Abstract

This contribution deals with the influence of anisotropic material degradation (damage) within numerical simulations of cold forging. For that purpose, two constitutive frameworks for modeling ductile damage are presented: an isotropic and an anisotropic model. In a first step, both models are calibrated based on a uniaxial tensile test. Then, the forward rod extrusion process is simulated with the isotropic model. The deformation of a characteristic element is transferred to the anisotropic model and the local response is investigated. Both models are compared to one another in terms of the process induced ductile damage. It will be shown, that the magnitude of the induced damage agrees reasonably well, but that the orientation of ductile damage is of major importance.

Similar content being viewed by others

References

Avitzur B (1968) Analysis of central bursting defects in extrusion and wire drawing. J Mech Phys Solids 90(1):79–91. https://doi.org/10.1115/1.3604608

Breuer D (2007) Bestimmung des Formänderungsvermögens bei der Kaltmassivumformung. Ph.D. thesis, RWTH Aachen, Werkzeugmaschinenlabor

Brünig M, Hagenbrock V, Gerke S (2018) Macroscopic damage laws based on analysis of microscopic unit cells. ZAMM J Appl Math Mech Zeitschrift für Angewandte Mathematik und Mechanik 98(2):181–194. https://doi.org/10.1002/zamm.201700188

Coleman BD, Noll W (1963) The thermodynamics of elastic materials with heat conduction and viscosity. Arch Rational Mech Anal 13(1):167–178. https://doi.org/10.1007/BF01262690

Ekh M, Menzel A, Runesson K, Steinmann P (2003) Anisotropic damage with the mcr effect coupled to plasticity. Int J Eng Sci 41(13):1535–1551. https://doi.org/10.1016/S0020-7225(03)00032-6

Green AE, Naghdi PM (1965) A general theory of an elastic–plastic continuum. Arch Rational Mech Anal 18(4):251–281. https://doi.org/10.1007/BF00251666

Halphen B, Nguyen Q (1975) Sur les matériaux standard généralisés. J Mécanique 14:39–63

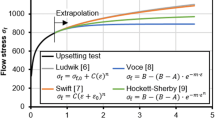

Hering O, Kolpak F, Tekkaya A (2019) Flow curves up to high strains considering load reversal and damage. Int J Mater Form 1:1. https://doi.org/10.1007/s12289-018-01466-z

Jennison HC (1930) Certain types of defects in copper wire caused by improper dies and drawing practice. Proc Inst Metals Div AIME 89:121–139

Lange K, Kammerer M, Phlandt K, Schöck J (2008) Fließpressen: Wirtschaftliche Fertigung metallischer Präzisionswerkstücke. Springer, Berlin

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. J Eng Mater Technol 107(1):83–89. https://doi.org/10.1115/1.3225775

Menzel A, Ekh M, Steinmann P, Runesson K (2002) Anisotropic damage coupled to plasticity: modelling based on the effective configuration concept. Int J Numer Methods Eng 54(10):1409–1430. https://doi.org/10.1002/nme.470

Ostwald R, Kuhl E, Menzel A (2019) On the implementation of finite deformation gradient-enhanced damage models. Comput Mech 64(3):847–877. https://doi.org/10.1007/s00466-019-01684-5

Reusch F (2003) Entwicklung und Anwendung eines nicht-lokalen Materialmodells zur Simulation duktiler Schädigung in metallischen Werkstoffen. Ph.D. thesis, TU Dortmund University, Institute of Mechanics

Seth BR (1964) Generalized strain measure with application to physical problems. In: Reiner M, Abir D (eds) Second-order effects in elasticity, plasticity and fluid dynamics. Pargamon Press, Oxford, pp 162–172

Soyarslan C, Tekkaya A, Akyz U (2008) Application of continuum damage mechanics in discontinuous crack formation: forward extrusion chevron predictions. ZAMM J Appl Math Mech Zeitschrift für Angewandte Mathematik und Mechanik 88(6):436–453. https://doi.org/10.1002/zamm.200800013

Tekkaya AE, Khalifa NB, Hering O, Meya R, Msylicki S, Walther F (2017) Forming-induced damage and its effects on product properties. CIRP Ann Manuf Technol 66(1):281–284. https://doi.org/10.1016/j.cirp.2017.04.113

Zapara M, Augenstein E, Helm D (2014) Prediction of damage in cold bulk forming processes. PAMM Proc Appl Math Mech 14(1):1037–1040. https://doi.org/10.1002/pamm.201410492

Zimerman Z, Avitzur B (1970) Analysis of the effect of strain hardening on central bursting defects in drawing and extrusion. J Eng Ind 92(1):135–145. https://doi.org/10.1115/1.3427698

Acknowledgements

Financial support from the German Research Foundation (DFG) via SFB/TR TRR 188 (278868966), projects A02, C01 and S01, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Langenfeld, K., Schowtjak, A., Schulte, R. et al. Influence of anisotropic damage evolution on cold forging. Prod. Eng. Res. Devel. 14, 115–121 (2020). https://doi.org/10.1007/s11740-019-00942-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-019-00942-y