Abstract

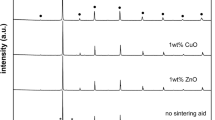

The effect of BaO insertion on the ionic conductivity of 8 mol.% yttria-stabilized zirconia (8YSZ) was investigated using electrochemical impedance spectroscopy with a frequency response analyzer in the frequency range of 100 mHz-13 MHz and the temperature range of 300-800 °C. X-ray diffraction (XRD) and scanning electron microscopy (SEM) analysis indicated that while the BaO could be dissolved in the zirconia at 1 wt.%, it did not dissolve in the zirconia above 1 wt.% (5, 10, and 15 wt.%). Furthermore, it led to forming of BaZrO3 secondary phases at the 8YSZ's grain boundaries when the BaO was doped to 8YSZ at the amounts of more than 1 wt.%. This BaZrO3 secondary phase reduced the grain size of 8YSZ from 4.48 to 0.71 μm after sintering at 1400 °C for 50 h. Rietveld analysis showed that the lattice parameter of ZrO2 decreased from 5.138 to 5.130 Å and that of BaZrO3 decreased from 4.189 to 4.181 Å at a content of 15 wt.% BaO. The impedance spectroscopy results showed that zirconia's grain interior conductivity at 400 °C was increased from 1.17 × 10-4 to 1.56 × 10-4 S/cm by 5 wt.% BaO addition, and the grain boundary conductivity at 400 °C was also enhanced from 7.21 × 10-6 to 4.90 × 10-5 S/cm by 1 wt.% BaO addition. Additionally, the grain interior activation energy of 8YSZ was reduced from 1.15 to 0.97 eV by 5 wt.% BaO addition and grain boundary activation energy from 1.50 to 1.17 eV by 1 wt.% BaO addition. The most significant outcome of this study is that the grain interior and grain boundary conductivity of 8YSZ was increased by 33% and 47%, respectively, at low temperatures (400 °C) with the addition of BaO. In conclusion, the present study displayed that BaO addition to 8YSZ improved the ionic conductivity and might be used as a solid electrolyte material in SOFCs.

Similar content being viewed by others

References

B. Aktas, Influence of Borosilicate Addition on Mechanical Properties and Sinterability of 8YSZ, Acta Phys. Pol. A, 2016, 129(4), p 677–679.

B. Aktaş and S. Tekeli, Ionic conductivity of MgAl2O4-doped 8YSZ ceramics, Arab. J. Geosci., 2019, 12, p 478.

E. Ivers-Tiffee, A. Weber, and D. Herbstritt, Materials and technologies for SOFC-components, J. Eur. Ceram. Soc., 2001, 21(10–11), p 1805–1811.

N.P. Bansal and D. Zhu, Thermal conductivity of zirconia–alumina composites, Ceram. Int., 2005, 31(7), p 911–916.

B. Aktaş, S. Tekeli, and S. Salman, Inuence on Static Grain Growth and Sinterability of BaO Addition into 8YSZ, Acta Phys. Pol. A, 2014, 125(2), p 652–655.

S. Kumar, S. Bhunia, and A.K. Ojha, Effect of calcination temperature on phase transformation, structural and optical properties of sol–gel derived ZrO2 nanostructures, Phys. E. Low Dimens. Syst. Nanostruct., 2015, 66, p 74–80.

K. Smits, L. Grigorjeva, D. Millers, A. Sarakovskis, A. Opalinska, J.D. Fidelus, and W. Lojkowski, Europium doped zirconia luminescence, Opt. Mater., 2010, 32(8), p 827–831.

A.J. Moulson and J.M. Herbert, Electroceramics Materials, Properties, Applications, Wiley, New York, 2003. https://doi.org/10.1002/0470867965

R.C. Buchanan, Ceramics Materials for Electronics, Marcel Dekker Inc, New York, 1991. https://doi.org/10.1002/adma.19920040427

B. Aktas, S. Tekeli, and S. Salman, Improvements in Microstructural and Mechanical Properties of ZrO2 Ceramics After Addition of BaO, Ceram. Int., 2016, 42(3), p 3849–3854.

B. Aktas, S. Tekeli, and S. Salman, Crystallization and Grain Growth Behavior of La2O3-doped Yttria-stabilized Zirconia, Adv Mater Lett., 2014, 5(5), p 260–264.

J. Wu, Defect Chemistry and Proton Conductivity in Ba-based Perovskites Ph.D. dissertation, California Institute of Technology, 2005.

