K. Gupta, J. Environ. Manage., 90, 2313 (2009).

X. Huang, X. Bo, Y. Zhao, B. Gao, Y. Wang, S. Sun, Q. Yue and Q. Li, Bioresour. Technol., 165, 116 (2014).

J. Fang, X. Huang, X. Ouyang and X. Wang, Chem. Eng. J., 270, 309 (2015).

L. Zhang, X. Jiao, D. Chen and M. Jiao, Eur._J. Inorg. Chem., 2011, 5258 (2011).

C. Ottone, V. Farías Rivera, M. Fontana, K. Bejtka, B. Onida and V. Cauda, J. Mater. Sci. Technol., 30, 1167 (2014).

C. Peng, J. Zhang, Z. Xiong, B. Zhao and P. Liu, Micropor. Mesopor. Mater., 215, 133 (2015).

W. Cai, J. Yu, B. Cheng, B.-L. Su and M. Jaroniec, J. Phys. Chem. C., 113, 14739 (2009).

X. Li, J. Feng, J. Guo, A. Wang, R. Prins, X. Duan and Y. Chen, J. Catal., 334, 116 (2016).

T. Wang, L. Chang, B. Hatton, J. Kong, G. Chen, Y. Jia, D. Xiong and C. Wong, Mater. Sci. Eng. C., 43, 310 (2014).

T. Fan, X. Li, J. Ding, D. Zhang and Q. Guo, Micropor. Mesopor. Mater., 108, 204 (2008).

S. Cho, S. Kim, E. Oh, S.-H. Jung and K.-H. Lee, CrystEngComm, 11, 1650 (2009).

P. Lv, H. Zhao, Z. Zeng, C. Gao, X. Liu and T. Zhang, Appl. Surf. Sci., 329, 301 (2015).

R. Wang, Q. Li, D. Xie, H. Xiao and H. Lu, Appl. Surf. Sci., 279, 129 (2013).

X.-H. Zhang, X.-X. Li, H. Chen, T.-B. Li, W. Su and S.-D. Guo, Mater. Des., 92, 58 (2016).

S. B. Chandrasekhar, S. Sudhakara Sarma, M. Ramakrishna, P. Suresh Babu, T.N. Rao and B. P. Kashyap, Mater. Sci. Eng. A., 591, 46 (2014).

M.A. Behnajady and S. Bimeghdar, Chem. Eng. J., 239, 105 (2014).

F. Motahari, M.R. Mozdianfard and M. Salavati-Niasari, Process. Saf. Eviron., 93, 282 (2015).

X. Liu, Y. Yan, Z. Da, W. Shi, C. Ma, P. Lv, Y. Tang, G. Yao, Y. Wu and P. Huo, Chem. Eng. J., 241, 243 (2014).

K.S. Tong, M.J. Kassim and A. Azraa, Chem. Eng. J., 170, 145 (2011).

S. Chen, Q. Yue, B. Gao and X. Xu, J. Colloid Interface Sci., 349, 256 (2010).

T. Zhang, Q. Li, Y. Liu, Y. Duan and W. Zhang, Chem. Eng. J., 168, 665 (2011).

A.Y. Dursun and Ç.S. Kalayci, J. Hazard. Mater., 123, 151 (2005).

Z. P. Liang, Y.Q. Feng, S.X. Meng and Z.Y. Liang, Process Biochem., 40, 3218 (2005).

B.H. Hameed, D. K. Mahmoud and A.L. Ahmad, J. Hazard. Mater., 158, 65 (2008).

L. J. Kennedy, J. J. Vijaya, G. Sekaran and K. Kayalvizhi, J. Hazard. Mater., 149, 134 (2007).

Q.-S. Liu, T. Zheng, P. Wang, J.-P. Jiang and N. Li, Chem. Eng. J., 157, 348 (2010).

B. Cheng, Y. Le, W. Cai and J. Yu, J. Hazard. Mater., 185, 889 (2011).

W. Cai, J. Yu and M. Jaroniec, J. Mater. Chem., 20, 4587 (2010).

Z. Song, L. Chen, J. Hu and R. Richards, Nanatechnol., 20, 275707 (2009).

W. Cai, Y. Hu, J. Chen, G. Zhang and T. Xia, CrystEngComm, 14, 972 (2012).

R. Wang, Q. Li, N. Duan, T. Zhang and H. Lu, Res. Chem. Intermed., 41, 7899 (2015).

J. Fei, Y. Cui, X. Yan, W. Qi, Y. Yang, K. Wang, Q. He and J. Li, Adv. Mater., 20, 452 (2008).

R.-R. Shan, L.-G. Yan, Y.-M. Yang, K. Yang, S.-J. Yu, H.-Q. Yu, B.-C. Zhu and B. Du, J. Ind. Eng. Chem., 21, 561 (2015).

C. Lei, X. Zhu, B. Zhu, J. Yu and W. Ho, J. Colloid Interface Sci., 466, 238 (2016).

K. Singh and S. Mohan, Appl. Surf. Sci., 221, 308 (2004).

R. Leyva-Ramos, J. Rivera-Utrilla, N.A. Medellin-Castillo and M. Sanchez-Polo, Chem. Eng. J., 158, 458 (2010).

Y.-S. Ho, Water Res., 40, 119 (2006).

Y. S. Ho and G. McKay, Water Res., 34, 735 (2000).

H. Zaghouane-Boudiaf and M. Boutahala, Int. J. Miner. Process., 100, 72 (2011).

H. Zaghouane-Boudiaf, M. Boutahala, C. Tiar, L. Arab and F. Garin, Chem. Eng. J., 173, 36 (2011).

L. Wang and A. Wang, J. Hazard. Mater., 160, 173 (2008).

R. Ahmad and R. Kumar, Appl. Surf. Sci., 257, 1628 (2010).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

11814_2016_221_MOESM1_ESM.pdf

Structural evolution of hierarchical porous NiO/Al2O3 composites and their application for removal of dyes by adsorption

Rights and permissions

About this article

Cite this article

Rong, J., Zhang, T., Qiu, F. et al. Structural evolution of hierarchical porous NiO/Al2O3 composites and their application for removal of dyes by adsorption. Korean J. Chem. Eng. 34, 41–53 (2017). https://doi.org/10.1007/s11814-016-0221-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-016-0221-4