Abstract

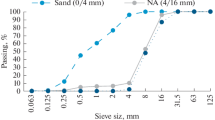

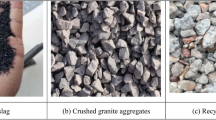

Aggregates are the biggest contributor to concrete volume and are a crucial parameter in dictating its mechanical properties. As such, a detailed experimental investigation was carried out to evaluate the effect of sand-to-aggregate volume ratio (s/a) on the mechanical properties of concrete utilizing both destructive and non-destructive testing (employing UPV (ultrasonic pulse velocity) measurements). For investigation, standard cylindrical concrete samples were made with different s/a (0.36, 0.40, 0.44, 0.48, 0.52, and 0.56), cement content (340 and 450 kg/m3), water-to-cement ratio (0.45 and 0.50), and maximum aggregate size (12 and 19 mm). The effect of these design parameters on the 7, 14, and 28 d compressive strength, tensile strength, elastic modulus, and UPV of concrete were assessed. The careful analysis demonstrates that aggregate proportions and size need to be optimized for formulating mix designs; optimum ratios of s/a were found to be 0.40 and 0.44 for the maximum aggregate size of 12 and 19 mm, respectively, irrespective of the W/C (water-to-cement) and cement content.

Similar content being viewed by others

References

Sagoe-Crentsil K K, Brown T, Taylor A H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cement and concrete research, 2001, 31(5): 707–712

Okonkwo V, Emmanuel E. A study of the effect of aggregate proportioning on concrete properties. American Journal of Engineering Research, 2018, 7: 61–67

Deepa C, Sathiya Kumari K, Sudha V P. Prediction of the compressive strength of high performance concrete mix using tree based modeling. International Journal of Computers and Applications, 2010, 6(5): 18–24

Concrete Committee of JSCE. No. 16: Standard Specifications for Concrete Structures-2007. Materials and Construction. Tokyo: Japan Society of Civil Engineers (JSCE), 2007

Bloem D L, Gaynor R D. Effects of aggregate properties on strength of concrete. Journal Proceedings, 1963, 60(10): 1429–1456

Uddin M T, Mahmood A H, Kamal M R I, Yashin S M, Zihan Z U A. Effects of maximum size of brick aggregate on properties of concrete. Construction & Building Materials, 2017, 134: 713–726

Yan S, Li J Z, Yang H Q, Lin Y Q. Effect of the maximum aggregate size on mechanical properties of four-grade RCC. In: 2011 International Conference on Electric Technology and Civil Engineering (ICETCE). Lushan: IEEE, 2011

Mardani-Aghabaglou A, Son A E, Felekoglu B, Ramyar K. Effect of cement fineness on properties of cementitious materials containing high range water reducing admixture. Journal of Green Building, 2017, 12(1): 142–167

Shen W, Yang Z G, Cao L H, Cao L, Liu Y, Yang H, Lu Z L, Bai J. Characterization of manufactured sand: Particle shape, surface texture and behavior in concrete. Construction & Building Materials, 2016, 114: 595–601

Jamkar S, Rao C J C, Research C. Index of aggregate particle shape and texture of coarse aggregate as a parameter for concrete mix proportioning. Cement and Concrete Research, 2004, 34(11): 2021–2027

Bashandy A A, Soliman N M. Influence of fine to coarse aggregate ratio and curing temperatures on the behavior of concrete. Engineering Research Journal, 2013, 138: 30–41

Lin W T. Effects of sand/aggregate ratio on strength, durability, and microstructure of self-compacting concrete. Construction & Building Materials, 2020, 242: 118046

Ruiz W M. Effect of Volume of Aggregate on the Elastic and Inelastic Properties of Concrete. Cornell University, 1966

Carrillo J, Ramirez J, Lizarazo-Marriaga J. Modulus of elasticity and Poisson’s ratio of fiber-reinforced concrete in Colombia from ultrasonic pulse velocities. Journal of Building Engineering, 2019, 23: 18–26