M. Khalid Hossain, T. Yamamoto, and K. Hashizume, Effect of sintering conditions on structural and morphological properties of Y- and Co-doped BaZrO3 proton conductors, Ceram. Int., 2021, 47(19), p 27177–27187.

H. Ji, B.K. Kim, J.W. Son, K.J. Yoon, and J.H. Lee, Influence of Sintering Activators on Electrical Property of BaZr085Y015O3-δ Proton-Conducting Electrolyte, J. Power Sources, 2021, 507, p 230296.

M.K. Hossain, R. Chanda, A. El-Denglawey, T. Emrose, M.T. Rahman, M.C. Biswas, and K. Hashizume, Recent Progress in Barium Zirconate Proton Conductors for Electrochemical Hydrogen Device Applications: A Review, Ceram. Int., 2021, 47(17), p 23725–23748.

H. Bao, R. Chen, X. Wang, Y. Yang, T. Lin, X. Wang, X. Ou, Y. Tian, and Y. Ling, Characterization of One-Step Co-Fired BaZr0.8Y0.2O3-δ-La2Ce2O7 Composite Electrolyte for Low-Temperature Solid Oxide Fuel Cells, J. Eur. Ceram., 2021, 41(11), p 5531–5540.

P. Khirade, A.V. Raut, R.C. Alange, W.S. Barde, and A.R. Chavan, Structural, Electrical and Dielectric Investigations of cerium Doped Barium Zirconate (BaZrO3) Nano-Ceramics Produced via Green Synthesis: Probable Candidate for Solid Oxide Fuel Cells and Microwave Applications, Phys. B, 2021, 613, 412948.

D.A. Monteiro, M.M. Costa, and R.R.F. Bento, Structural Refinement, Morphological and Electrical Properties of BaZrO3:Bi(Zn1/2Ti1/2)O3 Lead-Free Ceramics, J. Alloys Compd., 2021, 868, 159221.

C.Y.R. Vera, H. Ding, D. Peterson, W.T. Gibbons, M. Zhou, and D. Ding, A Mini-Review on Proton Conduction of BaZrO3-Based Perovskite Electrolytes, J. Phys. Energy, 2021, 3(3), p 032019.

A. Uthayakumar, M. Kavithanjali, K. Sandhya, N. Ponpandian, and K. SureshBabu, The Rare Earth Dopant (La, Gd, Sm & Y) modulated Grain Boundary Energy Barrier Suppression in BaZrO3-BaCeO3 Solid Solution, J. Alloys Compd., 2021, 864, p 158098.

J.A. Wrubel, J. Gifford, Z. Ma, H. Ding, D. Ding, and T. Zhu, Modeling the Performance and Faradaic Efficiency of Solid Oxide Electrolysis Cells Using Doped Barium Zirconate Perovskite Electrolytes, Int. J. Hydrog. Energy, 2021, 46(21), p 11511–11522.

K. Ueno, N. Hatada, D. Han, K. Toyoura, and T. Uda, Reexamination of the Phase Diagram of the BaO-ZrO2-Y2O3 System: Investigation of the Presence of Separate Region in Y-doped BaZrO3 Solid Solution and the Dissolution of Zr in Ba3Y4O9, J. Solid State Electrochem., 2020, 24, p 1523–1538.

F.M. Draber, C. Ader, J.P. Arnold, S. Eisele, S. Grieshammer, S. Yamaguchi, and M. Martin, Nanoscale Percolation in Doped BaZrO3 for High Proton Mobility, Nat. Mater., 2020, 19, p 338–346.

S. Kasamatsu, O. Sugino, T. Ogawa, and A. Kuwabara, Dopant Arrangements in Y-Doped BaZrO3 Under Processing Conditions and their Impact on Proton Conduction: a Large-Scale First-Principles Thermodynamics Study, J. Mater. Chem. A, 2020, 8(25), p 2050–7488.

S.A. Rasaki, C. Liu, C. Lao, and Z. Chen, A Review of Current Performance of Rare Earth Metal-Doped Barium Zirconate Perovskite: The Promising Electrode and Electrolyte Material for the Protonic Ceramic Fuel Cells, Prog. Solid. State Ch., 2021, 63, 100325.

S. Tao and J.T.S. Irvine, Conductivity Studies of Dense Yttrium-Doped BaZrO3 Sintered at 1325 °C, J. Solid State Chem., 2007, 180, p 3493–3503.

J.S. Park, J.H. Lee, H.W. Lee, and B.K. Kim, Low Temperature Sintering of BaZrO3-Based Proton Conductors for Intermediate Temperature Solid Oxide Fuel Cells, Solid State Ionics, 2010, 181, p 163–167.

