Abstract

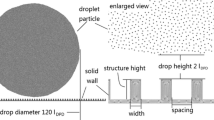

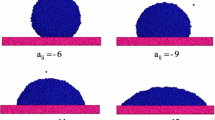

Three-dimensional molecular dynamics simulation was conducted to clarify at an atomic level the flattening process of a high-temperature droplet impacting a substrate at high speed. The droplet and the substrate were assumed to consist of pure aluminum, and the Morse potential was postulated between a pair of aluminum atoms. In this report, the influence of the impact parameters such as the droplet velocity and the droplet diameter on flattening behavior were analyzed. As a result, the following representative conclusions were obtained: (a) the flattening ratio increases in proportion to the droplet velocity and the droplet diameter; (b) the flattening ratio for nanosized droplet can be reorganized by the same dimensionless parameters of the proper physical properties, such as the viscosity and the surface tension, as those used in the macroscopic flattening process.

Similar content being viewed by others

References

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, Chichester, UK, 1995

D.B. Chrisey, G.K. Hubler, Pulsed Laser Deposition of Thin Films, John Wiley & Sons, Chichester, UK, 1994

V.I. Merkulov, D.H. Lowndes, G.E. Jellison, Jr., A.A. Puretzky, D.B. Geohegan, Structure and Optical Properties of Amorphous Diamond Films Prepared by ArF Laser Ablation as a Function of Carbon Ion Kinetic Energy, Appl. Phys. Lett., 1998, 73(18), p 2591-2593

J. Madejski, Solidification of Droplets on a Cold Surface, Int. J. Heat Mass Transfer, 1976, 19, p 1009-1013

J.P. Delplanque, R.H. Rangel, An Improved Model for Droplet Solidification on a Flat Surface, J. Mater. Sci., 1997, 32(6), p 1519-1530

M. Pasandideh-Fard, Y.M. Qiao, S. Chandra, J. Mostaghimi, Capillary Effects During Droplet Impact on a Surface, Phys. Fluids, 1996, 8(3), p 650-659

M. Pasandideh-Fard, R. Bhola, S. Chandra, J. Mostaghimi, Deposition of Tin Droplets on a Steel Plate: Simulations and Experiments, Int. J. Heat Mass Transfer, 1998, 41, p 2929-2945

H. Jones, Cooling, Freezing and Substrate Impact of Droplets Formed by Rotary Atomization, J. Phys. D, Appl. Phys., 1971, 4, p 1657-1660

G. Trapaga, J. Szekely, Mathematical Modeling of the Isothermal Impingement of Liquid Droplets in Spraying Processes, Metall. Trans., 1991, 22B, p 901-914

G. Trapaga, J. Szekely, Fluid Flow, Heat Transfer, and Solidification of Molten Metal Droplets Impinging on Substrates: Comparison of Numerical and Experimental Results, Metall. Trans., 1992, 23B, p 701-718

E. Nishioka, M. Fukumoto, Flattening Behavior of Freely Fallen Molten Metal Droplet on Flat Substrate, Quart. J. Jpn. Weld. Soc., 1998, 16(4), p 437-444

M. Fukumoto, H. Nagai, T. Yasui, Influence of Surface Character Change of Substrate Due to Heating on Flattening Behavior of Thermal Sprayed Particles, J. Therm. Spray Technol., 2006, 15(4), p 759-764

L. Li, A. Vaidya, S. Sampath, H. Xiong, L. Zheng, Particle Characterization and Splat Formation of Plasma Sprayed Zirconia, J. Thermal Spray Technol., 2006, 15(1), p 97-105

P. Fauchais, M. Fukumoto, A. Vardelle, M. Vardelle, Knowledge Concerning Splat Formation: An Invited Review, J. Thermal Spray Technol., 2004, 13(3), p 337-360

P. Gougeon, C. Moreau, Simultaneous Independent Measurement of Splat Diameter and Cooling Time During Impact on a Substrate of Plasma Sprayed Molybdenum Particles, J. Thermal Spray Technol., 2001, 10(1), p 76-82

A. McDonald, M. Lamontagne, S. Chandra, C. Moreau, Photographing Impact of Plasma-Sprayed Particles on Metal Substrates, J. Thermal Spray Technol., 2006, 15(4), p 708-716

M. Xue, S. Chandra, J. Mostaghimi, Investigation of Splat Curling up in Thermal Spray Coatings, J. Thermal Spray Technol., 2006, 15(4), p 531-536

N.Z. Mehdizadeh, M. Lamontagne, C. Moreau, S. Chandra, J. Mostaghimi, Photographing Impact of Molten Molybdenum Particles in a Plasma Spray, J. Thermal Spray Technol., 2005, 14(3), p 354-361

Y. Shibuta, S. Maruyama, Molecular Dynamics Simulation of Formation Process of Single-walled Carbon Nanotubes by CCVD Method, Chem. Phys. Lett., 2003, 382 (3-4), p 381-386

K. Tanaka, T. Kato, Y. Matsumoto, Molecular Dynamics Simulation of Vibrational Friction Force Due to Molecular Deformation in Confined Lubricant Film, ASME J. Tribol,, 2003, 125(3), p 587-591

T. Inamura, S. Shimada, N. Takezawa, N. Nakahara, Brittle/Ductile Transition Phenomena Observed in Computer Simulations of Machining Defect-Free Monocrystalline Silicon, Ann. CIRP, 1997, 46(1), p 31-34

J. Shimizu, E. Ohmura, Y. Kobayashi, S. Kiyoshima, H. Eda, Molecular Dynamics Analysis of Elementary Process of Coating by a High-Temperature, High-Speed Droplet (Flattening Process and Atomic Behavior of a Droplet), JSME (Jpn. Soc. Mech. Eng.) Int. J. Series C, 2006, 49(2), p 505-511

R.W. Hockney, The Potential Calculation and Some Applications, Meth. Comput. Phys., 1969, 9, p 135

L.A. Girifalco, V.G. Weizer, Application of the Morse Potential Function to Cubic Metals, Phys. Rev., 1959, 114, p 687-690

J. Shimizu, E. Ohmura, H. Eda, Analysis of Sliding Mechanism Using Molecular Dynamics: Friction Process, Jpn. J. Trib., 1996, 41(12), p 1375-1386

J. Farges, M.F. de Feraudy, B. Raout, G. Torchet, Noncrystalline Structure of Argon Clusters, J. Chem. Phys., 1986, 84(6) p 3491-3501

Acknowledgments

This research was partially supported by the Takahashi Industrial and Economic Research Foundation, Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2007 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Global Coating Solutions, Proceedings of the 2007 International Thermal Spray Conference, Beijing, China, May 14-16, 2007, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2007.

Rights and permissions

About this article

Cite this article

Shimizu, J., Ohmura, E., Kobayashi, Y. et al. Molecular Dynamics Simulation of Flattening Process of a High-Temperature, High-Speed Droplet—Influence of Impact Parameters. J Therm Spray Tech 16, 722–728 (2007). https://doi.org/10.1007/s11666-007-9103-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9103-y