Abstract

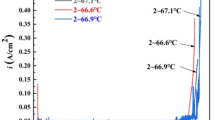

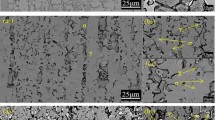

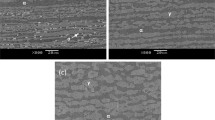

The corrosion behavior of 2507 super duplex stainless steel (SDSS) in H2S-free and H2S-containing acidic environments was investigated. In N2 environment, the dissolution of Fe was intensified with potential, resulting in the increase in the current density. The presence of H2S decreased the corrosion resistance of 2507 SDSS. As the potential rose between − 0.45 and − 0.37 V(SCE), the selective dissolution of the ferrite was declined due to the increase in the content of Cr and Fe species in the corrosion product layer. Interestingly, when the potential was above − 0.37 V(SCE), the formation of pits in the ferritic region at the phase boundary interface extended toward the ferritic region with the increasing potential under the synergistic effect of H2S.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

J. Tang, Y. Shao, J. Guo, T. Zhang, G. Meng, and F. Wang, The effect of H2S Concentration on the Corrosion Behavior of Carbon Steel at 90 °C, Corros. Sci., 2010, 52(6), p 2050–2058.

L. Wei, X. Pang, and K. Gao, Corrosion of Low Alloy Steel and Stainless Steel in Supercritical CO2/H2O/H2S Systems, Corros. Sci., 2016, 111, p 637–648.

L. Wang, Y. Dou, S. Han, J. Wu, and Z. Cui, Influence of Sulfide on the Passivation Behavior and Surface Chemistry of 2507 Super Duplex Stainless Steel in Acidified Artificial Seawater, Appl. Surf. Sci., 2020, 504, p 144340.

J.M. Shockley, D.J. Horton, and K.J. Wahl, Effect of Aging of 2507 Super Duplex Stainless Steel on Sliding Tribocorrosion in Chloride Solution, Wear, 2017, 380, p 251–259.

H.Y. Ha, M.H. Jang, T.H. Lee, and J. Moon, Interpretation of the Relation Between Ferrite Fraction and Pitting Corrosion Resistance of Commercial 2205 Duplex Stainless Steel, Corros. Sci., 2014, 89, p 154–162.

A. Pinol-Juez, A. Iza-Mendia, and I. Gutierrez, δ/γ Interface Bondary Sliding as a Mechanism for Strain Accommodation During Hot Deformation in a Duplex Stainless Steel, Metall. Mater. Trans. A., 2000, 31(6), p 1671–1677.

J.S. Lee, K. Fushimi, T. Nakanishi, Y. Hasegawa, and Y.-S. Park, Corrosion Behaviour of Ferrite and Austenite Phases on Super Duplex Stainless Steel in a Modified Green-Death Solution, Corros. Sci., 2014, 89, p 111–117.

Z. Zhang, H. Jing, L. Xu, Y. Han, L. Zhao, and X. Lv, Effect of Post-Weld Heat Treatment on Microstructure Evolution and Pitting Corrosion Resistance of Electron Beam-Welded Duplex Stainless Steel, Corros. Sci., 2018, 141, p 30–45.

J. Rajaguru and N. Arunachalam, Investigation on Machining Induced Surface and Subsurface Modifications on the Stress Corrosion Crack Growth Behaviour of Super Duplex Stainless Steel, Corros. Sci., 2018, 141, p 230–242.

H.-Y. Ha, T.-H. Lee, C.-G. Lee, and H. Yoon, Understanding the Relation Between Pitting Corrosion Resistance and Phase Fraction of S32101 Duplex Stainless Steel, Corros. Sci., 2019, 149, p 226–235.

N. Lopez, M. Cid, and M. Puiggali, Influence of o-Phase on Mechanical Properties and Corrosion Resistance of Duplex Stainless Steels, Corros. Sci., 1999, 41(8), p 1615–1631.

S.-H. Jeon, H.-J. Kim, and Y.-S. Park, Effects of Inclusions on the Precipitation of Chi Phases and Intergranular Corrosion Resistance of Hyper Duplex Stainless Steel, Corros. Sci., 2014, 87, p 1–5.

L. Chiu, Y. Su, F. Chen, and H. Chang, Microstructure and Properties of Active Screen Plasma Nitrided Duplex Stainless Steel, Mater. Manuf. Processes., 2010, 25(5), p 316–323.