P. Babilo, T. Uda, and S.M. Haile, Processing of Yttrium-Doped Barium Zirconate for High Proton Conductivity, J. Mater. Res., 2007, 22(05), p 1322–1330.

A. Yadav, R. Pyare, T. Maiyalagan, and P. Singh, Synthesis, Characterization, and Ionic Conductivity Studies of Simultaneously Substituted K- and Ga-Doped BaZrO3, ACS Omega, 2021, 6, p 30327–30334.

S. Tekeli, B. Aktaş, and M. Küçüktüvek, Microstructural and Mechanical Properties of Er2O3-ZrO2 Ceramics with Different Er2O3 Contents, High Temp. Mater. Proc., 2012, 31(6), p 701–706.

B. Aktas, S. Tekeli, and S. Salman, Synthesis and Properties of La2O3-Doped 8 mol% Yttria-Stabilized Cubic Zirconia, J. Mater. Eng. Perform., 2014, 23(1), p 294–301.

B. Aktas and S. Tekeli, Influence of Co3O4 Addition on the Ionic Conductivity and Microstructural Properties of Yttria-Stabilized Zirconia (8YSZ), Int. J. Mater. Res., 2014, 105(6), p 577–583.

B. Aktas, Microstructure, Mechanical and Electrical Properties of CuO Doped 8YSZ, High Temp. Mater. Proc., 2013, 32(6), p 551–556.

J. Brezinska-Miecznik, K. Haberko, and M.M. Bucko, Barium Zirconate Ceramic Powder Synthesis by Thecoprecipitation–Calcination Technique, Mater. Lett., 2002, 56, p 273–278.

D. Schultze, Differentialthermoanalyse (Differential Thermal Analysis), VEB Deutscher Verlag der Wissenschaften, Berlin, 1971 https://doi.org/10.1002/anie.197001782

M.K. Hossain, T. Yamamoto, and K. Hashizume, Effect of Sintering Conditions on Structural and Morphological Properties of Y- and Co-Doped BaZrO3 Proton Conductors, Ceram. Int., 2021, 47(19), p 27177–27187.

M. Miyayama, H. Yanagida, and A. Asada, Effects of Al2O3 Additions on Resistivity and Microstructure of Yttria-Stabilized Zirconia, Am. Ceram. Soc. Bull., 1985, 64(4), p 660–664.

J.E. Bauerle, Study of Solid Electrolyte Polarization by a Complex Admittance Method, J. Phys. Chem. Solids, 1969, 30(12), p 2657–2670.

Y. Li, M.S. Liu, J.H. Gong, Y.F. Chen, Z.L. Tang, and Z.T. Zhang, Grain-Boundary Effect in Zirconia Stabilized with Yttria and Calcia by Electrical Measurements, Mater. Sci. Eng. B, 2003, 103(2), p 108–114.

M. Gödickemeier, B. Michel, A. Orliukas, P. Bohac, K. Sasaki, L. Gauckler, H. Heinrich, P. Schwander, G. Kostorz, H. Hofmann, and O. Frei, Effect of Intergranular Glass Films on the Electrical Conductivity of 3Y-TZP, J. Mater. Res., 1994, 9, p 1228–1240.

M. Aoki, Y.M. Chiang, I. Kosacki, L.J.R. Lee, H. Tuller, and Y. Liu, Solute Segregation and Grain-Boundary Impedance in High-Purity Stabilized Zirconia, J. Am. Ceram. Soc., 1996, 79(5), p 1169–1180.

M.J. Verkerk, B.J. Middelhuis, and A.J. Burggraaf, Effect of Grain Boundaries on the Conductivity of High-Purity ZrO2-Y2O3 Ceramics, Solid State Ion., 1982, 6, p 159–170.

B. Aktas, S. Tekeli, and M. Kucuktuvek, Electrical Conductivity of Er2O3-Doped c-ZrO2 Ceramics, J. Mater. Eng. Perform., 2014, 23(1), p 349–355.

X. Guo and J. Maier, Grain Boundary Blocking Effect in Zirconia: A Schottky Barrier Analysis, J. Electrochem. Soc., 2001, 148(3), p E121–E126.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aktas, B., Tekeli, S. & Salman, S. Role of BaZrO3 Phase on Microstructure and Ionic Conductivity of 8YSZ. J. of Materi Eng and Perform 31, 8981–8988 (2022). https://doi.org/10.1007/s11665-022-06916-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06916-z