Abstract

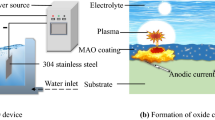

Microarc oxidized coatings on Ti6Al4V alloy are produced in a basic Na2SiO3-(NaPO3)6-NaAlO2 electrolyte with different concentrations of sodium tungstate. The effects of sodium tungstate on the characteristics of the coating are investigated through current–time response, microstructure, composition, hardness, bonding strength and antifriction measurements. The coating is mainly composed of Al2TiO5, TiO2, Al2O3 and amorphous substances regardless of the concentration of sodium tungstate. The sodium tungstate is transformed into trace amounts of WO3, which significantly promotes the growth of the coatings. The bonding strength and antifriction performance of the coatings are enhanced with the concentration of sodium tungstate less than 4 g/L, whereas excessive sodium tungstate results in a coarse outer layer with more microdefects, which deteriorates the wear resistance of the coating. Based on the results of scratch and wear test with energy-dispersive x-ray spectroscopy of the worn surface and debris, the optimal concentration of sodium tungstate doped into the electrolyte is identified, and this concentration yields superior tribological property. Excellent wear resistance is achieved by combining a high bonding strength and hardness with a less defective outer layer.

Similar content being viewed by others

References

A. Gebert, D. Eigel, P.F. Gostin, V. Hoffmann, M. Uhlemann, A. Helth, S. Pilz, R. Schmidt, M. Calin, M. Göttlicher, M. Rohnke, and J. Janek, Oxidation Treatments of Beta-Type Ti-40Nb for Biomedical Use, Surf. Coat. Technol., 2016, 302, p 88–99

M. Kastenhuber, B. Rashkova, H. Clemens, and S. Mayer, Effect of Microstructural Instability on the Creep Resistance of an Advanced Intermetallic γ-TiAl Based Alloy, Intermetallics, 2017, 80, p 1–9

M.S. Selim, S.A. El-Safty, M.A. El-Sockary, A.I. Hashem, O.M.A. Elenien, A.M. El-Saeed, and N.A. Fatthallah, Smart Photo-Induced Silicone/TiO2 Nanocomposites with Dominant [110] Exposed Surfaces for Self-Cleaning Foul-Release Coatings of Ship Hulls, Mater. Des., 2016, 101, p 218–225

S. Hariprasad, M. Ashfaq, T. Arunnellaiappan, M. Harilal, and N. Rameshbabu, Role of Electrolyte Additives on In-Vitro Corrosion Behavior of DC Plasma Electrolytic Oxidization Coatings Formed on Cp-Ti, Surf. Coat. Technol., 2016, 292, p 20–29

C.J. Hu and P.H. Chiu, Wear and Corrosion Resistance of Pure Titanium Subjected to Aluminization and Coated with a Microarc Oxidation Ceramic Coating, Int. J. Electrochem. Sci., 2015, 10, p 4290–4302

A.F. Yetim, Investigation of Wear Behavior of Titanium Oxide Films, Produced by Anodic Oxidation, on Commercially Pure Titanium in Vacuum Conditions, Surf. Coat. Technol., 2010, 205, p 1757–1763

T. Dikici and M. Toparli, Microstructure and Mechanical Properties of Nanostructured and Microstructured TiO2 Films, Mater. Sci. Eng., A, 2016, 661, p 19–24

H.X. Liu, Q. Xu, X.W. Zhang, C.Q. Wang, and B.Y. Tang, Wear and Corrosion Behaviors of Ti6Al4V Alloy Biomedical Materials by Silver Plasma Immersion Ion Implantation Process, Thin Solid Films, 2012, 521, p 89–93

C.W. Chan, S. Lee, G. Smith, G. Sarri, C.H. Ng, A. Sharba, and H.C. Man, Enhancement of Wear and Corrosion Resistance of Beta Titanium Alloy by Laser Gas Alloying with Nitrogen, Appl. Surf. Sci., 2016, 367, p 80–90

V.S. Viteri, G. Barandika, R. Bayón, X. Fernández, I. Ciarsolo, A. Igartua, R.P. Tanoira, J.E. Moreno, and C.P. Peremarch, Development of Ti–C–N Coatings with Improved Tribological Behavior and Antibacterial Properties, J. Mech. Behav. Biomed. Mater., 2016, 55, p 75–86

