Abstract

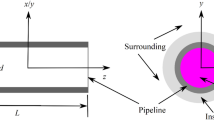

As for the factors affecting the heat transfer performance of complex and nonlinear oscillating heat pipe (OHP), grey relational analysis (GRA) was used to deal with the relationship between heat transfer rate of a looped copper-water OHP and charging ratio, inner diameter, inclination angel, heat input, number of turns, and the main influencing factors were defined. Then, forecasting model was obtained by using main influencing factors (such as charging ratio, interior diameter, and inclination angel) as the inputs of function chain neural network. The results show that the relative average error between the predicted and actual value is 4%, which illustrates that the function chain neural network can be applied to predict the performance of OHP accurately.

Similar content being viewed by others

References

GROLL M, KHANDEKAR S. Pulsating heat pipes: A challenge and still unsolved problem in heat pipe science [J]. Archives of Thermodynamics, 2002, 23(4): 17–28.

KHANDERKAR S, DOLLINGER N, GROLL M. Understanding operational regimes of pulsating heat pipes: An experimental study [J]. Applied Thermal Engineering, 2003, 23(6): 707–719.

RITTIDECH S, TERDTOON P, MURAKAMI M, KAMONPET P, JOMPAKDEE W. Correlation to predict heat transfer characteristics of a closed-end oscillating heat pipe at normal operating condition [J]. Applied Thermal Engineering, 2003, 23(4): 497–510.

TONG B Y, WONG T N, OOI K T. Closed-loop pulsating heat pipe [J]. Applied Thermal Engineering, 2001, 21(18): 1845–1862.

CUI Xiao-yu, WENG Jian-hua, GROLL M. Experimental investigation of heat transfer performance for the cooper/water pulsating heat pipe [J]. Journal of Engineering Thermo physics, 2003, 24(5): 864–86.

CHAROENSAWAN P, TERDTOON P. Thermal performance of horizontal closed-loop oscillating heat pipes [J]. Applied Thermal Engineering, 2003, 28(5): 460–466.

MA Yong-xi, ZHANG Hong. Analysis of heat transfer performance of oscillating heat pipes based on a central composite design [J]. Chinese Journal of Chinese Engineering, 2006, 14(2): 223–228.

CUI Xiao-yu, WENG Jian-hua, GROLL M. Heat transfer performance model of pulsating heat pipe based on neural network [J]. Journal of Chemical Industry and Engineering, 2003, 54(9): 1319–1322. (in Chinese)

CAYDAS U, HASCALIK A. Use of the grey relational analysis to determine optimum laser cutting parameters with multi-performance characteristics [J]. Optics & Laser Technology, 2008, 40(7): 987–994.

LIN J L, LIN C L. The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics [J]. International Journal of Machine Tools and Manufacture, 2002, 42(2): 237–244.

TSENG M L. Using linguistic preferences and grey relational analysis to optimize the thin-film sputtering process with multiple quality characteristic in color filter manufacturing [J]. Expert System with Applications, 2010, 37(1): 70–81.

RAO R, YADAVA V. Multi-objective optimization of Nd:YAG laser cutting of thin superalloy sheet using grey relational analysis with entropy measurement [J]. Optics & Laser Technology, 2009, 41(8): 922–930.

FU Chao-yang, ZHENG Jia-shen, ZHAO Jing-mao, XU Wei-dong. Application of grey relational analysis for corrosion failure of oil tubes [J]. Corrosion Science, 2001, 43(5): 881–889.

E Jia-qiang, ZHANG Hua-mei, GONG Jin-ke, WANG Yao-nan. Measurement system for gas flux in pipeline based on function chain neural network [J]. Journal of Central South University: Science and Technology, 2006, 39(5): 976–979. (in Chinese)

LIU Meng-xiang, ZHONG Zhi-hua, GONG Jin-ke. Data acquisition system of cylinder pressure in vehicle engine based on function chain neural network [J]. Journal of Hunan University: Natural Sciences, 2007, 34(4): 29–33. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(531107040300) supported by the Fundamental Research Funds for the Central Universities in China; Project(2006BAJ04B04) supported by the National Science and Technology Pillar Program during the Eleventh Five-year Plan Period of China

Rights and permissions

About this article

Cite this article

E, Jq., Li, Yq. & Gong, Jk. Function chain neural network prediction on heat transfer performance of oscillating heat pipe based on grey relational analysis. J. Cent. South Univ. Technol. 18, 1733–1737 (2011). https://doi.org/10.1007/s11771-011-0895-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-011-0895-z