Abstract

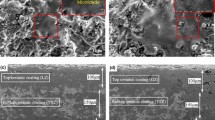

In this study, the effects of intrinsic feature of microstructure in thermal barrier coatings (TBCs) with and without vertical cracks on the microstructure and mechanical properties were investigated in cyclic thermal exposure. The hardness values of TBCs with vertical cracks were higher than those without vertical cracks, showing a good agreement with microstructure. The TBC prepared without vertical cracks using the 204-NS was delaminated after 250 cycles in the cyclic thermal exposure test. The TBCs with and without vertical cracks prepared with 204 C-NS and the TBC with vertical cracks prepared with 204 NS showed a sound condition without any cracking at the interface or spalling of top coat. After the thermal exposure of 381 cycles, the hardness values were increased in the survived TBC specimens, and the thicknesses of TGO layer for the TBCs with 204 C-NS and 204 NS were measured as in the ranges of 5-9 and 3-7 μm, respectively. In the thermal shock test, the advantage of vertical cracks for thermal durability of TBC could be well investigated, showing relatively longer sustained cycles in the TBCs with vertical cracks. The TBCs with vertical cracks are more efficient in improving thermal durability than those without vertical cracks in cyclic thermal exposure.

Similar content being viewed by others

References

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater. Sci., 2001, 46, p 505-553

N.R. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296, p 280-284

J.H. Zaat, A Quarter of Century of Plasma Spraying, Annu. Rev. Mater. Sci., 1983, 13, p 9-42

D.R. Clarke and S.R. Phillport, Thermal Barrier Coating Materials, Mater. Today, 2005, 8(6), p 22-29

J.Y. Kwon, J.H. Lee, Y.G. Jung, and U. Paik, Effect of Bond Coat Nature and Thickness on Mechanical Characteristic and Contact Damage of Zirconia-Based Thermal Barrier Coatings, Surf. Coat. Technol., 2006, 201, p 3483-3490

J.Y. Kwon, J.H. Lee, H.C. Kim, Y.G. Jung, U. Paik, and K.S. Lee, Effect of Thermal Fatigue on Mechanical Characteristics and Contact Damage of Zirconia-Based Thermal Barrier Coatings with HVOF-Sprayed Bond Coat, Mater. Sci. Eng. A, 2006, 429, p 173-180

D.R. Clarke and C.G. Levi, Materials Design for the Next Generation Thermal Barrier Coating, Annu. Rev. Mater. Res., 2003, 33, p 383-417

H.-J. Rätzer-Scheibe, U. Schulz, and T. Krell, The Effect of Coating Thickness on the Thermal Conductivity of EB-PVD PYSZ Thermal Barrier Coatings, Surf. Coat. Technol., 2006, 201, p 5636-5644

J.R. Nicholls, K.J. Lawson, A. Johnstone, and D.S. Rickerby, Methods to Reduce the Thermal Conductivity of EB-PVD TBCs, Surf. Coat. Technol., 2002, 151-152, p 383-391

K. Richardt, K. Bobzin, D. Sporer, T. Schläfer, and P. Fiala, Tailor-Made Coatings for Turbine Applications Using the Triplex Pro 200, J. Therm. Spray Technol., 2008, 17, p 612-616

X.Q. Cao, R. Vassenb, and D. Stoeverb, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1-10

R. Dutton, R. Wheeler, K.S. Ravichandran, and K. An, Effect of Heat Treatment on the Thermal Conductivity of Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2000, 9, p 204-209

T. Bhatia, A. Ozturk, L. Xie, E.H. Jordan, B.M. Cetegen, M. Gell, X. Ma, and N.P. Padture, Mechanisms of Ceramic Coating Deposition in Solution-Precursor Plasma Spray, J. Mater. Res., 2002, 17, p 2363-2372

W. Schlichting, N.P. Padture, E.H. Jordan, and M. Gell, Failure Modes in Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng. A, 2003, 342, p 120-130

A. Rabiei and A.G. Evans, Failure Mechanism Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48, p 3963-3976

T.A. Talyor, US Patent No. 5073433, 1991

A.D. Jadhav, N.P. Padture, E.H. Jordan, M. Gell, P. Miranzo, and E.R. Fuller, Jr., Low-Thermal-Conductivity Plasma-Sprayed Thermal Barrier Coatings with Engineered Microstructures, Acta Mater., 2006, 54, p 3343-3349

A. Jadhav, N.P. Padture, F. Wu, E.H. Jordan, and M. Gell, Thick Ceramic Thermal Barrier Coatings with High Durability Deposited Using Solution-Precursor Plasma Spray, Mater. Sci. Eng. A, 2005, 405, p 313-320

