Abstract

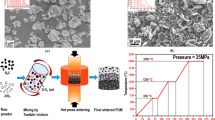

Nanostructured thermal barrier coatings (nano-TBCs) are being extensively studied because of their excellent thermal barrier properties. The occurrence of sintering in TBCs is inevitable in service; however, accelerated sintering of the nano-TBCs may cause premature failure. This study focuses on the changes of microstructure and thermal conductivity of bimodal nano-TBCs during thermal exposure. Results show that there are two stages in the sintering process. It was found that the thermal conductivity increased rapidly in the first stage (from 0 to 20 h), with the rate of increase in normalized thermal conductivity equal to 140% of bimodal coating. The continuous healing of the pores was the main structural change. During the following stage (20 to 100 h), the thermal conductivity decreased with the rate of increase in normalized thermal conductivity equal to − 8% of bimodal coating. The change of structure was the opening of pores. Furthermore, self-enhancing behavior of bimodal composite coatings was discovered. The phenomenon of inevitable sintering in thermodynamics can be used to introduce large-aspect-ratio pores in the in-depth direction, which can greatly slow down the increase in thermal conductivity in service and ultimately increase the lifetime of the thermal insulation. Based on a full study of the sintering mechanism of composite coatings, the present study sheds light on the structural adjustments that lead to a lower thermal conductivity and longer service life in the advanced TBC during high-temperature service.

Similar content being viewed by others

References

J. Ekberg, A. Ganvir, U. Klement, S. Creci, and L. Nordstierna, The Influence of Heat Treatments on the Porosity of Suspension Plasma-Sprayed Yttria-Stabilized Zirconia Coatings, J. Therm. Spray Technol., 2018, 27(3), p 391-401

X. Ma and P. Ruggiero, Practical Aspects of Suspension Plasma Spray for Thermal Barrier Coatings on Potential Gas Turbine Components, J. Therm. Spray Technol., 2018, 27(4), p 591-602

B. Zhang, L. Cheng, Y. Lu, and Q. Zhang, Scalable Preparation of Graphene Reinforced Zirconium Diboride Composites with Strong Dynamic Response, Carbon, 2018, https://doi.org/10.1016/j.carbon.2018.07.067

H. Wang, G. Muralidharan, D.N. Leonard, J.A. Haynes, W.D. Porter, R.D. England, and S. Sampath, Microstructural Analysis and Transport Properties of Thermally Sprayed Multiple-Layer Ceramic Coatings, J. Therm. Spray Technol., 2018, 27(3), p 371-378

R.A. Miller, Thermal Barrier Coatings for Aircraft Engines: History and Directions, J. Therm. Spray Technol., 1997, 6(1), p 35-42

S. Deng, P. Wang, Y. He, and J. Zhang, Surface Microstructure and High Temperature Oxidation Resistance of Thermal Sprayed NiCoCrAlY Bond-Coat Modified by Cathode Plasma Electrolysis, J. Mater. Sci. Technol., 2017, 33(9), p 1055-1060

W.Y. Li, K. Yang, S. Yin, X.W. Yang, Y.X. Xu, and R. Lupoi, Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review, J. Mater. Sci. Technol., 2017, https://doi.org/10.1016/j.jmst.2017.09.015

C. Huang, W. Li, Y. Xie, M.P. Planche, H. Liao, and G. Montavon, Effect of Substrate Type on Deposition Behavior and Wear Performance of Ni-Coated Graphite/Al Composite Coatings Deposited by Cold Spraying, J. Mater. Sci. Technol., 2017, 33(4), p 338-346

X.G. Chen, H. Zhang, H.S. Zhang, and G. Li, Ce1−xSmxO2−x/2—A Novel Type of Ceramic Material for Thermal Barrier Coatings, J. Adv. Ceram., 2016, 5(3), p 244-252

W.W. Zhang, G.R. Li, Q. Zhang, and G.J. Yang, Comprehensive Damage Evaluation of Localized Spallation of Thermal Barrier Coatings, J. Adv. Ceram., 2017, 6(3), p 230-239

