Abstract

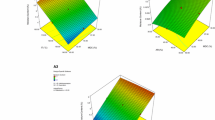

‘Cempedak’ (Artocarpus integer) is an aromatic fruit that looks similar to jackfruit. Response surface methodology was used to optimize the spray-drying process to produce ‘cempedak’ fruit powder, with inlet air temperature (140–180 °C) and maltodextrin (DE 10) concentrations (5–15% w/w) as independent variables. Statistical analysis revealed that these variables significantly affected process yield, moisture content, water activity, hygroscopicity, L* value of powder and carotenoid content. Inlet air temperature had a negative correlation with all significant variables. At the same time, maltodextrin concentration was found to be positively correlated with all significant powder variables except process yield and moisture content. The recommended optimum spray-drying conditions for drying ‘cempedak’ juice were inlet air temperature and maltodextrin concentration of 160 °C and 15% (w/w), respectively. Under optimized spray-drying conditions, the yield of ‘cempedak’ powder was 60.5%, with moisture content, water activity, hygroscopicity and carotenoid content of 6.07%, 0.22, 25.8 g/100 g and 1.00 mg/g, respectively.

Similar content being viewed by others

References

T.K. Lim, in Edible Medicinal and Non-Medicinal Plant, vol. 3. Fruits, pp. 337–343 (Springer, Dordrecht, 2012)

L.P. Pui, R. Karim, Y.A. Yusof, C.W. Wong, H.M. Ghazali, Physicochemical and sensory properties of selected ‘cempedak’ (Artocarpus integer L.) fruit varieties. Int. Food Res. J. 25(2), 861–869 (2018)

J. Janick, R.E. Paull, The Encyclopedia of Fruits and Nuts (Cambridge University Press, Cambridge, 2008)

S. Subhadrabandhu, Under-Utilized Tropical Fruits of Thailand, Rap publication 26 (Food and Agriculture Organization of the United Nations regional office for Asia and the Pacific, Bangkok, 2001)

C.H. Chong, C.L. Law, M. Cloke, C.L. Hii, L.C. Abdullah, W.R.W. Daud, Drying kinetics and product quality of dried Chempedak. J. Food Eng. 88(4), 522–527 (2008)

Department of Agriculture (DOA), Pakej teknologi cempedak (Jabatan Pertanian Malaysia, Putrajaya, 2001) (in Malay)

R.V. Tonon, C. Brabet, D. Pallet, P. Brat, M.D. Hubinger, Physicochemical and morphological characterisation of açai (Euterpe oleraceae Mart.) powder produced with different carrier agents. Int. J. Food Sci. Technol. 44, 1950–1958 (2009)

M. Cano-Chauca, P.C. Stringheta, A.M. Ramos, J. Cal-Vidal, Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov. Food Sci. Emerg. Technol. 6, 420–428 (2005)

S.Y. Quek, N.K. Chok, P. Swedlund, The physicochemical properties of spray dried watermelon powders. Chem. Eng. Process. 46, 386–392 (2007)

M. Khalilian Movahhed, M. Mohebbi, Spray drying and process optimization of carrot–celery juice. J. Food Process. Preserv. 40(2), 212–225 (2016)

I. Andrade, H. Flores, Optimization of spray drying of roselle extract (Hibiscus sabdariffa L.). In Proceedings of the 14th International Drying Symposium, vol. A, São Paulo, Brazil, pp. 597–604 (2004)

D.H. Huntington, The influence of the spray drying process on product properties. Dry. Technol. 22(6), 1261–1287 (2004)

G.R. Chegini, B. Ghabadian, Effect of spray-drying conditions on physical properties of orange juice powder. Dry. Technol. 23, 657–668 (2005)

S. Chew, C. Tan, L. Pui, P. Chong, B. Gunasekaran, K. Nyam, Encapsulation technologies: a tool for functional foods development. ITIJEE 8(5S), 154–160 (2019)

S.H. Yousefi, Z. Ehmam-Djomeh, S.M. Mousavi, Comparison of artificial neural network (ANN) and response surface methodology (RSM) in the prediction of quality parameters of spray-dried pomegranate juice. Dry. Technol. 27, 910–927 (2009)

G.E.G. Moreira, M.G.M. Costa, A.C.R. de Souza, E.S. de Brito, M.F.D. de Medeiros, H.M.C. de Azeredo, Physical properties of spray dried acerola extract as affected by temperature and drying aids. LWT Food Sci. Technol. 4, 641–645 (2009)

C.W. Wong, L.P. Pui, J.M.L. Ng, Production of spray-dried Sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. Int. Food Res. J. 22(4), 1631–1636 (2015)

F. Shavakhi, H.C. Boo, A. Osman, H.M. Ghazali, Effects of enzymatic liquefaction, maltodextrin concentration, and spray-dryer air inlet temperature on pumpkin powder characteristics. Food Bioprocess Technol. 5(7), 2837–2847 (2012)

L.S. Chang, S.M.E. Yong, L.P. Pui, Production of spray-dried “Terung Asam” (Solanum lasiocarpum Dunal) powder. Walailak J. Sci. Technol. (2020a) (in press)

L.S. Chang, Y.L. Tan, L.P. Pui, Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Braz. J. Food Technol. 23, e2019181 (2020b) (in press)

T. Mahendran, Physico-chemical properties and sensory characteristics of dehydrated guava concentrate: effect of drying method and maltodextrin concentration. Trop. Agric. Res. Ext. 13, 49–54 (2010)

