Abstract

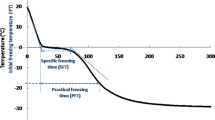

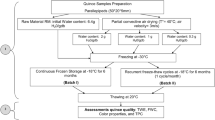

Partial air-drying, instant controlled pressure drop, freezing, and thawing operations were combined to minimize the texture loss of frozen/thawed apple fruits. Fresh apple samples (700% db) and samples previously dehydrated until different water contents [200, 100, and 30% dry basis (db)] and DIC treated at constant conditions (0.2 MPa, 25 s) were completely frozen at − 30 °C and at two different freezing velocities and then thawed at 4 °C. The effects of sample water content and freezing velocity on freezing/thawing durations and apple texture were assessed. Lower sample water content implied higher freezing and thawing rates, and lower freezing and thawing times. Indeed, freezing times are 108 min and 30 min for samples with water contents of 700% and 100% db, respectively. Thawing time was also reduced from 588 to 42 min for conventionally frozen and DIC-dehydrofrozen samples (100% db). During thawing, the amount of water exudate was approximately 12% (g/100 g residual water) for conventionally frozen apples at the lower freezing velocity. Whereas, it is lowered to 1.6% for 100% db DIC-dehydrofrozen samples. Moreover, the impact of freezing velocity on water exudate was significant and very important only for conventionally frozen apples (with high water content) and remains insignificant for DIC-dehydrofrozen samples with different water content levels. Thawed apple firmness was as higher as the water content was lower, without any significant impact of freezing velocity. Dehydrofreezing assisted by instant controlled pressure drop exhibited significant effects on reducing thawing duration and enhancing frozen apple fruit texture.

Similar content being viewed by others

References

B. Li, D.W. Sun, J. Food Eng. 54(3), 175 (2002)

E. Demir, K. Dymek, F.G. Galindo, Food Bioprocess Technol. 11, 809 (2018)

Z. Zhu, Z. Chen, Q. Zhou et al., Food Bioprocess Technol. 11, 1615 (2018)

M. Fuchigami, K. Miyazaki, N. Hyakumoto, J. Food Sci. 60(1), 132 (1995)

A.A. Khan, J.F. Vincent, J. Texture Stud. 27(2), 143 (1996)

B. Xu, M. Zhang, B. Bhandari et al., Food Bioprocess Technol. 8, 1366 (2015)

S. Chassagne-Berces, F. Fonseca, M. Citeau, M. Marin, LWT-Food Sci. Technol. 43(9), 1441 (2010)

C. James, G. Purnell, S. James, Food Bioprocess Technol. 7(5), 1219 (2014)

Y. Xin, M. Zhang, B. Adhikari, Food Bioprocess Technol. 7, 1736 (2014)

L. Ben Haj Said, S. Bellagha, K. Allaf, Food Bioprocess Technol. 8(5), 1102 (2015)

L. Cheng, D.W. Sun, Z. Zhu, Z. Zhang, Crit. Rev. Food Sci. Nutr. 57(4), 769 (2015)

W. Hajji, S. Bellagha, K. Allaf, J. Food Meas. Charact. 14, 353 (2020)

T. Norton, D. Sun, Food Bioprocess Technol. 1, 2 (2008)

S. Van Buggenhout, I. Messagie, V. Maes et al., Eur. Food Res. Technol. 223, 395 (2006)

AOAC. Association of Official Analytical Chemists (15th edn), by K. Helrich (ed) (Arlington, Virginia, 1990), p. 22201

T. Allaf, K. Allaf, Food Processing (Springer, New York, 2014)

L. Ben Haj Said, S. Bellagha, K. Allaf, Food Bioprocess Technol. 9(2), 252 (2016)

A. Maestrelli, R. Lo Scalzo, D. Lupi, G. Bertolo, D. Torreggiani, J. Food Eng. 49(2–3), 255 (2001)

W. Hajji, H. Gliguem, S. Bellagha, K. Allaf, Dry. Technol. 37, 1028 (2019)

L.A. Ramallo, R.H. Mascheroni, J. Food Eng. 99(3), 269 (2010)

C. Ilicali, F. Icier, J. Food Eng. 100(4), 696 (2010)

C.A. Miles, Z. Mayer, M.J. Morley, M. Houska, Int. J. Food Sci. Technol. 32, 389 (1997)

D. Góral, F. Kluza, W.E.L. Spiess, K. Kozłowicz, Food Technol. Biotechnol. 54(1), 3 (2016)

H.R. Bolin, C.C. Huxsoll, J. Food Sci. 58(2), 357 (1993)

A. Sormani, D. Maffi, G. Bertolo, D. Torreggiani, Food Sci. Technol. Int. 5(6), 479 (1999)

M.A. Haddad, S. Mounir, V. Sobolik, K. Allaf, Int. J. Food Eng. 4(6), 1064 (2008)

M. Kristiawan, V. Sobolik, L. Klima, K. Allaf, J. Food Eng. 102, 361 (2011)

J. Peng, J. Bi, J. Yi et al., Food Bioprocess Technol. 11, 1674 (2018)

M. Robbers, R.P. Singh, L.M. Cunha, J. Food Sci. 62(5), 1039 (1997)

Acknowledgements

This research was supported by a scholarship from the Ministry of Higher Education and Scientific Research of Tunisia. The authors acknowledge equally ABCAR-DIC PROCESS SAS, La Rochelle, France for providing an instant controlled pressure drop (DIC) unit.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ben Haj Said, L., Bellagha, S. & Allaf, K. Instant controlled pressure drop (DIC) assisted dehydrofreezing for improving freezing/thawing efficiency and apple fruit texture. Food Measure 15, 577–584 (2021). https://doi.org/10.1007/s11694-020-00668-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00668-x