Abstract

The performance of MCrAlY (M = Ni, Co) bondcoats for atmospheric plasma-sprayed thermal barrier coatings (APS-TBCs) is substantially affected by the contents of Co, Ni, Cr, and Al as well as minor additions of Y, Hf, Zr, etc., but also by manufacturing-related properties such as coating thickness, porosity, surface roughness, and oxygen content. The latter properties depend in turn on the exact technology and set of parameters used for bondcoat deposition. The well-established LPPS process competes nowadays with alternative technologies such as HVOF and APS. In addition, new technologies have been developed for bondcoats manufacturing such as high-velocity APS or a combination of HVOF and APS for application of a flashcoat. Future developments of the bondcoat systems will likely include optimization of thermal spraying methods for obtaining complex bondcoat roughness profiles required for extended APS-TBC lifetimes. Introduction of the newest generation single-crystal superalloys possessing low Cr and high Al and refractory metals (Re, Ru) contents will require definition of new bondcoat compositions and/or multilayered bondcoats to minimize interdiffusion issues. The developments of new bondcoat compositions may be substantially facilitated using thermodynamic–kinetic modeling, the vast potential of which has been demonstrated in recent years.

Similar content being viewed by others

References

G.W. Goward, Progress in Coatings for Gas Turbine Airfoils, Surf. Coat. Technol., 1998, 108-109(1-3), p 73-79

B. Gleeson, Thermal Barrier Coatings for Aeroengine Applications, J. Propuls. Power, 2006, 22-2, p 375-383

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater. Sci., 2001, 46, p 505-553

W.J. Quadakkers, A.K. Tyagi, D. Clemens, R. Anton, ans L. Singheiser, in The Significance of Bond Coat Oxidation for the Life of TBC Coatings, Elevated Temperature Coatings Science and Technology III, eds. by J.M. Hampikian, N.B. Dahotre, The Minerals, Metals & Materials Society (TMS), Warrendale, Pennsylvania, 1999, p 119-130

P. Fox and G.J. Tatlock, Effect of Tantalum Additions on Oxidation of Overlay Coated Superalloys, Mater. Sci. Technol., 1989, 5, p 816

N. Czech, F. Schmitz, and W. Stamm, Improvement of MCrAlY coatings by addition of rhenium, Surf. Coat. Technol., 1994, 68-69, p 17

U. Täck, The Influence of Cobalt and Rhenium on the Behaviour of MCrAlY Coatings (Ph.D. thesis) Tech. Univ. Freiberg, (2004) 25, 151, 169

ASM Binary Alloy Phase Diagrams, ASM International, 1996

C. Lechner and J. Seume, Ed., Stationaere Gasturbinen, Springer, Berlin, 2003, p 749

D.R.G. Achar, R. Munoz-Arroyo, L. Singheiser, and W.J. Quadakkers, Modelling of Phase Equilibria in MCrAlY Coating Systems, Surf. Coat. Technol., 2004, 187, p 272-283

R. Muñoz-Arroyo, D. Clemens, F. Tietz, R. Anton, J. Quadakkers, and L. Singheiser, Influence of Composition and Phase Distribution on the Oxidation Behaviour of NiCoCrAlY Alloys, Mater. Sci. Forum, 2001, 369-372, p 165

J. Toscano, A. Gil, T. Hüttel, E. Wessel, D. Naumenko, L. Singheiser, and W.J. Quadakkers, Temperature Dependence of Phase Relationships in Different Types of MCrAlY-Coatings, Surf. Coat. Technol., 2007, 202, p 603-607

A. Taylor and R. W. Floyd: The Constitution of Nickel-Rich Alloys of the Nickel-Chromium-Alumium System, J. Inst. Metals, 81, 45 (1952-1953)

