Abstract

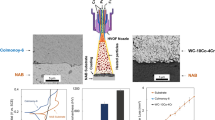

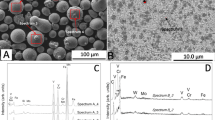

High-velocity oxygen fuel coatings were produced using gas-atomized Al62.5Cu25Fe12.5 and Al67Cu20Fe5Cr8 powders onto a ferritic stainless-steel substrate, resulting in two similar microstructures, consisting mainly of quasicrystalline phases. The goal of this work was to evaluate the performance of the quasicrystalline coatings under standard wear and corrosion tests. The samples were characterized by x-ray diffraction and scanning and transmission electron microscopy. Wear and friction behavior of the coatings and substrate were assessed by pin-on-disk tests. Vickers microhardness was also measured. The corrosion resistance was assessed through electrochemical measurements performed in alkaline and acidic medium in the absence and in the presence of chlorides. The coefficient of friction of the quasicrystalline coatings were inferior to the substrate, particularly the Al-Cu-Fe coating, with values close to 0.1. The Al62.5Cu25Fe12.5 alloy also showed the lowest specific wear rate, 1.7 × 10−4 mm3/N m, among the materials tested. In the presence of chlorides, the chromium containing coating presented better corrosion resistance with less surface damage after testing. However, the corrosion rate of the coating samples was low in both chloride-free alkaline and acidic conditions. Both Al62.5Cu25Fe12.5 and Al67Cu20Fe5Cr8 coatings presented corrosion potential considerably lower than the substrate for all tested media, which may be interesting for cathodic protection.

Similar content being viewed by others

References

J.-M. Dubois, Properties- and Applications of Quasicrystals and Complex Metallic Alloys, Chem. Soc. Rev., 2012, 41(20), p 6760

J.M. Dubois, Useful Quasicrystals, World Scientific Publishing Co. Pte. Ltd., Singapore, 2005

G. Laplanche, J. Bonneville, A. Joulain, V. Gauthier-Brunet, and S. Dubois, Mechanical Properties of Al-Cu-Fe Quasicrystalline and Crystalline Phases: An Analogy, Intermetallics, 2014, 50, p 54-58. https://doi.org/10.1016/j.intermet.2014.02.004

E. Huttunen-Saarivirta, Microstructure, Fabrication and Properties of Quasicrystalline Al-Cu-Fe Alloys: A Review, J. Alloys Compd., 2004, 363(1-2), p 154-178. https://doi.org/10.1016/S0925-8388(03)00445-6

C. Dong and J.M. Dubois, Quasicrystals and Crystalline Phases in Al65Cu20Fe10Cr5 Alloy, J. Mater. Sci., 1991, 26(6), p 1647-1654. https://doi.org/10.1007/BF00544677

J.F. Liu, Z.Q. Yang, and H.Q. Ye, Direct Observation of Solid-State Reversed Transformation from Crystals to Quasicrystals in a Mg Alloy, Sci. Rep., 2015, 5, p 1-10

K.F. Kelton, W.J. Kim, and R.M. Stroud, A Stable Ti-Based Quasicrystal, Appl. Phys. Lett., 1997, 70(24), p 3230-3232. https://doi.org/10.1063/1.119133

K.F. Kelton and P.C. Gibbons, Hydrogen Storage in Quasicrystals, MRS Bull., 1997, 22(11), p 69-72

J.L. Libbert, J.Y. Kim, and K.F. Kelton, Oxygen in Ti-(Cr, Mn)-Si Icosahedral Phases and Approximants, Philos. Mag. A, 1999, 79(9), p 2209-2225. https://doi.org/10.1080/01418619908210418

J.L. Libbert, K.F. Kelton, P.C. Gibbons, and A.I. Goldman, Large Unit Cell Crystal Approximant in Ti-Cr-Si Alloys, J. Non-Cryst. Solids, 1993, 153-154, p 53-57. https://doi.org/10.1016/0022-3093(93)90313-M

