Abstract

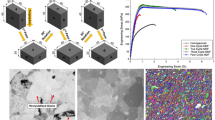

Al-1.9Mn-5Fe (wt.%) alloy was prepared by adding 5 wt.% Fe to the eutectic Al-Mn alloy. This alloy undergone controlled solidification under four different growth velocities (V) in Bridgman-type furnace. Eutectic spacings (λ), microhardness (HV), ultimate tensile strength (σU) and electrical resistivity (ρ) of these alloys were determined. While the HV and σU increased with increasing V values or decreasing λ, the elongation (δ) values decreased. In addition, relationships between these parameters were investigated using linear regression analysis. Microstructure photographs of directionally solidified samples were taken by optical microscope and scanning electron microscope (SEM). The eutectic spacings were measured from these photographs. The relationships among growth velocity (V), eutectic spacing (λ), microhardness (HV), ultimate tensile strength (σU) and electrical resistivity (ρ) were measured by suitable method and tests. The ρ measurements were carried out depending on V and temperature (T). While temperature coefficient of resistivity (αTCR) was calculated from the ρ–T curve, the values of thermal conductivity (K) predicted by Wiedemann–Franz (W–F) and Smith–Palmer (S–P) equations. It was found that the microstructure, microhardness, tensile strength and electrical resistivity were affected by both eutectic spacing and the growth velocity.

Similar content being viewed by others

Change history

25 January 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11665-020-05384-7

References

E.J. Lavernia and N.J. Grant, Aluminium-Lithium Alloys, J. Mater. Sci., 1987, 22, p 1521–1529

M. Gündüz and E. Çadırlı, Directional Solidification of Aluminium–Copper Alloys, Mater. Sci. Eng. A, 2002, 327, p 167–185

H. Kaya, U. Böyük, E. Çadırlı, and N. Maraşlı, Influence of Growth Rate on Microstructure, Microhardness and Electrical Resistivity of Directionally Solidified Al-7 wt.% Ni Hypo-Eutectic Alloy, Met. Mater. Int., 2013, 19, p 39–44

E. Çadırlı, Effect of Cooling Rate and Composition on Mechanical Properties of the Directionally Solidified Al-rich Al-Cu Alloys, Met. Mater. Int., 2013, 19, p 411–422

E. Çadırlı, E. Nergiz, H. Kaya, U. Büyük, M. Şahin, and M. Gündüz, Effect of Growth Velocity on Microstructure and Mechanical Properties of Directionally Solidified 7075 Alloy, Int. J. Cast Met. Res., 2020, 33, p 11–23

Q. Zhao, Z. Qian, X. Cui, Y. Wu, and X. Liu, Optimizing Microstructures of Dilute Al-Fe-Si Alloys Designed with Enhanced Electrical Conductivity and Tensile Strength, J. Alloys Compd., 2015, 650, p 768–776

D. Pavlyuchkov, S. Balanetskyy, W. Kowalski, M. Surowiec, and B. Grushko, Stable Decagonal Quasicrystals in the Al-Fe-Cr and Al-Fe-Mn Alloy Systems, J. Alloys Compd., 2009, 477, p L41–L44

O. Engler, G. Laptyeva, and N. Wang, Impact of Homogenization on Microchemistry and Recrystallization of the Al-Fe-Mn Alloy AA 8006, Mater. Charact., 2013, 79, p 60–75

S. Balanetskyy, D. Pavlyuchkov, T. Velikanova, and B. Grushko, The Al-Rich Region of the Al-Fe-Mn alloy system, J. Alloys Compd., 2015, 619, p 211–220

R. Oliveira, R. Kakitani, L.R. Ramos, D.L. Gonçalves, A. Garcia, and N. Cheung, The Roles of Mn and Ni Additions to Fe Contaminated Al in Neutralizing Fe and Stabilizing the Cellular α-Al Microstructure, J. Sustain. Metall., 2019, 5, p 561–580

W.W. Zhang, B. Lin, D.T. Zhang, and Y.Y. Li, Microstructures and Mechanical Properties of Squeeze Cast Al-5.0Cu-0.6Mn Alloys with Different Fe Content, Mater. Design., 2013, 52, p 225–233

I.J. Polmear, Light Alloys: Metallurgy of the Light Metals, Wiley, Hoboken, 1995

W.T. Denholm, J.D. Esdaile, N.G. Siviour, and B.W. Wilson, The Nature of the FeAl3 Liquid (FeMn)Al6 Reaction in the Al-Fe-Mn System, Metall. Mater. Trans. A, 1987, 18, p 393–397

