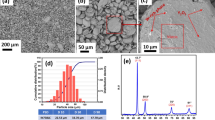

A MoSi2-ZrB2 coating was prepared on SiC-coated C/C composites by supersonic plasma spraying, and the effects of particle diameter and subsequent heat treatment in argon at different temperatures on the adhesion strength were studied. The results show that the MoSi2-ZrB2 coating sprayed with an average powder diameter of 29.2 μm could melt thoroughly and form a dense structure without micro-pore, which results in a relatively good adhesion strength of 11.4 MPa compared with 9.2 and 8.6 MPa of the coatings sprayed with the powder diameter of 58.2 and 35.5 μm. The coating presents a decreasing porosity from 2.2 to 1.5% and an increasing adhesion strength from 11.6 to 16.9 MPa after heat treatment at 800 °C, which is mainly caused by slight sintering of SiO2 and B2O3

Similar content being viewed by others

References

N.S. Jacobson and D.M. Curry, Oxidation Microstructure Studies of Reinforced Carbon/Carbon, Carbon, 2006, 44(7), p 1142-1150

Y.L. Zhang, F. Tian, W.Y. Zeng, B.X. Yang, H.J. Li, and K.Z. Li, Microstructure and Oxidation Behavior of C/C-ZrB2-SiC Composites Coated with SiC Coating at High Temperature, Corr. Sci., 2015, 100, p 421-427

D. Sciti, M. Brach, and A. Bellosi, Oxidation Behavior of a Pressureless Sintered ZrB2-MoSi2 Ceramic Composite, Mater. Res. Soc., 2005, 20(4), p 922-930

J. Rodríguez-Sánchez, E. Sánchez-González, F. Guiberteau, and A.L. Ortiz, Contact-Mechanical Properties at Intermediate Temperatures of ZrB2 Ultra-High-Temperature Ceramics Pressureless Sintered with Mo, Ta, or Zr Disilicides, J. Eur. Ceram. Soc., 2015, 35(11), p 3179-3185

X.R.X. Ren, H.J. Li, and Y.H. Chu, Preparation of Oxidation Protective ZrB2-SiC Coating by In Situ Reaction Method on SiC-coated Carbon/Carbon Composites, Surf. Coat. Technol., 2014, 247, p 61-67

X.Y. Yao, H.J. Li, Y.L. Zhang, and Y.J. Zhang, Oxidation and Mechanical Properties of SiC/SiC-MoSi2-ZrB2 Coatings for Coating for Carbon/Carbon Composites, J. Mater. Sci. Technol., 2014, 30(2), p 123-127

J.Y. Mao, M. Liu, and J. Mao, Oxidation-resistance of ZrB2-MoSi2 Composite Coatings Prepared by Atmospheric Plasma Spraying, J. Inorg. Mater, 2015, 39(3), p 282-286

B.L. Zou, Y. Hui, and W.Z. Huang, Oxidation Protection of Carbon/Carbon Composites with a Plasma-Sprayed ZrB2-SiC-Si/Yb2SiO5/LaMgAl11O19 Coating During Thermal Cycling, J. Eur. Ceram. Soc., 2015, 35(7), p 2017-2025

Y.L. Zhang, Z.X. Hu, B.X. Yang, J.C. Ren, and H.J. Li, Effect of Pre-oxidation on the Ablation Resistance of ZrB2-SiC Coating for SiC-Coated Carbon/Carbon Composites, Ceram. Int., 2015, 41(2), p 2582-2589

L.F. Pierre, V.R. Joachim and I.B. Maher: Thermal Spray Fundamentals, 2013, p 943–944

Y. Bai, L. Zhao, Y.M. Qu, Q.Q. Fu, Y. Wang, K. Liu, J.J. Tang, B.Q. Li, and Z.H. Han, Particle In-Flight Behavior and its Influence on the Microstructure and Properties of Supersonic- Atmospheric- Plasma- Sprayed Nanostructured Thermal Barrier Coatings, J. Alloy. Compd., 2015, 644, p 873-882

K. Liu, J.J. Tang, Y. Bai, Q.Z. Yang, Y. Wang, Y.X. Kang, L. Zhao, P. Zhang, and Z.H. Han, Particle In-Flight Behavior and its Influence on the Microstructure and Mechanical Property of Plasma Sprayed La2Ce2O7 Thermal Barrier Coatings, Mater. Sci. Eng., A, 2015, 625, p 177-185

N. Prashant, G. Sivakumar, and K. Sudarshan, Solution Precursor Plasma Spray (SPPS) Technique of Catalyst Coating for Hydrogen Production in a Single Channel with Cavities Plate Type Methanol Based Microreformer, Chem. Eng. J., 2015, 277, p 168-175

B. Vautherin, M.P. Planche, and G. Montavon, Study of Metallic Powder Behavior in Very Low Pressure Plasma Spraying (VLPPS)—Application to the Manufacturing of Titanium-Aluminum Coatings, Surf. Coat. Technol., 2015, 275, p 341-348

F. Azarmi, Vaccum Plasma Spraying, Adv. Mater. Process., 2005, 163(8), p 37-39

S. Paul, A. Cipitria, I.O. Golosnoy, L. Xie, M.R. Dorfman and T.W. Clyne J, Effects of Impurity Content on the Sintering Characteristics of Plasma-Sprayed Zirconia, Therm. Spray Technol., 2007, 16(5–6), p 798–803

M. Hadad, G. Marot, P. Démarécaux, D. Chicot, J. Lesage, L. Rohr and S. Siegmann, Adhesion Tests for Thermal Spray Coatings: Correlation of Bond Strength and Interfacial Toughness, Surf. Eng., 2007, 23(3), p 279–283

F. Ghadami, M. Heydarzadeh Sohi, and S. Ghadami, Effect of Bond Coat and Post-heat Treatment on the Adhesion of Air Plasma Sprayed WC-Co Coatings, Surf. Coat. Technol., 2015, 261, p 289-294

C.C. Berndt, The Adhesion of Flame and Plasma Sprayed Coatings, Monash University (1980)

Q.G. Fu, H.J. Li, X.H. Shi, K.Z Li and G.D. Sun, Silicon Carbide Coating to Protect Carbon/Carbon Composites Against Oxidation, Script. Mater., 2005, 52(9), p 923–927

Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, ASTM Standard C633–79, American Society for Testing and Materials, Philadelphia, PA, 1999

E. Eakins, D.D. Jayaseelan, and W.E. Lee, Towards Oxidation-Resistant ZrB2–SiC Ultrahigh Temperature Ceramics, Metall. Mater. Trans. A, 2011, 42(4), p 878-887

Z. Derelioglu, A.L. Carabat, G.M. Song, S. van der Zwaag, and W.G. Sloof, On the Use of B-alloyed MoSi2 Particles a Crack Healing Agents in Yttria Stabilized Zirconia Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2015, 35, p 4507-4511

Acknowledgments

This work has been supported by 111 project (Grant No. B08040) and National Natural Science Foundation of China (Grant Nos. 51521061, 51572223 and 51272212), Project supported by the Research Fund of the State Key Laboratory of Solidification Processing (NWPU), China (Grant No. 142-TZ-2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, W., Qian-gang, F., Ning-kun, L. et al. Improvement of the Adhesion Strength of MoSi2-ZrB2 Coating by Optimizing Particle Spraying and Subsequent Heat Treatment. J Therm Spray Tech 25, 1280–1288 (2016). https://doi.org/10.1007/s11666-016-0456-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0456-y