Abstract

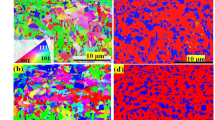

A medium carbon alloy steel is processed by austenizing at 900 °C for 30 min, then rapid quenching into a patented quenching liquid and holding at 170 °C for 5 min, finally isothermally holding at 250 °C for different times. The morphology and mechanical properties are performed by using optical microscopy and scanning electron microscopy. A multiphase microstructure characterized by a mixture of lenticular prior martensite (PM), fine needle bainitic ferrite and filmy retained austenite (RA) is obtained. It is found that the PM formed firstly upon quenching can accelerate the subsequent bainitic transformation and promote refinement of multiphase colonies. The results show that an optimum mechanical property of a 4000.9 MPa bending strength and a 2030 MPa tensile strength is achieved at 250 °C for 120 min, which is attributed to the multiphase microstructural characteristics and a high product of the volume fraction of RA and the carbon content of austenite.

Similar content being viewed by others

References

F.G. Caballero, S. Allain, J.D. Puerta-Velásquez, and C. Garcia-Mateo, Exploring Carbide-Free Bainitic Structures for Hot Dip Galvanizing Products, ISIJ Int., 2013, 53, p 1253-1259

D.T. Pierce, D.R. Coughlin, D.L. Williamson, K.D. Clarke, A.J. Clarke, J.G. Speer, and E. De Moor, Characterization of Transition Carbides in Quench and Partitioned Steel Microstructures by Mössbauer Spectroscopy and Complementary Techniques, Acta Mater., 2015, 90, p 417-430

Y. Chang, G.Z. Li, C.Y. Wang, X.D. Li, and H. Dong, Effect of Quenching and Partitioning with Hot Stamping on Martensite Transformation and Mechanical Properties of AHSS, J. Mater. Eng. Perform., 2015, 24, p 3194-3200

N. Fonstein, Candidates for Third-Generation Steels: Q&P Processed Steels. In Advanced High Strength Sheet Steels: Physical Metallurgy, Design, Processing, and Properties, 1st edn (Springer International Publishing, 2015), chapter 10: p 327-368

D.V. Edmonds, K. He, F.C. Rizzo, B.C. De Cooman, D.K. Matlock, and J.G. Speer, Quenching and Partitioning Martensite—A Novel Steel Heat Treatment, Mater. Sci. Eng. A, 2006, 438-440, p 25-34

H. Wu, C. Liu, Z. Zhao, Y. Zhao, S. Zhu, Y. Liu, and S. Bhole, Design of Air-cooled Bainitic Microalloyed Steel for a Heavy Truck Front Axle Beam, Mater. Des., 2006, 27, p 651-656

S. Samanta, S. Das, D. Chakrabarti, I. Samajdar, S.B. Singh, and A. Haldar, Development of Multiphase Microstructure with Bainite, Martensite, and Retained Austenite in a Co-Containing Steel Through Quenching and Partitioning (Q&P) Treatment, Metall. Mater. Trans. A, 2013, 44, p 5653-5664

M. Koyama, Z. Zhang, M.M. Wang, D. Ponge, D. Raabe, K. Tsuzaki, H. Noguchi, and C.C. Tasan, Bone-like Crack Resistance in Hierarchical Metastable Nanolaminate Steels, Science, 2017, 355, p 1055-1057

C. Yang, X.X. Cui, and C. Liu, Multiphase Matrix Structure of Unalloyed Austempered Ductile Iron, Mater. Sci. Technol., 2018, 34, p 261-267

F. Tariq and R.A. Baloch, One-Step Quenching and Partitioning Heat Treatment of Medium Carbon Low Alloy Steel, J. Mater. Eng. Perform., 2014, 23, p 1726-1739

C. Liu, C. Yang, L.M. Yuan, and D.O. Northwood, Role of Pre-formed Martensite on Transformation of Austempered Ductile Iron, Mater. Sci. Technol., 2017, 33, p 1819-1828

H. Amel-Farzad, H.R. Faridi, F. Rajabpour, A. Abolhasani, S. Kazemi, and Y. Khaledzadeh, Developing Very Hard Nanostructured Bainitic Steel, Mater. Sci. Eng. A, 2013, 559, p 68-73

R.M. Wu, W. Li, S. Zhou, Y. Zhong, L. Wang, and X.J. Jin, Effect of Retained Austenite on the Fracture Toughness of Quenching and Partitioning (Q&P)-treated Sheet Steels, Metall. Mater. Trans. A, 2014, 45, p 1892-1902

Y. Toji, H. Matsuda, and D. Raabe, Effect of Si on the Acceleration of Bainite Transformation by Pre-existing Martensite, Acta Mater., 2016, 116, p 250-262

C.E. Ericsson, M.S. Bhat, E.R. Parker, and V.F. Zackay, Isothermal Studies of Bainitic and Martensitic Transformations in Some Low Alloy Steels, Metall. Trans. A, 1976, 7, p 1800-1803

H. Kawata, K. Hayashi, N. Sugiura, N. Yoshinaga, and M. Takahashi, Effect of Martensite in Initial Structure on Bainite Transformation, Mater. Sci. Forum, 2010, 638, p 3307-3312