R. Darolia, Thermal Barrier Coatings Technology: Critical Review, Progress Update, Remaining Challenges and Prospects, Int. Mater. Rev., 2013, 58(6), p 315-348

L. Wang, Y. Wang, X.G. Sun, J.Q. He, Z.Y. Pan, Y. Zhou, and P.L. Wu, Influence of Pores on the Thermal Insulation Behavior of Thermal Barrier Coatings Prepared by Atmospheric Plasma Spray, Mater. Des., 2011, 32(1), p 36-47

R. Ghasemi and H. Vakilifard, Plasma-sprayed Nanostructured YSZ Thermal Barrier Coatings: Thermal Insulation Capability and Adhesion Strength, Ceram. Int., 2017, 43(12), p 8556-8563

L. Guo, M. Li, Y. Zhang, and F. Ye, Improved Toughness and Thermal Expansion of Non-stoichiometry Gd2−xZr2+xO7+x/2 Ceramics for Thermal Barrier Coating Application, J. Mater. Sci. Technol., 2016, 32(1), p 28-33

P. Ctibor, R.C. Seshadri, J. Henych, V. Nehasil, Z. Pala, and J. Kotlan, Photocatalytic and Electrochemical Properties of Single-and Multi-layer Sub-stoichiometric Titanium Oxide Coatings Prepared by Atmospheric Plasma Spraying, J. Adv. Ceram., 2016, 5(2), p 126-136

B. Bernard, A. Quet, L. Bianchi, A. Joulia, A. Malié, V. Schick, and B. Remy, Thermal Insulation Properties of YSZ Coatings: Suspension Plasma Spraying (SPS) Versus Electron Beam Physical Vapor Deposition (EB-PVD) and Atmospheric Plasma Spraying (APS), Surf. Coat. Technol., 2017, 318, p 122-128

M. Gupta, N. Markocsan, X.H. Li, and L. Östergren, Influence of Bondcoat Spray Process on Lifetime of Suspension Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2018, 27(1-2), p 84-97

W.W. Zhang, G.R. Li, Q. Zhang, and G.J. Yang, Multiscale Pores in TBCs for Lower Thermal Conductivity, J. Therm. Spray Technol., 2017, 26(6), p 1183-1197

E.C. Hammel, O.L.R. Ighodaro, and O.I. Okoli, Processing and Properties of Advanced Porous Ceramics: An Application Based Review, Ceram. Int., 2014, 40(10), p 15351-15370

J. Medřický, N. Curry, Z. Pala, M. Vilemova, T. Chraska, J. Johansson, and N. Markocsan, Optimization of High Porosity Thermal Barrier Coatings Generated with a Porosity Former, J. Therm. Spray Technol., 2015, 24(4), p 622-628

M. Arai and T. Suidzu, Porous Ceramic Coating for Transpiration Cooling of Gas Turbine Blade, J. Therm. Spray Technol., 2013, 22(5), p 690-698

M. Cuglietta, J. Kuhn, and O. Kesler, A Novel Hybrid Axial-radial Atmospheric Plasma Spraying Technique for the Fabrication of Solid Oxide Fuel Cell Anodes Containing Cu Co, Ni, and Samaria-Doped Ceria, J. Therm. Spray Technol., 2013, 22(5), p 609-621

E.F. Krivoshapkina, P.V. Krivoshapkin, and A.A. Vedyagin, Synthesis of Al2O3-SiO2-MgO Ceramics with Hierarchical Porous Structure, J. Adv. Ceram., 2017, 6(1), p 11-19

B. Basnet, N. Sarkar, J.G. Park, S. Mazumder, and I.J. Kim, Al2O3-TiO2/ZrO2-SiO2 Based Porous Ceramics from Particle-Stabilized Wet Foam, J. Adv. Ceram., 2017, 6(2), p 129-138

W.W. Zhang, G.R. Li, Q. Zhang, and G.J. Yang, Bimodal TBCs with Low Thermal Conductivity Deposited by a Powder-suspension Co-spray Process, J. Mater. Sci. Technol., 2018, 34(8), p 1293-1304

