Abstract

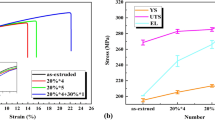

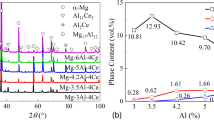

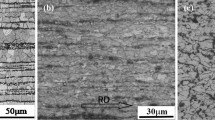

A low-cost and high-strength Mg-Al-Ca-Zn-Mn-Ce-based alloy sheet has been developed and fabricated by single-pass large-strain rolling process. Effects of rolling temperatures on the microstructure and mechanical properties of the Mg sheets have been investigated. The results show that the grain sizes of the Mg sheets are remarkably refined to be ~ 1.5 and ~ 0.8 µm after rolling at 350 and 250 °C (denoted as X-350 and X-250), respectively. The fine nano-precipitates are found to distribute both within the grain interiors and along the grain boundaries. co-segregations of Ca and Zn atoms also readily occur in present Mg sample, and the solute concentration increases with the decrease in rolling temperature. Nano-precipitates and solute segregations can effectively impede the grain growth and contribute to the grain refinement in as-rolled Mg samples. Optimal mechanical properties have been obtained in X-250 sheet rolled at 250 °C, exhibiting the YS, UTS and EL of ~ 290 MPa, ~ 304 MPa and 11.6%, respectively. The ultra-fine grains, solute segregations and the intensified basal texture play the critical roles together.

Similar content being viewed by others

References

M. Wang, B.B. He, and M.X. Huang, Strong and Ductile Mg Alloys Developed by Dislocation Engineering, J. Mater. Sci. Technol., 2019, 35(3), p 394–395.

Q. Liu, J. Song, H. Zhao, B. Xiao, X. Zheng, and F. Pan, Improved Edge Quality for AZ31 Sheets Using Online Heating Rolling Technique, J. Mater. Eng. Perform., 2020, 29, p 4212.

H. Aghamohammadi, S.J. Hosseinipour, S.M. Rabiee, and R. Jamaati, Influence of Crystallographic Texture on the Corrosion Product Morphology and Corrosion Rate of AZ31 Plate in Simulated Body Fluid, J. Mater. Eng. Perform., 2020, 29(6), p 3824–3830.

Q. Wang, B. Jiang, A. Tang, J. Fu, Z. Jiang, H. Sheng, D. Zhang, G. Huang, and F. Pan, Unveiling Annealing Texture Formation and Static Recrystallization Kinetics of Hot-Rolled Mg-Al-Zn-Mn-Ca Alloy, J. Mater. Sci. Technol., 2020, 43, p 104–118.

K. Guan, F. Meng, P. Qin, Q. Yang, D. Zhang, B. Li, W. Sun, S. Lv, Y. Huang, N. Hort, J. Meng, Effects of Samarium Content on Microstructure and Mechanical Properties of Mg–0.5Zn–0.5Zr Alloy. J. Mater. Sci. Technol., 35(7), 1368-1377 (2019)

M.Z. Bian, T.T. Sasaki, B.C. Suh, T. Nakata, S. Kamado, and K. Hono, A Heat-Treatable Mg–Al–Ca–Mn–Zn Sheet Alloy with Good Room Temperature Formability, Scripta Mater., 2017, 138, p 151–155.

M. Zha, H.-M. Zhang, C. Wang, H.-Y. Wang, E.-B. Zhang, and Q.-C. Jiang, Prominent Role of a High Volume Fraction of Mg17Al12 Particles on Tensile Behaviors of Rolled Mg–Al–Zn Alloys, J. Alloys Compd., 2017, 728, p 682–693.

C. Xu, M.Y. Zheng, S.W. Xu, K. Wu, E.D. Wang, S. Kamado, G.J. Wang, and X.Y. Lv, Ultra High-Strength Mg–Gd–Y–Zn–Zr Alloy Sheets Processed by Large-Strain Hot Rolling and Ageing, Mater. Sci. Eng. A, 2012, 547, p 93–98.

J. Jiang, J. Wu, S. Ni, H. Yan, and M. Song, Improving the Mechanical Properties of a ZM61 Magnesium Alloy by Pre-Rolling and High Strain Rate Rolling, Mater. Sci. Eng. A, 2018, 712, p 478–484.

C. Chen, J. Chen, H. Yan, B. Su, M. Song, and S. Zhu, Dynamic Precipitation, Microstructure and Mechanical Properties of Mg-5Zn-1Mn Alloy Sheets Prepared by High Strain-Rate Rolling, Mater. Design, 2016, 100, p 58–66.