W. Gong, Y. Tomota, S. Harjo, Y.H. Su, and K. Aizawa, Effect of Prior Martensite on Bainite Transformation in Nanobainite Steel, Acta Mater., 2015, 85, p 243-249

A. Navarro-López, J. Sietsma, and M.J. Santofimia, Effect of Prior Athermal Martensite on the Isothermal Transformation Kinetics Below Ms in a Low-C High-Si Steel, Metall. Mater. Trans. A, 2016, 47, p 1028-1039

H. Santos, A. Duarte, and J. Seabra, Austempered Ductile Iron with Tempered Martensite, lnt. J. Cast Met. Res., 2002, 15, p 117-124

C.J. Martis, S.K. Putatunda, and J. Boileau, Processing of New High Strength High Toughness Steel with Duplex Microstructure (Ferrite + Austenite), Mater. Des., 2013, 46, p 168-174

Y. Huang, X.L. Zhang, W.N. Liu, X.M. Wang, and J.K. Han, Microstructure and Mechanical Properties of NANOBAIN Steel, J. Iron. Steel Res. Int., 2016, 23, p 253-260

M.N. Yoozbashi and S. Yazdani, Mechanical Properties of Nanostructured, Low Temperature Bainitic Steel Designed Using a Thermodynamic Model, Mater. Sci. Eng. A, 2010, 527, p 3200-3205

P. Luo, G. Gao, H. Zhang, Z. Tan, R.D.K. Misra, and B.Z. Bai, On Structure-property Relationship in Nanostructured Bainitic Steel Subjected to the quenching and partitioning process, Mater. Sci. Eng. A, 2016, 661, p 1-8

H. Wu, Y. Jiang, S.S. You, Y. Han, and Y.X. Liu, Study on TRIP Effect of Retained Austenite in Super-bainite Microstructure, J. Mech. Eng., 2014, 50, p 69-75 (in Chinese)

Y. Han, H. Wu, C. Liu, and Y.X. Liu, Medium Carbon Super-Bainitic Steel After Isothermal Transformation. J. Mater. Eng. Perform. 2014, 23, p 4230-4236

X. Zhang, G. Xu, X. Wang, D. Embury, O. Bouaziz, O. Bouaziz, G.R. Purdy, and H.S. Zurob, Mechanical Behavior of Carbide-free Medium Carbon Bainitic Steels, Metall. Mater. Trans. A, 2014, 45, p 1352-1361

D.P. Koistinen and R.E. Marburger, A General Equation Prescribing the Extent of the Austenite-Martensite Transformation in Pure Iron-carbon Alloys and Plain Carbon Steels, Acta Metall., 1959, 7, p 59-60

J. Mallia, M. Grech, and R.E. Smallman, Effect of Silicon Content on Transformation Kinetics of Austempered Ductile Iron, Mater. Sci. Technol., 1998, 14, p 452-460

C. Yang, X.X. Cui, Z.B. Zhao, G. Hua, and C. Liu, Role of Bulky Retained Austenite in Austempered Ductile Iron, Adv. Mater. Res., 2016, 1142, p 19-22

S.M.C. van Bohemen, Bainite and Martensite Start Temperature Calculated with Exponential Carbon Dependence, Mater. Sci. Technol., 2012, 28, p 487-495

Y.F. Shen, L.N. Qiu, X. Sun, L. Zuo, P.K. Liaw, and D. Raabe, Effects of Retained Austenite Volume Fraction, Morphology, and Carbon Content on Strength and Ductility of Nanostructured TRIP-assisted Steels, Mater. Sci. Eng. A, 2015, 636, p 551-564

S.K. Putatunda and P.K. Gadicherla, Effect of Austempering Time on Mechanical Properties of a Low Manganese Austempered Ductile Iron, J. Mater. Eng. Perform., 2000, 9, p 193-203

W.S. Li, H.Y. Gao, Z.Y. Li, H. Nakashima, S. Hata, and W.H. Tian, Effect of Lower Bainite/Martensite/Retained Austenite Triplex Microstructure on the Mechanical Properties of a Low-carbon Steel with Quenching and Partitioning Process, Int. J. Min. Met. Mater., 2016, 23, p 303

K. Abbaszadeh, H. Saghafian, and S. Kheirandish, Effect of Bainite Morphology on Mechanical Properties of the Mixed Bainite-martensite Microstructure in D6AC Steel, J. Mater. Sci. Technol., 2012, 28, p 336-342

K.K. Wang, Z.L. Tan, G.H. Gao, and X.L. Gui, R.DK. Misra and B.Z. Bai, Ultrahigh Strength-toughness Combination in Bainitic Rail Steel: The Determining Role of Austenite Stability during Tempering, Mater. Sci. Eng. A, 2016, 662, p 162-168

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Cui, X. & Yang, C. Multiphase Microstructure in a Metastability-Assisted Medium Carbon Alloy Steel. J. of Materi Eng and Perform 27, 3239–3247 (2018). https://doi.org/10.1007/s11665-018-3378-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3378-7