T.A. Taylor, D.L. Appleby, A.E. Weatherill, and J. Griffiths, Plasma-Sprayed Yttria-Stabilized Zirconia Coatings: Structure-Property Relationships, Surf. Coat. Technol., 1990, 43-44, p 470-480

Y.H. Sohn, E.Y. Lee, B.A. Nagaraj, R.R. Biederman, and R.D. Sisson, Jr., Microstructural Characterization of Thermal Barrier Coatings on High Pressure Turbine Blades, Surf. Coat. Technol., 2001, 146-147, p 132

M. Madhwal, E.H. Jordan, and M. Gell, Failure Mechanisms of Dense Vertically-Cracked Thermal Barrier Coatings, Mater. Sci. Eng. A, 2004, 384, p 151-161

Sulzer-Metco Thermal Spray Materials Guide, http://www.sulzermetco.com/

B.R. Lawn, Fracture of Brittle Solids, 2nd ed., Cambridge University Press, Cambridge, UK, 1993

C. Zhou, N. Wang, Z. Wang, S. Gang, and H. Xu, Thermal Cycling Life and Thermal Diffusivity of a Plasma-Sprayed Nanostructured Thermal Barrier Coating, Scripta Mater., 2004, 51, p 945-948

P.K. Panda, T.S. Kannan, J. Dubois, C. Olagnon, and G. Fantozzi, Thermal Shock and Thermal Fatigue Study of Ceramic Materials on a Newly Developed Ascending Thermal Shock Test Equipment, Sci. Technol. Adv. Mater., 2002, 3, p 327-334

S.O. Chwa and A. Ohmori, Microstructures of ZrO2-8wt.%Y2O3 Coatings Prepared by a Plasma Laser Hybrid Spraying Technique, Surf. Coat. Technol., 2002, 153, p 304-312

X.Q. Ma and M. Takemoto, Quantitative Acoustic Emission Analysis of Plasma Sprayed Thermal Barrier Coatings Subjected to Thermal Shock Tests, Mater. Sci. Eng. A, 2001, 308, p 101-110

Y. Radin and T. Kontorovich, Equivalent Operating Hours Concept for CCPP Components Reliability Evaluation, 2012 International Conference on Power Energy System, 2012, vol 13, p 175-178

GeneralCologne Re™, Power Re-View, https://www.facworld.com/WebLib.NSF/ObjectPreview/1Power2.pdf/$File/Power2.pdf

K. Ma and J.M. Schoenung, Isothermal Oxidation Behavior of Cryomilled NiCrAlY Bond Coat: Homogeneity and Growth Rate of TGO, Surf. Coat. Technol., 2011, 205, p 5178-5185

H.J. Jang, D.H. Park, Y.G. Jung, J.C. Jang, S.C. Choi, and U. Paik, Mechanical Characterization and Thermal Behavior of HVOF-Sprayed Bond Coat in Thermal Barrier Coatings (TBCs), Surf. Coat. Technol., 2006, 200, p 4355-4362

P.G. Tsantrizos, G.E. Kim, and T.A. Braezinski, TBCs on Free Standing Multilayer Components, AGARD SMP Meeting on “Thermal Barrier Coatings” (Aalberg, Denmark), 1997, p 7-1-7-8

P.H. Lee, S.-Y. Lee, J.-Y. Kwon, S.W. Myoung, J.H. Lee, Y.G. Jung, H. Cho, and U. Paik, Thermal Cycling Behavior and Interfacial Stability in Thick Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205, p 1250-1255

S.W. Myoung, J.H. Kim, W.R. Lee, Y.G. Jung, K.S. Lee, and U. Paik, Microstructure Design and Mechanical Properties of Thermal Barrier Coatings with Layered Top and Bond Coats, Surf. Coat. Technol., 2010, 205, p 1229-1235

Acknowledgments

This study was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (2012-0009450), by a grant from the Fundamental R&D Program for Core Technology of Materials funded by the Ministry of Knowledge Economy (10041233), and by the Power Generation & Electricity Delivery of the Korean Institute of Energy Technology Evaluation and Planning (KETEP) grants funded by the Korean Ministry of Knowledge Economy (2011T100200224).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Z., Myoung, SW., Kim, HS. et al. Microstructure Evolution and Interface Stability of Thermal Barrier Coatings with Vertical Type Cracks in Cyclic Thermal Exposure. J Therm Spray Tech 22, 671–679 (2013). https://doi.org/10.1007/s11666-013-9886-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9886-y