O.P. Calabokis, Y.N. de la Rosa, C.M. Lepienski, R.P. Cardoso, and P.C. Borges, Crevice and Pitting Corrosion of Low Temperature Plasma Nitrided UNS S32750 Super Duplex Stainless Steel, Surf. Coat. Tech., 2021, 413, p 127095.

Y. Zhang, Q. Hu, M. Dai, F. Huang, F.Y. Cheng, and J. Liu, Investigation of Micro-Electrochemical Activities of Oxide Inclusions and Microphases in Duplex Stainless Steel and the Implication on Pitting Corrosion, Mater. Corros., 2020, 71(6), p 876–886.

G. Tranchida, M. Clesi, F. Di Franco, F. Di Quarto, and M. Santamaria, Electronic Properties and Corrosion Resistance of Passive Films on Austenitic and Duplex Stainless steels, Electrochim. Acta., 2018, 273, p 412–423.

Y. Behnamian, A. Mostafaei, A. Kohandehghan, B. Zahiri, W. Zheng, D. Guzonas, M. Chmielus, W. Chen, and J.L. Luo, Corrosion Behavior of Alloy 316L Stainless Steel After Exposure to Supercritical Water at 500 C for 20,000 h, J. Supercrit. Fluid., 2017, 127, p 191–199.

C. Dai, T. Zhao, C. Du, Z. Liu, and D. Zhang, Effect of Molybdenum Content on the Microstructure and Corrosion Behavior of FeCoCrNiMox High-Entropy Alloys, J. Mater. Sci. Technol., 2020, 46, p 64–73.

D. Shintani, T. Ishida, H. Izumi, T. Fukutsuka, Y. Matsuo, and Y. Sugie, XPS Studies on Passive Film Formed on Stainless Steel in a High-Temperature and High-Pressure Methanol Solution Containing Chloride Ions, Corros. Sci., 2008, 50(10), p 2840–2845.

V. Maurice, W. Yang, and P. Marcus, XPS and STM Study of Passive Films Formed on Fe-22Cr (110) Single-Crystal Surfaces, J. Electrochem. Soc., 1996, 143(4), p 1182.

Z. Wang, Z.-Q. Zhou, L. Zhang, J.-Y. Hu, Z.-R. Zhang, and M.-X. Lu, Effect of pH on the Electrochemical Behaviour and Passive Film Composition of 316L Stainless Steel, Acta. Metall. Sin-Engl., 2019, 32(5), p 585–598.

J. Hesketh, E. Dickinson, M.L. Martin, G. Hinds, and A. Turnbull, Influence of H2S on the Pitting Corrosion of 316L Stainless Steel in Oilfield Brine, Corros. Sci., 2021, 182, p 109265.

Z. Cui, L. Wang, H. Ni, W. Hao, C. Man, S. Chen, X. Wang, Z. Liu, and X. Li, Influence of Temperature on the Electrochemical and Passivation Behavior of 2507 Super Duplex Stainless Steel in Simulated Desulfurized Flue Gas Condensates, Corros. Sci., 2017, 118, p 31–48.

Z. Cui, S. Chen, Y. Dou, S. Han, L. Wang, C. Man, X. Wang, S. Chen, Y.F. Cheng, and X. Li, Passivation Behavior and Surface Chemistry of 2507 Super Duplex Stainless Steel in Artificial Seawater: Influence of Dissolved Oxygen and pH, Corros. Sci., 2019, 150, p 218–234.

Z. Jin, H. Ge, W. Lin, Y. Zong, S. Liu, and J. Shi, Corrosion Behaviour of 316L Stainless Steel and Anti-Corrosion Materials in a High Acidified Chloride Solution, Appl. Surf. Sci., 2014, 322, p 47–56.

Z. Wang, L. Zhang, X. Tang, Z. Zhang, and M. Lu, The Surface Characterization and Passive Behavior Of Type 316L Stainless Steel in H2S-Containing Conditions, Appl. Surf. Sci., 2017, 423, p 457–464.

J.-S. Lee, Y. Kitagawa, T. Nakanishi, Y. Hasegawa, and K. Fushimi, Passivation Behavior of Type-316L Stainless Steel in the Presence of Hydrogen Sulfide Ions Generated from a Local Anion Generating System, Electrochim. Acta., 2016, 220, p 304–311.

L. Jinlong, L. Tongxiang, and W. Chen, Surface Enriched Molybdenum Enhancing the Corrosion Resistance of 316L Stainless Steel, Mater. Lett., 2016, 171, p 38–41.