S. Björklund, S. Goel, and S. Joshi, Function-dependent Coating Architectures by Hybrid Powder-Suspension Plasma Spraying: Injector Design, Processing and Concept Validation, Mater. Design, 2018, 142, p 56-65

B. Cheng, Y.M. Zhang, N. Yang, M. Zhang, L. Chen, G.J. Yang, and C.J. Li, Sintering-Induced Delamination of Thermal Barrier Coatings by Gradient Thermal Cyclic Test, J. Am. Ceram. Soc., 2017, 100(5), p 1820-1830

S. Paul, Stiffness of Plasma Sprayed Thermal Barrier Coatings, Coatings, 2017, 7(5), p 68-89

J. Ilavsky, G.G. Long, A.J. Allen, and C.C. Berndt, Evolution of the Void Structure in Plasma-Sprayed YSZ Deposits During Heating, Mater. Sci. Eng., A, 1999, 272(1), p 215-221

M. Ahrens, R. Vaßen, D. Stöver, and S. Lampenscherf, Sintering and Creep Processes in Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2004, 13(3), p 432-442

D. Basu, C. Funke, and R.W. Steinbrech, Effect of Heat Treatment on Elastic Properties of Separated Thermal Barrier Coatings, J. Mater. Res., 1999, 14(12), p 4643-4650

M. Shinozaki, T.W. Clyne, and A. Methodology, Based on Sintering-Induced Stiffening, for Prediction of the Spallation Lifetime of Plasma-Sprayed Coatings, Acta Mater., 2013, 61(2), p 579-588

D. Zhu and R.A. Miller, Thermal Conductivity and Elastic Modulus Evolution of Thermal Barrier Coatings under High Heat Flux Conditions, J. Therm. Spray Technol., 2000, 9(2), p 175-180

J. Wu, H. Guo, L. Zhou, L. Wang, and S.K. Gong, Microstructure and Thermal Properties of Plasma Sprayed Thermal Barrier Coatings From Nanostructured YSZ, J. Therm. Spray Technol., 2010, 19(6), p 1186-1194

E.H. Jordan, C. Jiang, J. Roth, and M. Gell, Low Thermal Conductivity Yttria-Stabilized Zirconia Thermal Barrier Coatings Using the Solution Precursor Plasma Spray Process, J. Therm. Spray Technol., 2014, 23(5), p 849-859

S.V. Joshi and G. Sivakumar, Hybrid Processing with Powders and Solutions: A Novel Approach to Deposit Composite Coatings, J. Therm. Spray Technol., 2015, 24(7), p 1166-1186

S.V. Joshi, G. Sivakumar, T. Raghuveer, and R.O. Dusane, Hybrid Plasma-Sprayed Thermal Barrier Coatings using Powder and Solution Precursor Feedstock, J. Therm. Spray Technol., 2014, 23(4), p 616-624

K. Matsui, A. Matsumoto, M. Uehara, N. Enomoto, and J. Hojo, Sintering Kinetics at Isothermal Shrinkage: Effect of Specific Surface Area on the Initial Sintering Stage of Fine Zirconia Powder, J. Am. Ceram. Soc., 2007, 90(1), p 44-49

O. Racek, C.C. Berndt, D.N. Guru, and J. Heberlein, Nanostructured and Conventional YSZ Coatings Deposited Using APS and TTPR Techniques, Surf. Coat. Tech., 2006, 201(1-2), p 338-346

Y. Bai, L. Zhao, J.J. Tang, S.Q. Ma, C.H. Ding, J.F. Yang, L. Yu, and Z.H. Han, Influence of Original Powders on the Microstructure and Properties of Thermal Barrier Coatings Deposited by Supersonic Atmospheric Plasma Spraying, Part II: Properties, Ceram. Int., 2013, 39(4), p 4437-4448