E. Urbańczyk, A. Krząkała, A. Kazek-Kęsik, J. Michalska, A. Stolarczyk, G. Dercz, and W. Simka, Electrochemical Modification of Ti–13Nb–13Zr Alloy Surface in Phosphate Based Solutions, Surf. Coat. Technol., 2016, 291, p 79–88

A. Gao, R.Q. Hang, and P.K. Chu, Recent Advances in Anti-Infection Surfaces Fabricated on Biomedical Implants by Plasma-Based Technology, Surf. Coat. Technol., 2017, 312, p 2–6

O. Çomaklı, M. Yazıcı, T. Yetim, A.F. Yetim, and A. Çelik, The Effect of Calcination Temperatures on Structural and Electrochemical Properties of TiO2 Film Deposited on Commercial Pure Titanium, Surf. Coat. Technol., 2016, 285, p 298–303

L.T. Duarte, S.R. Biaggio, R.C. Rocha-Filho, and N. Bocchi, Surface Characterization of Oxides Grown on the Ti–13Nb–13Zr Alloy and Their Corrosion Protection, Corros. Sci., 2013, 72, p 35–40

J.H. Lee, J.I. Youn, Y.J. Kim, I.K. Kim, K.W. Jang, and H.J. Oh, Photocatalytic Characteristics of Boron and Nitrogen Doped Titania Film Synthesized by Micro-Arc Oxidation, Ceram. Int., 2015, 41, p 11899–11907

S.X. Wang, Q. Zhao, D.X. Liu, and N. Du, Microstructure and Elevated Temperature Tribological Behavior of TiO2/Al2O3 Composite Ceramic Coating Formed by Microarc Oxidation of Ti6Al4V Alloy, Surf. Coat. Technol., 2015, 272, p 343–349

K. Yousefipour, A. Akbari, and M.R. Bayati, The Effect of EEMAO Processing on Surface Mechanical Properties of the TiO2–ZrO2 Nanostructured Composite Coatings, Ceram. Int., 2013, 39, p 7809–7815

H.R. Masiha, H.R. Bagheri, M. Gheytani, M. Aliofkhazraei, A. Sabour Rouhaghdam, and T. Shahrabi, Effect of Surface Nanostructuring of Aluminum Alloy on Post Plasma Electrolytic Oxidation, Appl. Surf. Sci., 2014, 317, p 962–969

F.C. Chang, C.J. Wang, J.W. Lee, and B.S. Lou, Microstructure and Mechanical Properties Evaluation of Molybdenum Disulfide-Titania Nanocomposite Coatings Grown by Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2016, 303, p 68–77

B. Yin, Z.J. Peng, J. Liang, K.J. Jin, S.Y. Zhu, J. Yang, and Z.H. Qiao, Tribological Behavior and Mechanism of Self-Lubricating Wear-Resistant Composite Coatings Fabricated by One-Step Plasma Electrolytic Oxidation, Tribol. Int., 2016, 97, p 97–107

N. Ao, D.X. Liu, S.X. Wang, Q. Zhao, X.H. Zhang, and M.M. Zhang, Microstructure and Tribological Behavior of a TiO2/hBN Composite Ceramic Coating Formed Via Micro-Arc Oxidation of Ti–6Al–4 V Alloy, J. Mater. Sci. Technol., 2016, 32, p 1071–1076

J.H. Ouyang, Y.H. Wang, Z.G. Liu, Y.M. Wang, and Y.J. Wang, Preparation and High Temperature Tribological Properties of Microarc Oxidation Ceramic Coatings Formed on Ti2AlNb Alloy, Wear, 2015, 330, p 239–249

M.Q. Tang, W.P. Li, H.C. Liu, and L.Q. Zhu, Influence of K2TiF6 in Electrolyte on Characteristics of the Microarc Oxidation Coating on Aluminum Alloy, Curr. Appl. Phys., 2012, 12, p 1259–1265

Y.M. Wang, T.Q. Lei, L.X. Guo, and B.L. Jiang, Fretting Wear Behaviour of Microarc Oxidation Coatings Formed on Titanium Alloy Against Steel in Unlubrication and Oil Lubrication, Appl. Surf. Sci., 2006, 252, p 8113–8120

