Abstract

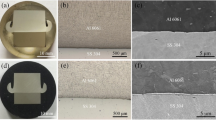

In this paper, 3003Al and TC4 sheets were welded by magnetic pulse welding. The mechanical properties and microstructure of Al/Ti joints were investigated. The results showed that the mechanical properties of welding joints could be enhanced by the increasing effective welded area and transition layer average thickness. Three bonding types were observed in the weld interfaces: solid-state bonding, solid–liquid coexistence state bonding and liquid-state bonding. Three distinct types of defects: cracks along the welding direction, cracks across the diffusion layer, micron-sized pores and shrinkage cracks, occurred in the Al/Ti interfaces with different bonding types. The XRD results showed that TiAl3 and Ti3Al were generated in the weld interface. The cleavage fracture, parabolic dimples and orthogonal dimples existed in the failure surface of different locations.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

S.Y. Chang, L.C. Tsao, Y.H. Lei, S.M. Mao, and C.H. Huang, Brazing of 6061 Aluminum Alloy/Ti-6Al-4V Using Al-Si-Cu-Ge Filler Metals, J. Mater. Process. Tech., 2012, 212, p 8–14

N. Kazantseva, P. Krakhmalev, M. Thuvander, I. Yadroitsev, N. Vinogradova, and I. Ezhov, Martensitic Transformations in Ti-6Al-4V (ELI) Alloy Manufactured by 3D Printing, Mater. Charact., 2018, 146, p 101–112

S.Z. Wei, Y.J. Li, J. Wang, and K. Liu, Formation of Brittle Phase During Pulse Current Gas Tungsten Arc Welding of Titanium to Aluminum Alloys, J. Mater. Eng. Perform., 2014, 23(4), p 1451–1457

S.H. Chen, X.C. Huo, C.X. Guo, X. Wei, J.H. Huang, J. Yang, and S.B. Lin, Interfacial Characteristics of Ti/Al Joint by Vaporizing Foil Actuator Welding, J. Mater. Process. Tech., 2019, 263, p 73–81

A. Kar, S.V. Kailas, and S. Suwas, Effect of Zinc Interlayer in Microstructure Evolution and Mechanical Properties in Dissimilar Friction Stir Welding of Aluminum to Titanium, J. Mater. Eng. Perform., 2018, 27(11), p 6016–6026

D.M. Fronczek, R. Chulist, L. Litynska-Dobrzynska, Z. Szulc, P. Zieba and J. Wojewoda-Budka, Microstructure Changes and Phase Growth Occurring at the Interface of the Al/Ti Explosively Welded and Annealed Joints. J. Mater. Eng. Perform., 25(8), 3211-3217

I.A. Bataev, A.A. Bataev, V.I. Mali, and D.V. Pavliukova, Structural and Mechanical Properties of Metallic-Intermetallic Laminate Composites Produced by Explosive Welding and Annealing, Mater. Des., 2012, 35, p 225–234

A.N. AlHazaa and T.I. Khan, Diffusion Bonding of Al7075 to Ti-6Al-4V Using Cu Coatings and Sn-3.6Ag-1Cu Interlayers, J. Alloy Compd., 2010, 494, p 351–358

Y.C. Chen and K. Nakata, Microstructural Characterization and Mechanical Properties in Friction Stir Welding of Aluminum and Titanium Dissimilar Alloys, Mater. Des., 2009, 30, p 469–474

C.Q. Zhang, J.D. Robson, and P.B. Prangnell, Dissimilar Ultrasonic Spot Welding of Aerospace Aluminum Alloy AA2139 Titanium Alloy TiAl6V4, J. Mater. Process. Tech., 2016, 231, p 382–388

C.Q. Zhang, J.D. Robson S.J. Haigh and P.B. Prangnell, Interfacial Segregation of Alloying Elements During Dissimilar Ultrasonic Welding of AA6111 Aluminum and Ti6Al4V Titanium, Metall. and Mat. Trans. A, 2019, 50, p 5143

C.Q. Zhang and W. Liu, Abnormal Effect of Temperature on Intermetallic Compound Layer Growth at Aluminum-Titanium Interface: The Role of Grain Boundary Diffusion, Mater. Lett., 2019, 254, p 1–4

C.Q. Zhang and W. Liu, Non-parabolic Al3Ti Intermetallic Layer Growth on Aluminum-Titanium Interface at Low Annealing Temperatures, Mater. Lett., 2019, 256, p 126624