S.G. Shabestari, The Effect Fe and Mn on Formation of Intermetallic Compounds in Al-Si Alloys, Mater. Sci. Eng. A, 2004, 383, p 289–298

J.Y. Hwang, H.W. Doty, and M.J. Kaufman, The Effects of Mn Additions on the Microstructure and Mechanical Properties of Al-Si-Cu Casting Alloys, Mater. Sci. Eng. A., 2008, 488, p 496–504

C.M. Dinnis, J.A. Taylor, and A.K. Dahle, Interactions Between Iron, Manganese, and the Al-Si Eutectic in Hypoeutectic Al-Si Alloys, Metall. Mater. Trans. A, 2006, 37, p 3283–3291

L.F. Mondolfo, Manganese in Aluminum Alloys, The Manganese Centre, Paris, 1978

R. Mehrabian, M. Kaene, and M.C. Flemings, Interdendritic Fluid Flow and Macrosegregation; Influence of Gravity, Met. Trans, 1970, 1, p 1209–1220

D.G. Eskin, J. Zuidema, V.I. Savran, and L. Katgerman, Structure Formation and Macrosegregation Under Different Process Conditions During DC Casting, Mater. Sci. Eng. A, 2004, 384, p 232–244

A.P. Boeira, I.L. Ferreira, and A. Garcia, Alloy Composition and Metal/Mold Heat Transfer Efficiency Affecting Inverse Segregation and Porosity of As-Cast Al–Cu Alloys, Mater. Des., 2009, 30, p 2090–2098

C.M. Allen, S. Kumar, L. Carrol, K.A.Q. O’Reilly, and H. Cama, Electron Beam Surface Melting of Model 1200 Al alloys, Mater. Sci. Eng. A, 2001, 304–306, p 604–607

M. Karlik, J. Siegl, M. Slamova, and Y. Birol, Study of the Damage of AA 8006 Twin-Roll Cast Thin Sheets During Forming of Heat Exchanger Fins, Mater. Sci. Forum, 2000, 331–337, p 619–624

B. Dutta and M. Rettenmayr, Effect of Cooling Rate on the Solidification Behaviour of Al-Fe-Si Alloys, Mater. Sci. Eng. A, 2000, 283, p 218–224

Y.H. Zhang, Y.C. Liu, Y.J. Han, C. Wei, and Z.M. Gao, The Role of Cooling Rate in the Microstructure of Al-Fe-Si Alloy with High Fe and Si Contents, J. Alloys Compd., 2009, 473, p 442–445

P.R. Goulart, J.E. Spinelli, N. Cheung, and A. Garcia, The Effects of Cell Spacing and Distribution of Intermetallic Fibers on the Mechanical Properties of Hypoeutectic Al-Fe Alloys, Mater. Chem. Phys., 2010, 119, p 272–278

I.L. Ferreira, J.A. de Castro, and A. Garcia, Determination of Heat Capacity of Pure Metals, Compounds and Alloys by Analytical and Numerical Methods, Thermochim. Acta, 2019, 682, p 178418

J.R. Davis, Ed., ASM Specialty Handbook: Aluminum and Aluminum Alloys, ASM International, Materials Park, 1993

E. Çadırlı, U. Boyuk, S. Engin, H. Kaya, N. Maraşlı, and A. Ülgen, Experimental Investigation of the Effect of Solidification Processing Parameters on the Rod Spacings in the Sn-1.2 wt.% Cu Alloy, J. Alloys Compd., 2009, 486, p 199–206

E. Çadırlı, A. Aker, Y. Kaygısız, and M. Şahin, Influences of Growth Velocity and Fe Content on Microstructure, Microhardness and Tensile Properties of Directionally Solidified Al-1.9Mn-xFe Ternary Alloys, Mater. Res., 2017, 20, p 801–813

C. Kittel, Introduction to Solid State Physics, 6th ed., Wiley, New York, 1965

D.R. Poirier and G.H. Geiger, Transport Phenomena in Materials Processing, Metals and Materials Society, Pittsburgh, Mineral, 1994

E. Çadırlı, M. Şahin, R. Kayalı, M. Arı, and S. Durmuş, Dependence of Electrical and Thermal Conductivity on Temperature in Directionally Solidified Sn-3.5 wt.% Ag Eutectic Alloy, J. Mater. Sci. Mater. Electron., 2011, 22, p 1709–1714

