Abstract

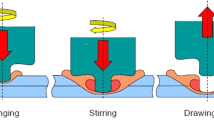

The friction stir vibration welding (FSVW) method has been proposed as a modified version of the friction stir welding (FSW) method. In the current research, the effect of the FSVW variables on the microstructure and the mechanical properties of the joint made by this welding process was analyzed. In FSVW, the workpiece is vibrated normal to tool traverse direction while FSW is carried out. AA6061-T6 specimens were joined by FSVW as well as FSW, and the obtained joints were compared. The microstructures of the welds were analyzed using metallography techniques. SEM and EBSD were also applied to study the microstructure. The results showed that grain size reduced and hardness increased as the FSVW technique was employed instead of FSW. The results also indicated that the strength and hardness of joints, made by FSVW, increased as vibration frequency increased. It is believed that workpiece vibration, in FSVW, increases the material strain and correspondingly, enhances the dislocation density. More intensified role of dynamic recrystallization in FSVW, compared to FSW, leads to the development of finer grains in the stir zone. It was also concluded that high thermal energy during FSW and FSVW might deteriorate the mechanical properties of the joint and low thermal energy also leads to an unfair joint.

Similar content being viewed by others

References

M. Abbasi, B. Bagheri, and R. Keivani, Thermal Analysis of Friction Stir Welding Process and Investigation into Affective Parameters Using Simulation, J. Mech. Sci. Technol., 2015, 29(2), p 861–866

M. Jafari, M. Abbasi, D. Poursina, A. Gheysarian, and B. Bagheri, Characterization of Microstructure and Mechanical Properties of Dissimilar Steel- Copper joint Made by FSW, J. Mech. Sci. Technol., 2017, 31(3), p 1135–1142

H. Zhang, M. Wang, W. Zhou, X. Zhang, Z. Zhu, T. Yu, and G. Yang, Microstructureproperty Characteristics of a Novel Non-Weld-Thinning Friction Stir Welding Process of Aluminum Alloys, Mater. Des., 2015, 86, p 379–387

O. Barooni, M. Givi, M. Abbasi, and B. Bagheri, New Method to Improve the Microstructure and Mechanical Properties of joint Obtained using FSW, In. J. Adv. Manufac. Technol., 2017, 93(9–12), p 4371–4378

R. Keivani, B. Bagheri, F. Sharifi, M. Ketabchi, and M. Abbasi, Effects of Pin Angle and Preheating on Temperature Distribution during Friction Stir Welding Operation, Trans. Nonferrous Met. Soc. China, 2013, 23(9), p 2708–2713

G. Cam and S. Mistikoglu, Recent Developments in Friction Stir Welding of Al-Alloys, J. Mater. Eng. Perform., 2014, 23, p 1936–1953

R.I. Rodriguez, J.B. Jordon, P.G. Allison, T. Rushing, and L. Garcia, Microstructure and Mechanical Properties of Dissimilar Friction Stir Welding of 6061-to-7050 Aluminum Alloys, Mater. Des., 2015, 83, p 60–65

S. Rajakumar, C. Muralidharan, and V. Balbasubramanian, Predicting Tensile Strength, Hardness and Corrosion Rate of Friction Stir Welded AA6061-T6 Aluminum Alloy Joints, Mater. Des., 2011, 32, p 2878–2890

A. Salemi Golezani, R. Vatankhah Barenji, A. Heidarzedh, and H. Pouraliakbar, Elucidating of Tool Rotational Speed in Friction Stir Welding of 7020-T6 Aluminum Alloy, Int. J. Adv. Manufac. Technol, 2015, 81, p 1155–1164

A. Heidarzade, H. Khodaverdizadeh, A. Mahmoudi, and E. Nazari, Tensile Behaviour of Friction Stir Welded AA 6061-T4 Aluminium Alloy Joints, Mater. Des., 2012, 37, p 166–173