S.Q. Zhu, H.G. Yan, J.H. Chen, Y.Z. Wu, Y.G. Du, and X.Z. Liao, Fabrication of Mg-Al-Zn-Mn Alloy Sheets with Homogeneous Fine-Grained Structures Using High Strain-Rate Rolling in a Wide Temperature Range, Mater. Sci. Eng. A, 2013, 559, p 765–772.

J. Li, D. Xie, H. Yu, R. Liu, Y. Shen, X. Zhang, C. Yang, L. Ma, H. Pan, and G. Qin, Microstructure and Mechanical Property of Multi-Pass Low-Strain Rolled Mg-Al-Zn-Mn Alloy Sheet, J. Alloys Compd., 2020, 835, p 155228.

T. Nakata, C. Xu, K. Suzawa, K. Yoshida, N. Kawabe, and S. Kamado, Enhancing Mechanical Properties of Rolled Mg-Al-Ca-Mn Alloy Sheet by Zn Addition, Mater. Sci. Eng. A, 2018, 737, p 223–229.

J. Li, A. Zhang, H. Pan, Y. Ren, Z. Zeng, Q. Huang, C. Yang, L. Ma, G. Qin, Effect of Extrusion Speed on Microstructure and Mechanical Properties of the Mg-Ca Binary Alloy. J. Magnes. Alloys, https://doi.org/10.1016/j.jma.2020.05.011 (2020)

J.H. Lee, B.J. Kwak, T. Kong, S.H. Park, and T. Lee, Improved Tensile Properties of AZ31 Mg Alloy Subjected to Various Caliber-Rolling Strains, J. Magnes. Alloys, 2019, 7(3), p 381–387.

H. Huang, H. Liu, C. Wang, J. Sun, J. Bai, F. Xue, J. Jiang, and A. Ma, Potential of Multi-Pass ECAP on Improving the Mechanical Properties of a High-Calcium-Content Mg-Al-Ca-Mn Alloy, J Magnes. Alloys, 2019, 7(4), p 617–627.

R. Cheng, M. Li, S. Du, H. Pan, Y. Liu, M. Gao, X. Zhang, Q. Huang, C. Yang, L. Ma, G. Qin, Effects of Single-Pass Large-Strain Rolling on Microstructure and Mechanical Properties of Mg-Al-Ca Alloy Sheet. Mater. Sci. Eng. A, https://doi.org/10.1016/j.msea.2020.139332 (2020)

H.Y. Wang, J. Rong, G.J. Liu, M. Zha, C. Wang, D. Luo, and Q.C. Jiang, Effects of Zn on the Microstructure and Tensile Properties of As-Extruded Mg-8Al-2Sn Alloy, Mater. Sci. Eng. A, 2017, 698, p 249–255.

A. Zhang, R. Kang, L. Wu, H. Pan, H. Xie, Q. Huang, Y. Liu, Z. Ai, L. Ma, Y. Ren, and G. Qin, A New Rare-Earth-Free Mg-Sn-Ca-Mn Wrought Alloy with Ultra-High Strength and Good Ductility, Mater. Sci. Eng. A., 2019, 754, p 269–274.

J. She, P. Peng, L. Xiao, A.T. Tang, Y. Wang, and F.S. Pan, Development of High Strength and Ductility in Mg–2Zn Extruded Alloy by High Content Mn-Alloying, Mater. Sci. Eng. A, 2019, 765, p 138203.

Z.T. Li, X.G. Qiao, C. Xu, X.Q. Liu, S. Kamado, M.Y. Zheng, Enhanced Strength by Precipitate Modification in Wrought Mg–Al–Ca Alloy with Trace Mn Addition. J. Alloys Compd., https://doi.org/10.1016/j.jallcom.2020.154689 (2020)

C. Xu, T. Nakata, G.H. Fan, X.W. Li, G.Z. Tang, and S. Kamado, Enhancing Strength and Creep Resistance of Mg–Gd–Y–Zn–Zr Alloy by Substituting Mn for Zr, J. Magnes. Alloys, 2019, 7(3), p 388–399.

S.A. Khan, Y. Miyashita, Y. Mutoh, and Z.B. Sajuri, Influence of Mn Content on Mechanical Properties and Fatigue Behavior of Extruded Mg Alloys, Mater. Sci. Eng. A, 2006, 420(1–2), p 315–321.