M. Babaei, C. Dehghanian, and M. Babaei, Electrochemical Assessment of Characteristics and Corrosion Behavior of Zr-Containing Coatings Formed on Titanium by Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2015, 279, p 79–91

D. Quintero, M.A. Gomez, J.G. Castano, E. Tsuji, Y. Aoki, F. Echeverria, and H. Habazaki, Anodic Films Obtained on Ti6Al4V in Aluminate Solutions by Spark Anodizing: Effect of OH− and WO-2 4 Additions on the Tribological Properties, Surf. Coat. Technol., 2017, 310, p 180–189

M.R. Bayati, F. Golestani-Fard, A.Z. Moshfegh, and R. Molaei, A Photocatalytic Approach in Micro Arc Oxidation of WO3–TiO2 Nano Porous Semiconductors Under Pulse Current, Mater. Chem. Phys., 2011, 128, p 427–432

M.R. Bayati, A.Z. Moshfegh, F. Golestani-Fard, and R. Molaei (WO3)x–(TiO2)1−x Nano-Structured Porous Catalysts Grown by Micro-Arc Oxidation Method: Characterization and Formation Mechanism, Mater. Chem. Phys., 2010, 124, p 203–207

J. He, Q. Luo, Q.Z. Cai, X.W. Li, and D.Q. Zhang, Microstructure and Photocatalytic Properties of WO3/TiO2 Composite Films by Plasma Electrolytic Oxidation, Mater. Chem. Phys., 2011, 129, p 242–248

A. Banerji, S. Bhowmick, and A.T. Alpas, High Temperature Tribological Behavior of W Containing Diamond-Like Carbon (DLC) Coating Against Titanium Alloys, Surf. Coat. Technol., 2014, 241, p 93–104

O.D. Greenwood, S.C. Moulzolf, P.J. Blau, and R.J. Lad, The Influence of Microstructure on Tribological Properties of WO3 Thin Films, Wear, 1999, 232, p 84–90

J. Raudoniene, A. Laurikenas, M.M. Kaba, G. Sahin, A.U. Morkan, D. Brazinskiene, S. Asadauskas, R. Seidu, A. Kareiva, and E. Garskaite, Textured WO3 and WO3: Mo Films Deposited from Chemical Solution on Stainless Steel, Thin Solid Films, 2018, 653, p 179–187

C.C. Tseng, J.L. Lee, T.H. Kuo, S.N. Kuo, and K.H. Tseng, The Influence of Sodium Tungstate Concentration and Anodizing Conditions on Microarc Oxidation (MAO) Coatings for Aluminum Alloy, Surf. Coat. Technol., 2012, 206, p 3437–3443

Q.P. Tran, Y.C. Kuo, J.K. Sun, J.L. He, and T.S. Chin, High Quality Oxide-Layers on Al-Alloy by Micro-Arc Oxidation Using Hybrid Voltages, Surf. Coat. Technol., 2016, 303, p 61–67

F.H. Chung, Quantitative Interpretation of X-ray Diffraction Patterns of Mixtures. II. Adiabatic Principle of X-ray Diffraction Analysis of Mixtures, J. Appl. Crystallogr., 1974, 7, p 526–531

L. Chen, Y. Qu, X. Yang, B. Liao, W. Xue, and W. Cheng, Characterization and First-Principles Calculations of WO3/TiO2 Composite Films on Titanium Prepared by Microarc Oxidation, Mater. Chem. Phys., 2017, 201, p 311–322

J.M. Albella, I. Montero, and J.M. Martinez-Duart, Electron injection and Avalanche During the Anodic Oxidation of Tantalum, J. Electrochem. Soc., 1984, 131, p 1101–1104

Acknowledgments

This research was supported by National Natural Science Foundation of China [Grant Number 51771117] and Collaborative Innovation Center for Advanced Ship and Deep-sea Exploration (Shanghai Jiao Tong University). We are indebted to the Center for Advanced Electronic Materials and Devices (AEMD, Shanghai Jiao Tong University) for test supports.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, T., Ding, Y., Luo, Q. et al. The Effects of Sodium Tungstate on the Characteristics of Microarc Oxidation Coating on Ti6Al4V. J. of Materi Eng and Perform 27, 5489–5499 (2018). https://doi.org/10.1007/s11665-018-3613-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3613-2