Y.-S. Lu, C.-W. Lu, Y.-T. Lin, H.-W. Yen, and Y.-L. Lee, Corrosion Behavior and Passive Film Characterization of Fe50Mn30Co10Cr10 Dual-Phase High-Entropy Alloy in Sulfuric Acid Solution, J. Electrochem. Soc., 2020, 167(8), p 081506.

Z. Wang, L. Zhang, Z. Zhang, and M. Lu, Combined Effect of pH and H2S on the Structure of Passive Film Formed on Type 316L Stainless Steel, Appl. Surf. Sci., 2018, 458, p 686–699.

Z. Wang, Z. Feng, X.-H. Fan, and L. Zhang, Pseudo-Passivation Mechanism of CoCrFeNiMo0.01 High-Entropy Alloy in H2S-Containing Acid Solutions, Corros. Sci., 2021, 179, p 109146.

G. Šekularac and I. Milošev, Corrosion of Aluminium Alloy AlSi7Mg0.3 in Artificial Sea Water with Added Sodium Sulphide, Corros. Sci., 2018, 144, p 54–73.

C.-J. Park and H.-S. Kwon, Effects of aging at 475 C on Corrosion Properties of Tungsten-Containing Duplex Stainless Steels, Corros. Sci., 2002, 44(12), p 2817–2830.

R. Silva, G. Vacchi, C. Kugelmeier, I. Santos, A. Mendes Filho, D. Magalhães, C. Afonso, V. Sordi, and C. Rovere, New Insights into the Hardening and Pitting Corrosion Mechanisms of Thermally Aged Duplex Stainless steel at 475° C: A Comparative Study Between 2205 and 2101 Steels, J. Mater. Sci. Technol., 2022, 98, p 123–135.

Y. Shi, C. Peng, Y. Feng, R. Wang, and N. Wang, Microstructure and Electrochemical Corrosion Behavior of Extruded Mg–Al–Pb–La alloy as Anode for Seawater-Activated Battery, Mater. Des., 2017, 124, p 24–33.

H. Yang, L. Wu, B. Jiang, W. Liu, J. Song, G. Huang, D. Zhang, and F. Pan, Clarifying the Roles of Grain Boundary and Grain Orientation on the Corrosion and Discharge Processes of α-Mg Based Mg-Li Alloys for Primary Mg-air Batteries, J. Mater. Sci. Technol., 2021, 62, p 128–138.

G. Frankel, Pitting Corrosion of Metals: A Review of the Critical Factors, J. Electrochem. Soc., 1998, 145(6), p 2186.

R. Silva, C. Kugelmeier, G. Vacchi, C.M. Junior, I. Dainezi, C. Afonso, A. Mendes Filho, and C. Rovere, A Comprehensive Study of the Pitting Corrosion Mechanism of Lean Duplex Stainless Steel Grade 2404 Aged at 475 °C, Corros. Sci., 2021, 191, p 109738.

A. Davoodi, M. Pakshir, M. Babaiee, and G.R. Ebrahimi, A Comparative H2S Corrosion Study of 304L and 316L Stainless Steels in Acidic Media, Corros. Sci., 2011, 53(1), p 399–408.

G. Hinds, L. Wickström, K. Mingard, and A. Turnbull, Impact of Surface Condition on Sulphide Stress Corrosion Cracking of 316L Stainless Steel, Corros. Sci., 2013, 71, p 43–52.

Y. Zhou and D.L. Engelberg, Fast Testing of Ambient Temperature Pitting Corrosion in Type 2205 Duplex Stainless Steel by Bipolar Electrochemistry Experiments, Electrochem. Commun., 2020, 117, p 106779.

Z. Wang, G.-H. Zhang, X.-H. Fan, J. Jin, L. Zhang, and Y.-X. Du, Corrosion Behavior and Surface Characterization of an Equiatomic CoCrFeMoNi High-Entropy Alloy Under Various pH Conditions, J. Alloys Compd., 2022, 900, p 163432.

Y. Lu, J. Dong and W. Ke, Effects of Cl− Ions on the Corrosion Behaviour of Low Alloy Steel in Deaerated Bicarbonate Solutions, J. Mater. Sci. Technol., 2016, 32(4), p 341–348.

F. Di Quarto and M. Santamaria, Semiconductor Electrochemistry Approach to Passivity and Passivity Breakdown of Metals and Metallic Alloys, Corros. Eng. Sci. Techn., 2004, 39(1), p 71–81.