R. Munoz-Arroyo, Ph.D. thesis, University of Madrid, Spain (2003)

B. Jansson, M. Schalin, M. Selleby, and B. Sundman, in The ThermoCalc database system, eds. by C.W. Bale, G.A. Irons, Computer Software in Chemical and Extractive Metallurgy, The Metallurgical Society of Canadian Institute of Mining, Metallurgy and Petroleum, Quebec, 1993, p 57

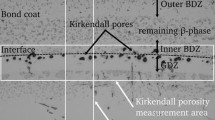

R. Pillai, W.G. Sloof, A. Chyrkin, L. Singheiser, and W.J. Quadakkers, A New Computational Approach for Modelling the Microstructural Evolution And Residual Lifetime Assessment of MCrAlY Coatings, Mater. High Temp., 2015, 32(1-2), p 57-67

P. Song, Influence of Material and Testing Parameters on the Lifetime of TBC Systems with MCrAlY and NiPtAl Bondcoats, Ph.D. Thesis, RWTH Aachen University (2011)

A. Chyrkin, unpublished results, Forschungszentrum Jülich GmbH (2012), presented at International Conference on Metallurgical Coatings and Thin Films (ICMCTF 2012) San Diego, CA, USA, 23 Apr 2012, Presentation Title: Compositional and Microstructural Changes in MCrAlY Coatings Due to Interdiffusion with the Base Material

A. Borgenstam, A. Engstrom, L. Hoglund, and J. Agren, J. Phase Equilibr., 2000, 21, p 269

R. Anton, Untersuchungen zu den Versagensmechanismen von Wärmedämmschicht-Systemen im Temperaturbereich von 900 °C bis 1050 °C bei zyklischer Temperaturbelastung, Ph.D. Thesis, University of Aachen (2001), pp. 37-54

D. Shifler, Meeting Materials Needs in Extreme Naval Corrosive and Oxidative Environments, Mater. High Temp., 2015, 32(1-2), p 148-159

C. Duhamel, M. Chieux, R. Molins, L. Remy, D. Monceau, A. Vande Put, and J.Y. Guedouc, Thermal Cycling Behaviour of Thermal Barrier Coating Systems Based on First- and Fourth Generation Ni-Based Superalloys, Mater. High Temp., 2012, 29(2), p 136-144

J. Toscano, R. Vaßen, A. Gil, M. Subanovic, D. Naumenko, L. Singheiser, and W.J. Quadakkers, Parameters Affecting TGO Growth and Adherence on MCrAlY-Bond Coats for TBC’s, Surf. Coat. Technol., 2006, 201, p 3906-3910

W. Nowak, High Temperature Corrosion of Alloys and Coatings in Gas-Turbines Fired with Hydrogen-Rich Syngas Fuels, Ph.D. Thesis, RWTH Aachen University (2014)

J. Toscano, Influence of Composition and Processing on the Oxidation Behavior of MCrAlY-Coatings for TBC Applications, Ph.D. Thesis, RWTH Aachen University (2008)

H. Echsler, D. Renusch, and M. Schütze, Bond Coat Oxidation and its Significance for Life Expectancy of Thermal Barrier Coatings, Mater. Sci. Technol., 2004, 20, p 307-317

D. Naumenko, V. Shemet, L. Singheiser, and W.J. Quadakkers, Failure Mechanisms of Thermal Barrier Coatings on MCrAlY-Type Bondcoats Associated with the Formation of the Thermally Grown Oxide, J. Mater. Sci., 2009, 44(7), p 1687-1703

D. Naumenko, B.A. Pint, and W.J. Quadakkers, Current Thoughts on Reactive Element Effects in Alumina-Forming Systems: In Memory of John Stringer, Oxid. Met., 2016, 86(1), p 1-43

P.K. Wright and A.G. Evans, Mechanisms Governing the Performance of Thermal Barrier Coatings, Curr. Opin. Solid State Mater. Sci., 1999, 4, p 255-265