W. Wolf, R. Schulz, S. Savoie, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Structural, Mechanical and Thermal Characterization of an Al-Co-Fe-Cr Alloy for Wear and Thermal Barrier Coating Applications, Surf. Coat. Technol., 2017, 319, p 241-248. https://doi.org/10.1016/j.surfcoat.2017.03.066

J.M. Dubois, S.S. Kang, and J. Von Stebut, Quasicrystalline Low-Friction Coatings, J. Mater. Sci. Lett., 1991, 10(9), p 537-541. https://doi.org/10.1007/BF00726930

W. Wolf, L.P.M. e Silva, G. Zepon, C.S. Kiminami, C. Bolfarini, and W.J. Botta, Single Step Fabrication by Spray Forming of Large Volume Al-Based Composites Reinforced with Quasicrystals, Scr. Mater., 2020, 181, p 86-91. https://doi.org/10.1016/j.scriptamat.2020.02.018

K. Lee, J. Hsu, D. Naugle, and H. Liang, Multi-Phase Quasicrystalline Alloys for Superior Wear Resistance, Mater. Des., 2016, 108, p 440-447. https://doi.org/10.1016/j.matdes.2016.06.113

C. Zhou, F. Cai, J. Kong, S. Gong, and H. Xu, A Study on the Tribological Properties of Low-Pressure Plasma-Sprayed Al-Cu-Fe-Cr Quasicrystalline Coating on Titanium Alloy, Surf. Coat. Technol., 2004, 187(2-3), p 225-229. https://doi.org/10.1016/j.surfcoat.2004.03.013

L.P. Feng, T.M. Shao, Y.J. Jin, E. Fleury, D.H. Kim, and D.R. Chen, Temperature Dependence of the Tribological Properties of Laser Re-Melted Al-Cu-Fe Quasicrystalline Plasma Sprayed Coatings, J. Non-Cryst. Solids, 2005, 351(3), p 280-287. https://doi.org/10.1016/j.jnoncrysol.2004.08.269

P. Archambault, P. Plaindoux, E. Belin-Ferre, and J.M. Dubois, Thermal and Electronic Properties of an AlCoFeCr Approximant of the Decagonal Phase, Mat. Res. Soc. Symp., 1999, 553, p 409-414

E. Leshchinsky, A. Sobiesiak, and R. Maev, Intermetallic Al-, Fe-, Co- and Ni-Based Thermal Barrier Coatings Prepared by Cold Spray for Applications on Low Heat Rejection Diesel Engines, J. Therm. Spray Technol., 2018, 27(3), p 456-470. https://doi.org/10.1007/s11666-017-0681-z

E. Fleury, W.T. Kim, J.S. Kim, D.H. Kim, W.T. Kim, H.S. Ahn, and S.M. Lee, C Omparative Study of the Tribological Behavior of Thermal Sprayed Quasicrystalline Coating Layers, J. Alloys Compd., 2002, 342, p 321-325

D. Lu, J.P. Celis, S. Kenzari, V. Fournée, and D.B. Zhou, Tribological Behavior of Aluminum Matrix Composites Containing Complex Metallic Alloys AlCuFeB or AlCuFeCr Particles, Wear, 2011, 270(7-8), p 528-534. https://doi.org/10.1016/j.wear.2011.01.007

D.S. Shaitura and A.A. Enaleeva, Fabrication of Quasicrystalline Coatings: A Review, Crystallogr. Reports, 2007, 52(6), p 945-952. https://doi.org/10.1134/S1063774507060041

S. Siegmann, P. Kern, L. Rohr, and P.P. Bandyopadhyay, Tribological and Corrosion Behavior of Vacuum Plasma Sprayed Ti-Zr-Ni Quasicrystalline Coatings, J. Therm. Spray Technol., 2007, 16(5-6), p 947-953

D.J. Sordelet, S.D. Widener, Y. Tang, and M.F. Besser, Characterization of a Commercially Produced Al-Cu-Fe-Cr Quasicrystalline Coating, Mater. Sci. Eng. A, 2000, 294-296, p 834-837