Mendes S E S, Oliveira R L N, Cremonez C, Pereira E, Pereira E, Medeiros-Junior R A. Electrical resistivity as a durability parameter for concrete design: Experimental data versus estimation by mathematical model. Construction & Building Materials, 2018, 192: 610–620

Medeiros-Junior R A, Gans P S, Pereira E, Pereira E. Electrical resistivity of concrete exposed to chlorides and sulfates. ACI Materials Journal, 2019, 116(3)

Mazer W, Lima M G, Medeiros-Junior R A. Fuzzy logic for estimating chloride diffusion in concrete. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 2018, 171(7): 542–551

de Bem D H, Lima D P B, Medeiros-Junior R A. Effect of chemical admixtures on concrete’s electrical resistivity. International Journal of Building Pathology and Adaptation, 2018, 36(2): 174–187

Anderson D A, Seals R K. Pulse velocity as a predictor of 28- and 90-day strength. Journal Proceedings. 1981, 78(2): 116–122

Kaplan M. The effects of age and water/cement ratio upon the relation between ultrasonic pulse velocity and compressive strength of concrete. Magazine of Concrete Research, 1959, 11(32): 85–92

Popovics S, Rose J L, Popovics J S. The behaviour of ultrasonic pulses in concrete. Cement and Concrete Research, 1990, 20(2): 259–270

Turgut P. Evaluation of the ultrasonic pulse velocity data coming on the field. In: 4th International Conference on NDE in Relation to Structural Integrity for Nuclear and Pressurized Components. London, 2004

Kheder G. A two stage procedure for assessment of in situ concrete strength using combined non-destructive testing. Materials and Structures, 1999, 32(6): 410–417

Elvery R H, Ibrahim L A M. Ultrasonic assessment of concrete strength at early ages. Magazine of Concrete Research, 1976, 28(97): 181–190

Jones R. The ultrasonic testing of concrete. Ultrasonics, 1963, 1(2): 78–82

Trtnik G, Kavčič F, Turk G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics, 2009, 49(1): 53–60

Mohammed T U, Mahmood A H. Effects of maximum aggregate size on UPV of brick aggregate concrete. Ultrasonics, 2016, 69: 129–136

Abo-Qudais S A. Effect of concrete mixing parameters on propagation of ultrasonic waves. Construction & Building Materials, 2005, 19(4): 257–263

Tanigawa Y, Baba K, Mori H. Estimation of concrete strength by combined nondestructive testing method. Special Publication, 1984, 82: 57–76

Yıldırım H, Sengul O. Modulus of elasticity of substandard and normal concretes. Construction & Building Materials, 2011, 25(4): 1645–1652

Ben-Zeitun A E. Use of pulse velocity to predict compressive strength of concrete. International Journal of Cement Composites and Lightweight Concrete, 1986, 8(1): 51–59

Del Rıo L M, Jimenez A, Lopez F, Rosa F J, Rufo M M, Paniagua J M. Characterization and hardening of concrete with ultrasonic testing. Ultrasonics, 2004, 42(1–9): 527–530

Ohdaira E, Masuzawa N. Water content and its effect on ultrasound propagation in concrete—The possibility of NDE. Ultrasonics, 2000, 38(1–8): 546–552

Mohammed T U, Rahman M N. Effect of types of aggregate and sand-to-aggregate volume ratio on UPV in concrete. Construction & Building Materials, 2016, 125: 832–841

ASTM. Standard Specification for Concrete Aggregates, ASTM C33 / C33M-16. West Conshohocken, PA: ASTM, 2016

BDS EN 197-1: 2000 Cement. Composition, specifications and conformity criteria for common cements. London: British Standards Institution, 2000

ASTM. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate, ASTM C127-15. West Conshohocken, PA: ASTM, 2015

ASTM. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate, ASTM C128-15. West Conshohocken, PA: ASTM, 2015

ASTM. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM C29/C29M-17a. West Conshohocken, PA: ASTM, 2017

