Abstract

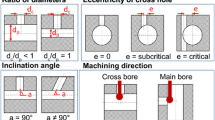

Regarding intersecting holes, the edges of cut are often difficult to access, as they are located inside the components. Hence it requires a lot of time and money to deburr them. In addition, burrs which come off in the later operation can lead to resultant damages. Examinations of intersecting holes showed that the effective exit surface angle, the angle between drill wall and exit surface, is crucial for burr formation. Based on the burr calculation for exit surfaces perpendicular to the drill axis, a method of calculation was developed out of the experimental results. By means of this calculation method the burr value g can be predicted for the short hole drilling of intersecting holes.

Similar content being viewed by others

References

Kuzmanovic RO (1998) Ein Drittel wird verschlafen. Produktion 12:28

Lung D (1997) Gratentstehung und Gratminimierung. Praxisforum Oberflächentechnik 15:5, 7–26

König W, Severt W (1995) Grate vermeiden bei der Bohr- und Fräsbearbeitung von Guss- und Stahlwerkstoffen. Ölhydraulik Pneumatik 39/5:405–409

Schäfer F (1992) Grundlagen zur Lösung von Entgratproblemen. In: Entgrat-Technik, Entwicklungsstand und Problemlösungen. Reihe Kontakt und Studium, Oberfläche, vol 392, pp 33–42, 236

Aurich, JC (2006) SpanSauber. Untersuchung zur Beherrschung der Sauberkeit von zerspanend hergestellten Bauteilen. Technische Universität Kaiserslautern

Dornfeld, D Min S, Reich-Weiser C (2004) Burr formation, deburring and surface finishing. In: 7th international conference on deburring and surface finishing, Berkeley

Schäfer F (1978) Gratbildung und Entgraten beim Umfangsstirnfräsen. VDI Ztg 120(1/2):47–55

Heisel U, Luik M, Eisseler R, Schaal M (2005) Prediction of parameters for the burr dimensions in short-hole drilling. CIRP Ann 54/1:79–82

Link R (1992) Gratbildung und Strategien zur Gratreduzierung. Dissertation RWTH Aachen

Heisel U, Eggert U, Luik M (1998) Kurzlochbohren ohne grate? Dima 53/3:54–58

Heisel U, Eggert U, Luik M (2000) Die Gratbildung minimieren. Aluminium Kurier News 3:14

Heisel U, Eggert U, Luik M (2000) Burr minimization in short hole drilling. Ann Ger Acad Soc Prod Eng VII/I:117–120

Heisel U, Schaal M (2006) Burr formation in short hole drilling with angled exit surfaces. Prod Eng XIII/2:177–180

Min S, Dornfeld D, Nakao Y (2003) Influence of exit surface angle on drilling burr formation. J Manuf Sci Eng 125:637–644

Acknowledgments

The examinations were carried out within the framework of a project funded by the German Research Foundation (DFG).