H. Engell, Stability and Breakdown Phenomena of Passivating Films, Electrochim. Acta., 1977, 22(9), p 987–993.

M.S. Islam, K. Otani, and M. Sakairi, Effects of Metal Cations on Mild Steel Corrosion in 10 mM Cl− Aqueous Solution, Corros. Sci., 2018, 131, p 17–27.

D.H. Xia, Z. Qin, S. Song, D. Macdonald, and J.L. Luo, Combating Marine Corrosion on Engineered Oxide Surface by Repelling, Blocking and Capturing Cl−: A Mini Review, Corros. Sci., 2021, 2, p 1–7.

Z. Feng, X. Cheng, C. Dong, L. Xu, and X. Li, Passivity of 316L Stainless Steel in Borate Buffer Solution Studied by Mott-Schottky Analysis, Atomic Absorption Spectrometry and x-ray Photoelectron Spectroscopy, Corros. Sci., 2010, 52(11), p 3646–3653.

P. Marcus, Surface Science Approach of Corrosion Phenomena, Electrochim. Acta., 1998, 43(1–2), p 109–118.

D. Shoesmith, P. Taylor, M. Bailey, and B. Ikeda, Electrochemical Behaviour of Iron in Alkaline Sulphide Solutions, Electrochim. Acta., 1978, 23(9), p 903–916.

H. Ma, X. Cheng, G. Li, S. Chen, Z. Quan, S. Zhao, and L. Niu, The Influence of Hydrogen Sulfide on Corrosion of Iron Under Different Conditions, Corros. Sci., 2000, 42(10), p 1669–1683.

H. Ma, X. Cheng, S. Chen, C. Wang, J. Zhang, and H. Yang, An ac Impedance Study of the Anodic Dissolution of Iron in Sulfuric Acid Solutions Containing Hydrogen Sulfide, J. Electroanal. Chem., 1998, 451(1–2), p 11–17.

X. Cheng, H. Ma, S. Chen, L. Niu, S. Lei, R. Yu, and Z. Yao, Electrochemical Behaviour of Chromium in Acid Solutions with H2S, Corros. Sci., 1999, 41(4), p 773–788.

X. Cheng, H. Ma, S. Chen, X. Chen, and Z. Yao, Corrosion of Nickel in acid Solutions with Hydrogen Sulphide, Corros. Sci., 2000, 42(2), p 299–311.

H. Luo, C. Dong, K. Xiao, and X. Li, The Passive Behaviour of Ferritic Stainless Steel Containing Alloyed Tin IN Acidic Media, RSC. Adv., 2016, 6(12), p 9940–9949.

R. Newman, W. Wong, H. Ezuber, and A. Garner, Pitting of Stainless Steels by Thiosulfate Ions, Corros., 1989, 45(4), p 282–287.

W. Li, T. Guo, L. Xu, L. Chen, B. Jiang, X. Wang, H. Wu, and L. Qiao, Promotion of Pitting Corrosion at Hydrogen-Enriched α/γ Phase Boundaries in Austenitic Stainless Steel Weld Joints, Acta. Mater., 2022, 227, p 117728.

I. Betova, M. Bojinov, O. Hyökyvirta, and T. Saario, Effect of Sulphide on the Corrosion Behaviour of AISI 316L Stainless Steel and its Constituent Elements in Simulated Kraft Digester Conditions, Corros. Sci., 2010, 52(4), p 1499–1507.

K.R. Chasse and P.M. Singh, Corrosion Study of Super Ferritic Stainless Steel UNS S44660 (26Cr-3Ni-3Mo) and Several Other Stainless Steel Grades (UNS S31603, S32101, and S32205) in Caustic Solution Containing Sodium Sulfide, Metall. Mater. Trans. A., 2013, 44(11), p 5039–5053.

Acknowledgements

This work was supported by National Natural Science Foundation of China (52101067) and Fundamental Research Funds for the Central Universities (FRF-TP-20-098A1).

Author information

Authors and Affiliations

Contributions

GZ: is the principal investigator of the project. He conducted the electrochemical and surface analysis. He planned the scope of work, designed the research plan and finished the manuscript. JJ: conducted the electrochemical. YR: conducted the latest literature research. ZW: worked with the first author to analyze the results and reviewed this article. LZ: worked with the first author to analyze the results.

Corresponding author

Ethics declarations

Conflict of interest

The authors report no declarations of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, G., Jin, J., Wang, Z. et al. Corrosion Behavior of 2507 Super Duplex Stainless Steel in H2S-Free and H2S-Containing Acidic Environments. J. of Materi Eng and Perform 32, 1185–1195 (2023). https://doi.org/10.1007/s11665-022-07163-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07163-y