Y. Chai, B. Jiang, J. Song, B. Liu, G. Huang, D. Zhang, F. Pan, Effects of Zn and Ca Addition on Microstructure and Mechanical Properties of as-Extruded Mg-1.0Sn Alloy Sheet. Mater. Sci. Eng. A, 746, 82-93 (2019)

Y.Z. Du, X.G. Qiao, M.Y. Zheng, K. Wu, S.W. Xu, The Microstructure, Texture and Mechanical Properties of Extruded Mg–5.3Zn–0.2Ca–0.5Ce (wt.%) Alloy. Mater. Sci. Eng. A, 620, 164-171 (2015)

Y. Chai, C. He, B. Jiang, J. Fu, Z. Jiang, Q. Yang, H. Sheng, G. Huang, D. Zhang, F. Pan, Influence of Minor Ce Additions on the Microstructure and Mechanical Properties of Mg-1.0Sn-0.6Ca Alloy. J. Mater. Sci. Technol., 37, 26-37 (2020)

H. Pan, R. Kang, J. Li, H. Xie, Z. Zeng, Q. Huang, C. Yang, Y. Ren, and G. Qin, Mechanistic Investigation of a Low-Alloy Mg–Ca-Based Extrusion Alloy with High Strength-Ductility Synergy, Acta Mater., 2020, 186, p 278–290.

X.-Y. Xu, Y.-F. Wang, H.-Y. Wang, T. Wang, M. Zha, Z.-M. Hua, C. Wang, and Q.-C. Jiang, Influences of Pre-Existing Mg17Al12 Particles on Static Recrystallization Behavior of Mg-Al-Zn Alloys at Different Annealing Temperatures, J. Alloys Compd., 2019, 787, p 1104–1109.

H. Pan, G. Qin, Y. Huang, Y. Ren, X. Sha, X. Han, Z.-Q. Liu, C. Li, X. Wu, H. Chen, C. He, L. Chai, Y. Wang, and J.-F. Nie, Development of Low-Alloyed and Rare-Earth-Free Magnesium Alloys Having Ultra-High Strength, Acta Mater., 2018, 149, p 350–363.

H. Pan, C. Yang, Y. Yang, Y. Dai, D. Zhou, L. Chai, Q. Huang, Q. Yang, S. Liu, Y. Ren, and G. Qin, Ultra-Fine Grain Size and Exceptionally High Strength in Dilute Mg–Ca Alloys Achieved by Conventional One-Step Extrusion, Mater. Lett., 2019, 237, p 65–68.

Z. Yang, M.F. Chisholm, G. Duscher, X. Ma, and S.J. Pennycook, Direct Observation of Dislocation Dissociation and Suzuki Segregation in a Mg–Zn–Y Alloy by Aberration-Corrected Scanning Transmission Electron Microscopy, Acta Mater., 2013, 61(1), p 350–359.

Z.R. Zeng, Y.M. Zhu, S.W. Xu, M.Z. Bian, C.H.J. Davies, N. Birbilis, and J.F. Nie, Texture Evolution during Static Recrystallization of Cold-Rolled Magnesium Alloys, Acta Mater., 2016, 105, p 479–494.

M.Z. Bian, T.T. Sasaki, T. Nakata, Y. Yoshida, N. Kawabe, S. Kamado, and K. Hono, Bake-Hardenable Mg–Al–Zn–Mn–Ca Sheet Alloy Processed by Twin-Roll Casting, Acta Mater., 2018, 158, p 278–288.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans, 2005, 46(12), p 2817–2829.

N.J. Petch, The cleavage strength of polycrystals, J Iron Steel Inst, 1953, 174, p 25–28.

D. Liu, Z.-Y. Liu, and E.-D. Wang, Evolution of Twins and Texture and its Effects on Mechanical Properties of AZ31 Magnesium Alloy Sheets under Different Rolling Process Parameters, Trans. Nonferrous Metals Soc. China, 2015, 25(11), p 3585–3594.

C. Xu, M.Y. Zheng, K. Wu, E.D. Wang, G.H. Fan, S.W. Xu, S. Kamado, X.D. Liu, G.J. Wang, and X.Y. Lv, Influence of Rolling Temperature on the Microstructure and Mechanical Properties of Mg–Gd–Y–Zn–Zr Alloy Sheets, Mater. Sci. Eng. A, 2013, 559, p 615–622.

Acknowledgment

This work is supported by the National Natural Science Foundation of China, China (Nos. U1610253 and 51971053) and fund from Project of Promoting Talents in Liaoning province, China (No. XLYC1808038). H.C. Pan acknowledges the financial assistance from the Young Elite Scientists Sponsorship Program by CAST (2019-2021RNRC001, 2019-2021QNRC002), the State Key Laboratory of Solidification Processing in NPU, China (No. SKLSP201920), the Fundamental Research Fund for the Central University, China (No. N2002011), and Joint Research Fund Liaoning-Shenyang National Laboratory for Materials Science, China (No. 2019JH3/30100040).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, H., Cheng, R., Du, S. et al. Achieving High Strength in Micro-alloyed Mg-Al-Ca-Zn-Mn-Ce Alloy Sheet Processed by Single-Pass Large-Strain Rolling. J. of Materi Eng and Perform 29, 7115–7124 (2020). https://doi.org/10.1007/s11665-020-05188-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05188-9