M. Mirjalili, M. Soltanieh, K. Matsuura, and M. Ohno, On the Kinetics of TiAl3 Intermetallic Layer Formation in the Titanium and Aluminum Diffusion Couple, Intermetallics, 2013, 32, p 297–302

M.S. Kenevisi and S.M. Mousavi Khoie, A Study on the Effect of Bonding Time on the Properties of Al7075 to Ti-6Al-4V Diffusion Bonded Joint, Mater. Lett., 2012, 76, p 144-146

Z.H. Song, K. Nakata, A. Wu, J.S. Liao, and L. Zhou, Influence of Probe Offset Distance on Interfacial Microstructure and Mechanical Properties of Friction Stir Butt Welded Joint of Ti6Al4V and A6061 Dissimilar Alloys, Mater. Des., 2014, 57, p 269–278

U. Dressler, G. Biallas, and U. Alfaro, Mercado, Friction Stir Welding of Titanium Alloy Ti6Al4V to Aluminium Alloy AA2024-T3, Mater. Sci. Eng. A., 2009, A526, p 113–117

C.Q. Zhang, J.D. Robson, O. Ciuca, and P.B. Prangnell, Microstructure Characterization and Mechanical Properties of High Power Ultrasonic Spot Welded Aluminum Alloy AA6111-TiAl6V4, Mater. Charact., 2014, 97, p 83–91

A. Kapil and A. Sharma, Magnetic Pulse Welding: An Efficient and Environmentally Friendly Multi-Material Joining Technique, J. Clean. Prod., 2015, 100, p 35–58

S.D. Kore, P.P. Date, and S.V. Kulkarni, Electromagnetic Impact Welding of Aluminum to Stainless Steel Sheets, J. Mater. Process. Tech., 2008, 208(1–3), p 486–493

J.J. Cui, T. Sun, H.H. Geng, W. Yuan, G.Y. Li, and X. Zhang, Effect of Surface Treatment on the Mechanical Properties and Microstructures of Al/Fe Single-lap Joint by Magnetic Pulse Welding, Int. J. Adv. Manuf. Technol., 2018, 98, p 1081–1092

V. Psyk, C. Scheffler, M. Linnemann, and D. Landgrebe, Process Analysis for Magnetic Pulse Welding of Similar and Dissimilar Material Sheet Metal Joints, Procedia Engineering, 2017, 207, p 353–358

M.A. Moghaddas, A. Abdollah-zadeh, and M. Hajian, The Effects of Back-plate Support and Welded Metal Type on the Characteristics of Joints Produced by Magnetic Pulse Welding, Int. J. Adv. Manuf. Technol., 2019, 102, p 379–392

R.N. Raoelison, N. Buiron, M. Rachik, D. Haye, and G. Franz, Efficient Welding Conditions in Magnetic Pulse Welding Process, J. Manuf. Process., 2012, 14(3), p 372–377

A.P. Manogaran, P. Manoharan, D. Priem, S. Marya, and G. Racineux, Magnetic Pulse Spot Welding of Bimetals, J. Mater. Process. Tech., 2014, 214(6), p 1236–1244

J.J. Cui, Y. Li, Q.X.X. Liu, X. Zhang, Z.D. Xu, and G.Y. Li, Joining of Tubular Carbon Fiber-Reinforced Plastic/Aluminum by Magnetic Pulse Welding, J. Mater. Process. Tech., 2019, 264, p 273–282

Y. Zhang, S.S. Babu, and G.S. Daehn, Interfacial Ultrafine-grained Structures on Aluminum Alloy 6061 Joint and Copper Alloy 110 Joint Fabricated by Magnetic Pulse welding, J. mater. Sci., 2010, 45, p 4645–4651

I.V. Oliveira, A.J. Cavaleiro, G.A. Taber, and A. Reis, Magnetic Pulse Welding of Dissimilar Materials: Aluminum-Copper, Springer international publishing, Materials Design and Applications, 2017

A. Stern, M. Aizenshtein, G. Moshe, S.R. Cohen, and N. Frage, The Nature of Interfaces in Al-1050/Al-1050 and Al-1050/Mg-AZ31 Couples Joined by Magnetic Pulse Welding (MPW), J. Mater. Eng. Perform., 2013, 22(7), p 2013–2099