W. Wolf, L.C.R. Aliaga, D.N. Travessa, C.R.M. Afonso, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Enhancement of Mechanical Properties of Aluminum and 2124 Aluminum Alloy by the Addition of Quasicrystalline Phases, Mater. Res., 2016, 19(suppl 1), p 74-79. https://doi.org/10.1590/1980-5373-mr-2016-0088

K. Stan-Głowińska, L. Lityńska-Dobrzyńska, B. Kania, J. Dutkiewicz, Ł. Rogal, W. Skuza, J. Wojewoda-Budka, M.A. Gordillo, and J.M. Wiezorek, Effects of Hot-Compaction on the Structure and Properties of Al-Mn-Fe-X Alloys Strengthened with Quasi-Crystalline Icosahedral Phase, Mater. Des., 2017, 126, p 162-173. https://doi.org/10.1016/j.matdes.2017.04.043

M. Galano, F. Audebert, I.C. Stone, and B. Cantor, Nanoquasicrystalline Al-Fe-Cr-Based Alloys. Part I: Phase Transformations, Acta Mater., 2009, 57(17), p 5107-5119. https://doi.org/10.1016/j.actamat.2009.07.011

M. Galano, F. Audebert, G. Escorial, I.C. Stone, and B. Cantor, Nanoquasicrystalline Al-Fe-Cr-Based Alloys. Part II. Mechanical Properties, Acta Mater., 2009, 57(17), p 5120-5130. https://doi.org/10.1016/j.actamat.2009.07.009

G.Y. Koga, A.M.B. e Silva, W. Wolf, C.S. Kiminami, C. Bolfarini, and W.J. Botta, Microstructure and Mechanical Behavior of Al92Fe3Cr2X3 (X = Ce, Mn, Ti, and V) Alloys Processed by Centrifugal Force Casting, J. Mater. Res. Technol., 2019, 8(2), p 2092-2097. https://doi.org/10.1016/j.jmrt.2018.12.022

B.A. Silva Guedes de Lima, R. Medeiros Gomes, S.J. Guedes de Lima, D. Dragoe, M.G. Barthes-Labrousse, R. Kouitat-Njiwa, and J.M. Dubois, Self-Lubricating, Low-Friction, Wear-Resistant Al-Based Quasicrystalline Coatings, Sci. Technol. Adv. Mater., 2016, 17(1), p 71-79. https://doi.org/10.1080/14686996.2016.1152563

E. Deltombe and M. Pourbaix, The Electrochemical Behavior of Aluminum—Potential PH Diagram of the System AI-H2O at 25°C, Corrosion, 1958, 14(11), p 16-20. https://doi.org/10.5006/0010-9312-14.11.16

R.T. Li, V.K. Murugan, Z.L. Dong, and K.A. Khor, Comparative Study on the Corrosion Resistance of Al-Cr-Fe Alloy Containing Quasicrystals and Pure Al, J. Mater. Sci. Technol., 2016, 32(10), p 1054-1058. https://doi.org/10.1016/j.jmst.2016.07.005

W. Wolf, S.A. Kube, S. Sohn, Y. Xie, J.J. Cha, B.E. Scanley, C.S. Kiminami, C. Bolfarini, W.J. Botta, and J. Schroers, Formation and Stability of Complex Metallic Phases Including Quasicrystals Explored through Combinatorial Methods, Sci. Rep., 2019, 9(1), p 7136. https://doi.org/10.1038/s41598-019-43666-w

S.M. Lee, H.J. Jeon, B.H. Kim, W.T. Kim, and D.H. Kim, Solidification Sequence of the Icosahedral Quasicrystal Forming Al-Cu-Fe Alloys, Mater. Sci. Eng. A, 2001, 304-306(1-2), p 871-878

D. Holland-Moritz, J. Schroers, B. Grushko, D.M. Herlach, and K. Urban, Dependence of Phase Selection and Micro Structure of Quasicrystal-Forming Al-Cu-Fe Alloys on the Processing and Solidification Conditions, Mater. Sci. Eng. A, 1997, 226-228, p 976-980. https://doi.org/10.1016/S0921-5093(96)10830-3