B. Wang, B. Lei, J. Zhu, Q. Feng, L. Wang, and D. Wu, EBSD Study on Microstructure and Texture of Friction Stir Welded AA5052-O and AA6061-T6 Dissimilar Joint, Mater. Des., 2015, 87, p 593–599

S.K. Park, S.T. Hong, J.H. Park, K.Y. Park, Y.J. Kwon, and H.J. Son, Effect of Material Locations on Properties of Friction Stir Welding Joints of Dissimilar Aluminium Alloys, Sci. Technol. Weld Join., 2010, 15, p 331–336

I. Vysotskiy, S. Malopheyev, S. Mironov, and R. Kaibyshev, Pre-Strain Rolling as an Effective Tool for Suppression of Abnormal Grain Growth in Friction-Stir Welded 6061 Aluminum Alloy, Mater. Sci. Eng., A, 2018, 733, p 39–42

S. Malopheyev, I. Vysotskiy, V. Kulitskiy, S. Mironov, and R. Kaibyshev, Optimization of Processing-Microstructure-Properties Relationship in Friction-Stir Welded 6061-T6 Aluminum Alloy, Mater. Sci. Eng., A, 2016, 662, p 136–143

X.C. Liu, C.S. Wu, and G.K. Padhy, Improved Weld Macrosection, Microstructure and Mechanical Properties of 2024Al-T4 Butt Joints in Ultrasonic Vibration Enhanced Friction Stir Welding, Sci Technol Weld Join., 2015, 20, p 345–352

S. Amini and M.R. Amiri, Study of Ultrasonic Vibrations’ Effect on Friction Stir Welding, Int. J. Adv. Manuf. Technol., 2014, 73, p 127–135

M. Ahmadnia, A. Seidanloo, R. Teimouri, Y. Rostamiyan, and Kh.Gh. Titrashi, Determining Influence of Ultrasonic-Assisted Friction Stir Welding Parameters on Mechanical and Tribological Properties of AA6061 Joints, Int. J. Adv. Manuf. Technol., 2015, https://doi.org/10.1007/s00170-015-6784-0

Zh Liu, Sh Ji, and X. Meng, Joining of Magnesium and Aluminum Alloys via Ultrasonic Assisted Friction Stir Welding at Low Temperature, Int. J. Adv. Manuf. Technol., 2018, 97, p 4127–4136

M. Rahmi and M. Abbasi, Friction Stir Vibration Welding Process: Modified Version of Friction Stir Welding Process, Int. J. Adv. Manuf. Technol., 2017, 90, p 141–151

ASTM E3–11, Standard Guide for Preparation of Metallographic Specimens, ASTM International, West Conshohocken, PA, 2011

ASTM-E112–13, Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA, 2011

ASTM-E8, Standard Test Methods of Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA, 2011

A. Heidarzadeh, T. Saeid, and V. Klemm, Microstructure, Texture, and Mechanical Properties of Friction Stir Welded Commercial Brass Alloy, Mater. Charact., 2016, 119, p 84–91

A. Heidarzadeh, H. Pouraliakbar, S. Mahdavi, and M.R. Jandaghi, Ceramic Nanoparticles Addition in Pure Copper Plate: FSP Approach, Microstructure Evolution and Texture Study Using EBSD, Ceramic Int. J., 2018, 44, p 3128–3133

A. Amirafshar and H. Pouraliakbar, Effect of Tool Pin Design on the Microstructural Evolutions and Tribological Characteristics of Friction Stir Processed Structural Steel, Measure. J., 2015, 68, p 111–116

Y.S. Sato, M. Urata, and H. Kokawa, Parameters Controlling Microstructure and Hardness During Friction Stir Welding of Precipitation-Hardenable Aluminum Alloy 6063, Metal. Mater. Trans. A., 2002, 33, p 625–635

B. Bagheri, A.A.M. Rizi, M. Abbasi, and M. Givi, Friction Stir Spot Vibration Welding: Improving the Microstructure and Mechanical Properties of Al5083, Joint Metal. Micro. Analyse., 2019, 8(5), p 713–725