A. Stern, V. Shribman, A. Ben-Artzy, and M. Aizenshtein, Interface Phenomena and Bonding Mechanism in Magnetic Pulse Welding, J. Mater. Eng. Perform., 2014, 23(10), p 3449–3458

A. Ben-Artzy, A. Stern, N. Frage, V. Shribman, and O. Sadot, Wave Formation Mechanism in Magnetic Pulse Welding, Int. J. Impact Eng., 2010, 37(4), p 397–404

S. Patra, K.S. Arora, M. Shome, and S. Bysakh, Interface Characteristics and Performance of Magnetic Pulse Welded Copper-Steel Tubes, J. Mater. Process. Tech., 2017, 245, p 278–286

H.H. Geng, Z.H. Xia, X. Zhang, G.Y. Li, and J.J. Cui, Microstructures and Mechanical Properties of the Welded AA5182/HC340LA Joint by Magnetic Pulse Welding, Mater. Charact., 2018, 138, p 229–237

S.J. Chen and X.Q. Jiang, Microstructure Evolution during Magnetic Pulse Welding of Dissimilar Aluminium and Magnesium Alloys, J. Manuf. Process., 2015, 19, p 14–21

T. Itoi, A.B. Mohamad, R. Suzuki, and K. Okagawa, Microstructure Evolution of a Dissimilar Junction Interface Between an Al Sheet and a Ni-Coated Cu Sheet Joined by Magnetic Pulse Welding, Mater. Charact., 2016, 118, p 142–148

R.N. Raoelison, D. Racine, Z. Zhang, N. Buiron, D. Marceau, and M. Rachik, Magnetic Pulse Welding: Interface of Al/Cu Joint and Investigation of Intermetallic Formation Effect on the Weld Features, J. Manuf. Process., 2014, 16(4), p 427–434

A. Ben-Artzy, A. Stern, N. Frage, and V. Shribman, Interface Phenomena in Aluminium-Magnesium Magnetic Pulse Welding, Sci. Technol. Weld. Joi., 2008, 13(4), p 402–408

P. Ghosh, S. Patra, S. Chatterjee, and M. Shome, Microstructural Evaluation of Magnetic Pulse Welded Plain Carbon Steel Sheets, J. Mater. Process. Tech., 2018, 254, p 25–37

Y. Zhang, S.S. Babu, P. Zhang, E.A. Kenik, and G.S. Daehn, Microstructure Characterisation of Magnetic Pulse Welded AA6061-T6 by Electron Backscattered Diffraction, Sci. Technol. Weld. Joi., 2008, 13(5), p 467–471

T. Sapanathan, R.N. Raoelison, N. Buiron, and M. Rachik, In Situ Metallic Porous Structure Formation due to Ultra-High Heating and Cooling Rates during an Electromagnetic Pulse Welding, Scripta. Mater., 2017, 128, p 10–13

H. Okamoto, Binary Alloy Phase Diagrams Updating Service, ASM International, Ohio, 1992

U.R. Kattner, J.C. Lin, and Y.A. Chang, Thermodynamic Assessment and Calculation of the Ti-Ai System, Metall. Trans. A, 1992, 23(8), p 2081–2090

Q.J. Sun, J.Z. Li, Y.B. Liu, B.P. Li, P.W. Xu, and J.C. Feng, Microstructural Characterization and Mechanical Properties of Al/Ti Joint Welded by CMT Method-Assisted Hybrid Magnetic Field, Mater. Des., 2017, 116, p 316–324

W. Yao, A.P. Wu, G.S. Zou, and J.L. Ren, Formation Process of the Bonding Joint in Ti/Al Diffusion Bonding, Mat. Sci. Eng. A, 2008, 480(1–2), p 456–463

J.W. Choi, H.H. Liu, and H. Fujii, Dissimilar Friction Stir Welding of Pure Ti and Pure Al, Mat. Sci. Eng. A, 2018, 730, p 168–176

Acknowledgments

This project is supported by the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (51621004) and the Key Research and Development Program of Hunan Province (2017GK2090).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, J., Ye, L., Zhu, C. et al. Mechanical and Microstructure Investigations on Magnetic Pulse Welded Dissimilar AA3003-TC4 Joints. J. of Materi Eng and Perform 29, 712–722 (2020). https://doi.org/10.1007/s11665-019-04542-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04542-w