R.S. Lima and B.R. Marple, Toward Highly Sintering-Resistant Nanostructured ZrO 2-7 wt.% Y2O3 Coatings for TBC Applications by Employing Differential Sintering, J. Therm. Spray Technol., 2008, 17(5-6), p 846-852

G.R. Li, G.J. Yang, C.X. Li, and C.J. Li, A Comprehensive Mechanism for the Sintering of Plasma-Sprayed Nanostructured Thermal Barrier Coatings, Ceram. Int., 2017, 43(13), p 9600-9615

G. Antou, F. Hlawka, A. Cornet, C. Becker, D. Ruch, and A. Riche, In Situ Laser Remelted Thermal Barrier Coatings: Thermophysical Properties, Surf. Coat. Technol., 2006, 200(20), p 6062-6072

R.E. Taylor, X. Wang, and X. Xu, Thermophysical Properties of Thermal Barrier Coatings, Surf. Coat. Technol., 1999, 120, p 89-95

H. Wang and R.B. Dinwiddie, Reliability of Laser Flash Thermal Diffusivity Measurements of the Thermal Barrier Coatings, J. Therm. Spray Technol., 2000, 9(2), p 210-214

Q. Yu, A. Rauf, N. Wang, and C. Zhou, Thermal Properties of Plasma-Sprayed Thermal Barrier Coating with Bimodal Structure, Ceram. Int., 2011, 37(3), p 1093-1099

S. Paul, A. Cipitria, S.A. Tsipas, and T.W. Clyne, Sintering Characteristics of Plasma Sprayed Zirconia Coatings Containing Different Stabilizers, Surf. Coat. Tech., 2009, 203(8), p 1069-1074

F. Cernuschi, P.G. Bison, S. Marinetti, and P. Scardi, Thermophysical Mechanical and Microstructural Characterization of Aged Free-Standing Plasma-Sprayed Zirconia Coatings, Acta Mater., 2008, 56(16), p 4477-4488

G.R. Li, H. Xie, G.J. Yang, G. Liu, C.X. Li, and C.J. Li, A Comprehensive Sintering Mechanism for TBCs-Part I: An Overall Evolution with Two-stage Kinetics, J. Am. Ceram. Soc., 2017, 100(5), p 2176-2189

G.R. Li, H. Xie, G.J. Yang, G. Liu, C.X. Li, and C.J. Li, A Comprehensive Sintering Mechanism for TBCs-Part II: Multiscale Multipoint Interconnection-Enhanced Initial Kinetics, J. Am. Ceram. Soc., 2017, 100(9), p 4240-4251

G.R. Li, G.J. Yang, C.X. Li, and C.J. Li, A Comprehensive Sintering Mechanism for Thermal Barrier Coatings-Part III: Substrate Constraint Effect on Healing of 2D Pores, J. Am. Ceram. Soc., 2018, 101(8), p 3636-3648

G.R. Li, J. Lei, G.J. Yang, C.X.Li Li, and C.J. Li, Substrate-Constrained Effect on the Stiffening Behavior of Lamellar Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2018, 38(6), p 2579-2587

G.R. Li, G.J. Yang, C.X. Li, and C.J. Li, Sintering Characteristics of Plasma-Sprayed TBCs: Experimental Analysis and An Overall Modeling, Ceram. Int., 2018, 44(3), p 2982-2990

D.R. Clarke and S.R. Phillpot, Thermal Barrier Coating Materials, Mater. Today, 2005, 8(6), p 22-29

R. Dutton, R. Wheeler, K.S. Ravichandran, and K. An, Effect of Heat Treatment on the Thermal Conductivity of Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2000, 9(2), p 204-209

N. Wang, C. Zhou, S. Gong, and H. Xu, Heat Treatment of Nanostructured Thermal Barrier Coating, Ceram. Int., 2007, 33(6), p 1075-1081

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, WW., Li, GR., Zhang, Q. et al. Self-Enhancing Thermal Insulation Performance of Bimodal-Structured Thermal Barrier Coating. J Therm Spray Tech 27, 1064–1075 (2018). https://doi.org/10.1007/s11666-018-0754-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0754-7