H.E. Evans and M.P. Taylor, Diffusion Cells and Chemical Failure of MCrAlY Bond Coats in Thermal-Barrier Coating Systems, Oxid. Met., 2001, 55(1/2), p 17-34

M. Subanovic, D. Sebold, R. Vassen, E. Wessel, D. Naumenko, L. Singheiser, and W.J. Quadakkers, Effect of Manufacturing Related Parameters on Oxidation Properties of MCrAlY Bondcoats, Mater. Corros., 2008, 59(6), p 463-470

T.B. Massalski, ASM Binary Phase Diagrams, ASM International, Materials Park, 1996

A. Gil, V. Shemet, R. Vassen, M. Subanovic, J. Toscano, D. Naumenko, L. Singheiser, and W.J. Quadakkers, The Effect of Surface Condition on the Oxidation Behaviour of MCrAlY Coatings, Surf. Coat. Technol., 2006, 201, p 3824-3828

P. Song, D. Naumenko, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Oxygen Content in NiCoCrAlY Bondcoat On The Lifetimes of EB-PVD and APS Thermal Barrier Coatings, Surf. Coat. Technol., 2013, 221, p 207-213

M. Subanovic, Einfluss der Bondcoatzusammensetzung und Herstellungsparameter auf die Lebensdauer von Wärmedämmschichten bei zyklischer Temperaturbelastung, Ph.D. Thesis RWTH Aachen University (2008)

I. Keller, D. Naumenko, W.J. Quadakkers, R. Vaßen, and L. Singheiser, Influence of Vacuum Heat Treatment Parameters on the Surface Composition of MCrAlY Coatings, Surf. Coat. Technol., 2013, 215, p 24-29

A. Gil, D. Naumenko, R. Vassen, J. Toscano, M. Subanovic, L. Singheiser, and W.J. Quadakkers, Y-rich Oxide Distribution in Plasma Sprayed MCrAlY-Coatings Studied by SEM with a Cathodoluminescence Detector and Raman Spectroscopy, Surf. Coat. Technol., 2009, 204, p 531-538

M. Ahrens, R. Vassen, and D. Stover, Surf. Coat. Technol., 2002, 161, p 26-35

J.A. Haynes, K.A. Unocic, and B.A. Pint, Effect of Water Vapor on the 1100 C Oxidation Behavior of Plasma Sprayed TBCs with HVOF NiCoCrAlX Bond Coatings, Surf. Coat. Technol., 2013, 215, p 39-45

R. Eriksson, S. Sjöström, H. Brodin, S. Johansson, L. Östergren, and X.-H. Li, TBC Bond Coat–Top Coat Interface Roughness: Influence on Fatigue Life and Modelling Aspects, Surf. Coat. Technol., 2013, 236, p 230-238

J.A. Haynes, K.A. Unocic, M.J. Lance, and B.A. Pint, Impact of Superalloy Composition, Bondcoat Roughness and Water Vapor on TBC Lifetime with HVOF NiCoCrAlYHfSi bond coatings, Surf. Coat. Technol., 2013, 237, p 65-70

A. Feuerstein, J. Knapp, T. Taylor, A. Ashary, A. Bolcavage, and N. Hitchman, Technical and Economical Aspects of Current Thermal Barrieer Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review, J. Therm. Spray Technol., 2008, 17(2), p 199-213

B. Rajasekaran, G. Mauer, and R. Vassen, Enhanced Characteristics of HVOF-Sprayed MCrAlY Bond Coats for TBC Applications, J. Therm. Spray Technol., 2011, 20(6), p 1209-1216

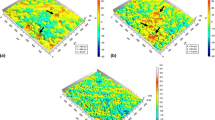

W. Nowak, D. Naumenko, G. Mor, F. Mor, D.E. Mack, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Processing Parameters on MCrAlY Bondcoat Roughness and Lifetime of APS–TBC Systems, Surf. Coat. Technol., 2014, 260, p 82-89