M. Gündüz, H. Kaya, E. Çadırlı, and A. Özmen, Interflake Spacings and Undercoolings in Al-Si Irregular Eutectic Alloy, Mater. Sci. Eng. A, 2004, 369, p 215–229

S. Steinbach and L. Ratke, The Influence of Fluid Flow on the Microstructure of Directionally Solidified AlSi-Base Alloys, Metall. Mater. Trans. A, 2007, 38, p 1388–1394

A. Aker, S. Engin, İ. Yılmazer, and H. Kaya, Influence of the Growth Rate on Physical Properties in the Aluminum-Antimony Eutectic Alloy, Int. J. Mater. Eng. Technol., 2013, 9, p 59–76

J. Fan, X. Li, Y. Su, J. Guo, and H. Fu, The Microstructure Parameters and Microhardness of Directionally Solidified Ti-43Al-3Si Alloy, J. Alloys Compd., 2010, 506, p 593–599

E. Çadırlı, İ. Yılmazer, M. Sahin, and H. Kaya, Investigation of the Some Physical Properties of the Directionally Solidified Al-Cu-Co Ternary Eutectic Alloy, Trans. Indian Inst. Met., 2015, 68, p 817–827

J.T. Guo, C.M. Xu, X.H. Du, and H. Fu, The Effect of Solidification Rate on Microstructure and Mechanical Properties of an Eutectic NiAl-Cr(Mo)-Hf Alloy, Mater. Lett., 2004, 58, p 3233–3236

S. Engin, U. Büyük, and N. Maraşlı, The Effects of Microstructure and Growth Rate on Microhardness, Tensile Strength, and Electrical Resistivity for Directionally Solidified Al-Ni-Fe Alloys, J. Alloy. Compd., 2016, 660, p 21–23

J. Lapin and J. Marecek, Effect of Growth Rate on Microstructure and Mechanical Properties of Directionally Solidified Multiphase Intermetallic Ni-Al-Cr-Ta-Mo-Zr Alloy, Intermetallics, 2006, 14, p 1339–1344

J. Lapin, L. Ondrus, and M. Nazmy, Directional Solidification of Intermetallic Ti-46Al-2W-0.5Si Alloy in Alumina Moulds, Intermetallics, 2002, 10, p 1019–1031

J. Fan, X. Li, Y. Su, J. Guo, and H. Fu, Dependency of Microhardness on Solidification Processing Parameters and Microstructure Characteristics in the Directionally Solidified Ti-46Al-0.5W-0.5Si Alloy, J. Alloy Compd., 2010, 504, p 60–64

S. Khan, A. Ourdjini, Q.S. Hamed, M.A.A. Najafabadi, and R. Elliott, Hardness and Mechanical Property Relationships in Directionally Solidified Aluminium-Silicon Eutectic Alloys with Different Silicon Morphologies, J. Mater. Sci., 1993, 28, p 5957–5962

U. Böyük, N. Maraşlı, E. Çadırlı, H. Kaya, and K. Keşlioğlu, Variations of Microhardness with Solidification Parameters and Electrical Resistivity with Temperature for Al-Cu-Ag Eutectic Alloy, Curr. App. Phys., 2012, 12, p 7–10

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, and D.I. Chen, Effect of Solidification Rate and Loading Mode on Deformation Behavior of Cast Al-Si-Cu-Mg Alloy with Additions of Transition Metals, Mater. Sci. Eng. A, 2015, 636, p 361–372

S.G. Shabestari and F. Shahri, Influence of Modification, Solidification Conditions and Heat Treatment on the Microstructure and Mechanical Properties of A356 Aluminum Alloy, J. Mater. Sci., 2004, 39, p 2023–2032

D.D. Pollock, Electrical Conduction in Solids: An Introduction, ASM, Metals Park, 1985

Acknowledgments

This work was supported by the ERU, Scientific Research Project Unit (FBA-2015-5631). The authors are grateful for the supports to ERU Scientific Research Project Unit.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: In the headings for subsections 2.2, 2.3, 3.2, 3.3, 3.4 and 3.5, the symbols λ, ρ, σ and σU should have been used (just as used in the Abstract) for eutectic spacing, electrical resistivity, tensile strength, and ultimate tensile strength, respectively.

Rights and permissions

About this article

Cite this article

Yılmazer, İ., Çadırlı, E., Kaya, H. et al. Physical Properties of Directionally Solidified Al-1.9Mn-5Fe Alloy. J. of Materi Eng and Perform 30, 1603–1610 (2021). https://doi.org/10.1007/s11665-020-05253-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05253-3