W. Wolf, F.G. Coury, M.J. Kaufman, C. Bolfarini, C.S. Kiminami, and W.J. Botta, The Formation of Quasicrystals in Al-Cu-Fe-(M = Cr, Ni) Melt-Spun Ribbons, J. Alloys Compd., 2018, 731, p 1288-1294. https://doi.org/10.1016/j.jallcom.2017.09.139

F.R.P. Feitosa, R.M. Gomes, M.M.R. Silva, S.J.G. De Lima, and J.M. Dubois, Effect of Oxygen/Fuel Ratio on the Microstructure and Properties of HVOF-Sprayed Al59Cu25.5Fe12.5B3 Quasicrystalline Coatings, Surf. Coat., 2018, 353, p 171-178. https://doi.org/10.1016/j.surfcoat.2018.08.081

E. Fleury, S.M. Lee, W.T. Kim, and D.H. Kim, Efects of Air Plasma Spraying Parameters on the Al-Cu-Fe Quasicrystalline Coating Layer, J. Non-Cryst. Solids, 2000, 278, p 194-204

D.J. Sordelet, M.F. Besser, and J.L. Logsdon, Abrasive Wear Behavior of Al-Cu-Fe Quasicrystalline Composite Coatings, Mater. Sci. Eng. A, 1998, 255, p 54-65

Y. Kang, C. Zhou, S. Gong, and H. Xu, Electrochemical Behavior of Low-Pressure Plasma-Sprayed Al-Cu-Fe-Cr Quasicrystalline Coating, Vacuum, 2005, 79(3-4), p 148-154

W. Wolf, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Designing New Quasicrystalline Compositions in Al-Based Alloys, J. Alloys Compd., 2020, 823, p 153765. https://doi.org/10.1016/j.jallcom.2020.153765

E. Ura-Binczyk, N. Homazava, A. Ulrich, R. Hauert, M. Lewandowska, K.J. Kurzydlowski, and P. Schmutz, Passivation of Al-Cr-Fe and Al-Cu-Fe-Cr Complex Metallic Alloys in 1 M H2SO4 and 1 M NaOH Solutions, Corros. Sci., 2011, 53(5), p 1825-1837. https://doi.org/10.1016/j.corsci.2011.01.061

E. Ura-Binczyk, A. Beni, M. Lewandowska, and P. Schmutz, Passive Oxide Film Characterisation on Al-Cr-Fe and Al-Cu-Fe-Cr Complex Metallic Alloys in Neutral to Alkaline Electrolytes by Photo- and Electrochemical Methods, Electrochim. Acta, 2014, 139, p 289-301. https://doi.org/10.1016/j.electacta.2014.07.010

B. Zaid, D. Saidi, A. Benzaid, and S. Hadji, Effects of PH and Chloride Concentration on Pitting Corrosion of AA6061 Aluminum Alloy, Corros. Sci., 2008, 50(7), p 1841-1847

S. Il Pyun and S.M. Moon, Corrosion Mechanism of Pure Aluminium in Aqueous Alkaline Solution, J. Solid State Electrochem., 2000, 4(5), p 267-272

A. Korchef and A. Kahoul, Corrosion Behavior of Commercial Aluminum Alloy Processed by Equal Channel Angular Pressing, Int. J. Corros., 2013, https://doi.org/10.1155/2013/983261

J. Skrovan, A. Alfantazi, and T. Troczynski, Enhancing Aluminum Corrosion in Water, J. Appl. Electrochem., 2009, 39(10), p 1695-1702

Z. Szklarska-Smialowska, Pitting Corrosion of Aluminum, Corros. Sci., 1999, 41(9), p 1743-1767

I. Hutchings and P. Shipway, Friction, Tribology, 2nd ed., I. Hutchings and P. Shipway, Ed., Elsevier, Amsterdam, 2017, p 37-77 https://doi.org/10.1016/B978-0-08-100910-9.00003-9