M.A. Helminiak, N.M. Yanar, F.S. Pettit, T.A. Taylor, and G.H. Meier, The Behaviour of High-Purity, Low-Density Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Tech., 2009, 204, p 793-796

G. Mauer, D. Sebold, and R. Vaßen, MCrAlY Bondcoats by High-Velocity Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2014, 23(1-2), p 140-146

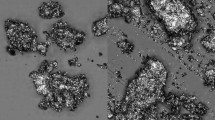

G. Mauer, D. Sebold, R. Vassen, O. Guillon, E. Hejrani, D. Naumenko, and W.J. Quadakkers, Impact of Processing Conditions and Feedstock Characteristics on Thermally Sprayed MCrAlY Bondcoat Properties, Surf. Coat. Technol., 2016. https://doi.org/10.1016/j.surfcoat.2016.08.079

E. Hejrani, D. Sebold, W.J. Nowak, G. Mauer, D. Naumenko, R. Vaßen, and W.J. Quadakkers, Isothermal and Cyclic Oxidation Behavior of Free Standing MCrAlY Coatings Manufactured by High-Velocity Atmospheric Plasma Spraying, Surf. Coat. Technol., 2017, 313, p 191-201

T. Huang, J. Bergholz, G. Mauer, R. Vassen, D. Naumenko, and W.J. Quadakkers, Effect of Test Atmosphere Composition on High-Temperature Oxidation Behaviour of CoNiCrAlY Coatings Produced from Conventional and ODS Powders, Mater. High Temp., 2017. https://doi.org/10.1080/09603409.2017.1389422

P. Richer, M. Yandouzi, L. Beauvais, and B. Jodoin, Oxidation behaviour of CoNiCrAlY bond coats produced by plasma, HVOF and Cold Gas Dynamic Spraying, Surf. Coat. Technol., 2010, 204(24), p 3962-3974

Yong Li, Chang-Jiu Li, Qiang Zhang, Lu-Kuo Xing, and Guan-Jun Yang, Effect of Chemical Compositions and Surface Morphologies of MCrAlY Coating on Its Isothermal Oxidation Behavior, J. Therm. Spray Technol., 2011, 20(1), p 121-131

Y. Zhang, Electrodeposited MCrAlY Coatings for Gas Turbine Engine Applications, JOM, 2015, 67(11), p 2599-2607

G. Wydra et al., Method to produce a slip layer, which is resistant to corrosion and oxidation, United States Patent N0.: US 6,440,499 B1, Date of Patent: Aug. 27, 2002

Hasz et al. Method for Applying a high-temperature bondcoat on a metal substrate and related compositions and articles, United States Patent N0.2 US 6,497,758 B1, Date of Patent: Dec. 24, 2002

L. Ajdelsztajn, F. Tang, J.M. Schoenung, G.E. Kim, and V. Provenzano, Synthesis and Oxidation Behavior of Nanocrystalline MCrAlY Bond Coatings, J. Therm. Spray Technol., 2005, 14(1), p 23-30

Acknowledgments

The authors are grateful to the following colleagues in the Institute for Energy and Climate Research of the Forschungszentrum Jülich for assistance in the coatings procurement, experimental and analytical work, and fruitful discussions: H. Cosler, A. Kick, E. Wessel, D. Grüner, V. Gutzeit, M. Subanovic, J. Toscano, I. Keller, P. Song, W. Nowak, T. Huang, E. Hejrani, A. Jalowicka, R. Vassen, D. Mack, G. Mauer, D. Sebold, J. Bergholz. The authors acknowledge partial funding of this work by the German Research Foundation (DFG) under the Grant No. NA-615-2 and the European Union (R&D Project H2-IGCC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naumenko, D., Pillai, R., Chyrkin, A. et al. Overview on Recent Developments of Bondcoats for Plasma-Sprayed Thermal Barrier Coatings. J Therm Spray Tech 26, 1743–1757 (2017). https://doi.org/10.1007/s11666-017-0649-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0649-z