M. Abbasi, M. Givi, and A. Ramazani, Friction Stir Vibration Processing: A New Method to Improve the Microstructure and Mechanical Properties of Al5052/SiC Surface Nano-Composite Layer, Int. J. Adv. Manuf. Technol., 2019, 100, p 1463–1473

C.I. Chang, C.J. Lee, and J.C. Huang, Relationship Between Grain Size and Zener-Holloman Parameter During Friction Stir Processing in AZ31 Mg Alloys, Script. Mater, 2004, 51, p 509–514

S. Fouladi and M. Abbasi, The Effect of Friction Stir Vibration Welding Process on Characteristics of SiO2 Incorporated Joint, J. Mater. Process. Technol., 2017, 243, p 23–30

B. Bagheri, M. Abbasi, and M. Dadaei, Effect of Water Cooling and Vibration on the Performances of Friction Stir-Welded AA5083 Aluminum Joint, J. Metall. Micro. Analys., 2020, https://doi.org/10.1007/s13632-019-00606-4

J.Q. Su, T.W. Nelson, and C.J. Sterling, Microstructure Evolution During FSW/FSP of High Strength Aluminum Alloys, Mater. Sci. Eng., A, 2005, 405, p 277–286

B. Bagheri, M. Abbasi, A. Abdollahzadeh, and H. Omidvar, Advanced Approach to Modify Friction Stir Spot Welding Process, Metal. Mater. In. J., 2019, https://doi.org/10.1007/s12540-019-00416-x

B. Bagheri, A.A.M. Rizi, M. Abbasi, and M. Givi, Friction Stir Spot Vibration Welding: Improving the Microstructure and Mechanical Properties of Al5083 Joint, Metall. Micro. Analys., 2019, 8(5), p 713–725. https://doi.org/10.1007/s13632-019-00563-y

M. Abbasi, M. Givi, and B. Bagheri, Application of Vibration to Enhance Efficiency of Friction Stir Processing, Trans. Nonferrous Met. Soc. China, 2019, 29, p 1393–1400. https://doi.org/10.1016/S1003-6326(19)65046-6

V. Uthaisangsuk, Microstructure Based Formability Modeling of Multiphase Steels. Ph. D. Thesis, IEHK, RWTH- Aachen, 2009.

D. Hull and D.J. Bacon, Introduction to Dislocations, Butterworth-Heinemann, Britain, 2011, p 87–95

G.E. Dieter and D. Bacon, Mechanical and Metallurgy, McGraw-Hill, London, 1988, p 184–193

B. Bagheri and M. Abbasi, Development of AZ91/SiC Surface Composite by FSP: Effect of Vibration and Process Parameters on Microstructure and Mechanical Characteristics, Adv. Manuf., 2019, https://doi.org/10.1007/s40436-019-00288-9

Y.Z. Estrin, P.A. Zabrodin, I.S. Braude, T.V. Grigorova, N.V. Iasev, V.V. Pustovalov, V.S. Fomenko, and S.E. Shumilin, Low Temperature Plastic Deformation of AZ31 Magnesium Alloy with Different Microstructures, Low. Tempe. Phys., 2010, 36, p 1100–1112

M. Naderi, M. Abbasi, and A. Saeed-Akbari, Enhanced Mechanical Properties of a Hot-Stamped Advanced High-Strength Steel Via Tempering Treatment, Metall. Mater. Trans. A, 2013, 44, p 1852–1861

S. Kumar, Ultrasonic Assisted Friction Stir Processing of 6063 Aluminum Alloy, Arch. Civ. Mech. Eng., 2016, 16, p 473–484

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R Reports, 2005, 50(12), p 1–78

Acknowledgments

The authors would like to thank the University of Kashan and Amirkabir University of Technology (AUT) for partially providing laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bagheri, B., Abbasi, M. & Dadaei, M. Mechanical Behavior and Microstructure of AA6061-T6 Joints Made by Friction Stir Vibration Welding. J. of Materi Eng and Perform 29, 1165–1175 (2020). https://doi.org/10.1007/s11665-020-04639-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04639-7