B.R. Bhandari, N. Dutta, T. Howes, Problems associated with spray drying of sugar-rich food. Dry. Technol. 15, 671–684 (1997)

A.R. Nur‘Aliaa, M.K. Siti Mazlina, F.S. Taip, Effects of commercial pectinases application on selected properties of red pitaya juice. J. Food Process Eng. 34, 1523–1534 (2011)

J. Bakar, S.C. Ee, K. Muhammad, D.M. Hashim, N. Adzahan, Spray-drying optimization for red pitaya peel (Hylocereus polyrhizus). Food Bioprocess Technol. 6, 1332–1342 (2013)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp: effect of feed concentration. Dry. Technol. 22(10), 2309–2330 (2004)

R.V. Tonon, C. Brabet, M.D. Hubinger, Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 88, 411–418 (2008)

M.R. Zareifard, M. Niakousari, Z. Shokrollahi, S. Javadian, A feasibility study on the drying of lime juice: the relationship between the key operating parameters of a small laboratory spray dryer and product quality. Food Bioprocess Technol. 5, 1896–1906 (2012)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp-in dehumidified air: II. The effect on powder properties. J. Food Eng. 66, 35–42 (2005)

AOAC, Official Methods of Analysis (Association of Official Analytical Chemists Inc., Virginia, 2000)

D.B. Rodriguez-Amaya, M. Kimura, HarvestPlus Handbook for Carotenoid Analysis, vol. 2 (International Food Policy Research Institute, Washington, 2004)

Y.Z. Cai, H. Corke, Production and properties of spray-dried Amaranthus betacyanin prigments. J. Food Sci. 65, 1248–1252 (2000)

M.A. De Oliveira, G.A. de Maia, R.W. de Figueirado, A.C.R. de Souza, E.S. de Brito, H.M. de Azeredo, Addition of cashew tree gum to maltodextrin-based carriers for spray drying of cashew apple juice. Int. J. Food Sci. Technol. 44, 641–645 (2009)

C.A. Chopda, D.M. Barrett, Optimization of guava juice and powder production. J. Food Process. Preserv. 25, 411–430 (2001)

A.K. Shrestha, T. Ua-Arak, B.P. Adhikari, T. Howes, B.R. Bhandari, Glass transition behavior of spray dried orange juice powder measured by differential scanning calorimetry (DSC) and thermal mechanical compression test (TMCT). Int. J. Food Prop. 10(3), 661–673 (2007)

G.R. Chegini, B. Ghobadian, Spray dryer parameters for fruit juice drying. World J. Agric. Sci. 3(2), 230–236 (2007)

G. Caliskan, S.N. Dirim, The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food Bioprod. Process. 91, 539–548 (2013)

T.C. Kha, M.H. Nguyen, P.D. Roach, C.E. Stathopoulos, Microencapsulation of Gac oil: optimisation of spray drying conditions using response surface methodology. Powder Technol. 264, 298–309 (2014)

N.L. Tze, P.H. Chong, Y.A. Yusof, N.L. Chin, R.A. Talib, F.S. Tapi, M.G. Aziz, Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci. Biotechnol. 21(3), 675–682 (2012)

F.D.B. Abadio, A.M. Domingues, S.V. Borges, V.M. Oliveira, Physical properties of powdered pineapple (Ananas comosus) juice—effect of maltodextrin concentration and atomization speed. J. Food Eng. 64, 285–287 (2004)

J.A. Grabowski, V.D. Truong, C.R. Daubert, Spray-drying of amylase hydrolyzed sweet potato puree and physicochemical properties of powder. J. Food Sci. 71, 209–217 (2006)

T.C. Kha, M.H. Nguyen, P.D. Roach, Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 98, 385–392 (2010)

P. Mishra, S. Mishra, C.L. Mahanta, Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 92(3), 252–258 (2013)

M.F. Abu Bakar, F. Abdul Kari, E. Perisamy, Comparison of phytochemicals and antioxidant properties of different fruit parts of selected Artocarpus species from Sabah, Malaysia. Sains Malaysiana 44(3), 355–363 (2015)

J.A. Grabowski, V.D. Truong, C.R. Daubert, Nutritional and rheological characterization of spray dried sweet potato powder. LWT 41, 206–216 (2008)

E.R. Monsen, Dietary reference intakes for the antioxidant nutrients: vitamin C, vitamin E, selenium, and carotenoids. J. Am. Diet. Assoc. 100(6), 637–640 (2000)

S.S. Vidović, J.Z. Vladić, Z.G. Vaštag, Z.P. Zeković, L.M. Popović, Maltodextrin as a carrier of health benefit compounds in Satureja Montana dry powder obtained by spray drying technique. Powder Technol. 258, 209–215 (2014)

W. Wang, W.B. Zhou, Characterization of spray-dried soy sauce powders using maltodextrin as carrier. J. Food Eng. 109, 399–405 (2012)

G.R. Rodríguez-Hernández, R. González-García, A. Grajales-Lagunes, M.A. Ruiz-Cabrera, M. Abud-Archila, Spray-drying of cactus pear juice (Opuntia streptacantha): effect on the physicochemical properties of powder and reconstituted product. Dry. Technol. 23(4), 955–973 (2005)

Acknowledgements

This study was supported by the Universiti Putra Malaysia, Malaysia, under Project no. GP IPS/2013/9399839.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pui, L.P., Karim, R., Yusof, Y.A. et al. Optimization of spray-drying parameters for the production of ‘Cempedak’ (Artocarpus integer) fruit powder. Food Measure 14, 3238–3249 (2020). https://doi.org/10.1007/s11694-020-00565-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00565-3