D.A. Rabson, Toward Theories of Friction and Adhesion on Quasicrystals, Prog. Surf. Sci., 2012, 87(9-12), p 253-271. https://doi.org/10.1016/j.progsurf.2012.10.001

J. Dubois, New Prospects from Potential Applications of Quasicrystalline Materials, Mater. Sci. Eng. A, 2000, 294-296, p 4-9

ASTM International, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus G99-17, Annual Book ASTM Standards, 2017, 05(2016), p 1-6

R.P. Matthews, C.I. Lang, and D. Shechtman, Sliding Wear of Quasicrystalline Coatings, Tribol. Lett., 1999, 2000(7), p 179-181

W. Wolf, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Fabrication of Al-Matrix Composite Reinforced with Quasicrystals Using Conventional Metallurgical Fabrication Methods, Scr. Mater., 2019, 173, p 21-25. https://doi.org/10.1016/j.scriptamat.2019.07.044

U. Köster, W. Liu, H. Liebertz, and M. Michel, Mechanical Properties of Quasicrystalline and Crystalline Phases in Al-Cu-Fe Alloys, J. Non-Cryst. Solids, 1993, 153-154, p 446-452. https://doi.org/10.1016/0022-3093(93)90393-C

I. Hutchings and P. Shipway, Sliding Wear, Tribology, 2nd ed., I. Hutchings and P. Shipway, Ed., Elsevier, Amsterdam, 2017, p 107-164 https://doi.org/10.1016/b978-0-08-100910-9.00005-2

S. Pedrazzini, M. Galano, F. Audebert, D.M. Collins, F. Hofmann, B. Abbey, A.M. Korsunsky, M. Lieblich, A. GarciaEscorial, and G.D.W. Smith, Strengthening Mechanisms in an Al-Fe-Cr-Ti Nano-Quasicrystalline Alloy and Composites, Mater. Sci. Eng. A, 2016, 672, p 175-183. https://doi.org/10.1016/j.msea.2016.07.007

H.R. Leonard, S. Rommel, T.J. Watson, T. Policandriotes, and M. Aindow, Development of Quasicrystal Morphology in Gas-Atomized Icosahedral-Phase-Strengthened Aluminum Alloy Powders, Mater. Des., 2019, 182, p 108094. https://doi.org/10.1016/j.matdes.2019.108094

F. Ali, S. Scudino, M.S. Anwar, R.N. Shahid, V.C. Srivastava, V. Uhlenwinkel, M. Stoica, G. Vaughan, and J. Eckert, Al-Based Metal Matrix Composites Reinforced with Al-Cu-Fe Quasicrystalline Particles: Strengthening by Interfacial Reaction, J. Alloys Compd., 2014, 607, p 274-279. https://doi.org/10.1016/j.jallcom.2014.04.086

K. Stan-Głowińska, L. Lityńska-Dobrzyńska, J. Morgiel, A. Góral, M.A. Gordillo, and J.M. Wiezorek, Enhanced Thermal Stability of a Quasicrystalline Phase in Rapidly Solidified Al-Mn-Fe-X Alloys, J. Alloys Compd., 2017, 702, p 216-228. https://doi.org/10.1016/j.jallcom.2016.12.383

Acknowledgments

The authors are grateful for the financial support granted by FAPESP (Processes No. 2015/09008-0 and No. 2013/05987-8), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001 and CNPq. The authors are also grateful for the technical assistance on TEM, SEM analysis and sample preparation from Laboratory of Structure Characterization of Federal University of São Carlos (UFSCar).

Author information

Authors and Affiliations

Contributions

WW, GYK, CB, CSK, and WJB designed the study. WW, RS, and SS fabricated the samples. WW and GYK characterized the samples. All authors contributed on data analysis, discussing and/or manuscript writing.

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wolf, W., Koga, G.Y., Schulz, R. et al. Wear and Corrosion Performance of Al-Cu-Fe-(Cr) Quasicrystalline Coatings Produced by HVOF. J Therm Spray Tech 29, 1195–1207 (2020). https://doi.org/10.1007/s11666-020-01053-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01053-2