ASTM. Standard Test Method for Resistance to Degradation of Small-size Coarse Aggregate by Abrasion Resistance and Impact in the Los Angeles Machine, ASTM C131. West Conshohocken, PA: ASTM, 2006

ASTM. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates, ASTM C136/C136M-19. West Conshohocken, PA: ASTM, 2019

ASTM. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory, ASTM C192. West Conshohocken, PA: ASTM, 2018

ASTM. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, ASTM C39/C39M-16. West Conshohocken, PA: ASTM, 2016

ASTM. Standard test method for splitting tensile strength of cylindrical concrete specimen, ASTM C496/C496M-11. West Conshohocken, PA: ASTM, 2011

ASTM. Standard Test Method for Pulse Velocity Through Concrete, ASTM C597-16. West Conshohocken, PA: ASTM, 2016

Panzera T H, Christoforo A L, Cota F P, Borges P R, Bowen C R. Ultrasonic pulse velocity evaluation of cementitious materials. Advances in Composite Materials — Analysis of Natural and Man-Made Materials, 2011, 17: 411–436

Shin H O, Yoo D Y, Lee J H, Lee S H, Yoon Y S. Optimized mix design for 180 MPa ultra-high-strength concrete. Journal of Materials Research and Technology, 2019, 8(5): 4182–4197

ACI 318-14 Building Code Requirements for Structural Concrete. Farmington Hills, MI: American Concrete Institute, 2014

Mendes S E S, Oliveira R L N, Cremonez C, Pereira E, Pereira E, Medeiros-Junior R A. Mixture Design of Concrete Using Ultrasonic Pulse Velocity. International Journal of Civil Engineering, 2020, 18(1): 113–122

Nash’t I H, A’bour S H, Sadoon A A. Finding an unified relationship between crushing strength of concrete and nondestructive tests. In: Middle East Nondestructive Testing Conference & Exhibition. Manama: Citeseer, 2005

Turgut P. Research into the correlation between concrete strength and UPV values. e-Journal of NDT, 2004, 12(12): 1–9

Hedjazi S, Castillo D. Relationships among compressive strength and UPV of concrete reinforced with different types of fibers. Heliyon, 2020, 6(3): e03646

Nash’t I H, A’bour S H, Sadoon A A. Finding an unified relationship between crushing strength of concrete and nondestructive tests. In: Middle East Nondestructive Testing Conference & Exhibition. 2005, 27–30

Solís-Carcaño R, Moreno E I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Construction & Building Materials, 2008, 22(6): 1225–1231

Lin Y, Shih-Fang K, Hsiao C, Chao-Peng L. Investigation of pulse velocity-strength relationship of hardened concrete. ACI Materials Journal, 2007, 104(4): 344

Bogas J A, Gomes M G, Gomes A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics, 2013, 53(5): 962–972

Ghosh R, Sagar S P, Kumar A, Gupta S K, Kumar S. Estimation of geopolymer concrete strength from ultrasonic pulse velocity (UPV) using high power pulser. Journal of building engineering, 2018, 16: 39–44

Mahure N, Vijh G K, Sharma P, Sivakumar N, Ratnam M. Correlation between pulse velocity and compressive strength of concrete. International Journal of Earth Sciences and Engineering, 2011, 4(6): 871–874

Panzera T H, Rubio J C, Bowen C R, Vasconcelos W L, Strecker K. Correlation between structure and pulse velocity of cementitious composites. Advances in cement research, 2008, 20(3): 101–108

Gameiro F, De Brito J, Correia da Silva D. Durability performance of structural concrete containing fine aggregates from waste generated by marble quarrying industry. Engineering Structures, 2014, 59: 654–662

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammed, T.U., Mahmood, A.H., Zunaied-Bin-Harun, M. et al. Destructive and non-destructive evaluation of concrete for optimum sand to aggregate volume ratio. Front. Struct. Civ. Eng. 15, 1400–1414 (2021). https://doi.org/10.1007/s11709-021-0779-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0779-8