Abstract

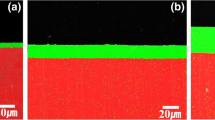

Features of transient liquid phase (TLP) bondability of high-volume fraction (70 vol.%) SiC particle-reinforced A356 composite for popular Cu interlayer were investigated. Although Cu foil was melted, molten Cu was completely expulsed, indicating that the numerous SiC particles significantly deteriorated wettability not only at particle/braze metal (P/M) interface, but also at the matrix/braze metal (M/M) interface. For the reason of poor wettability at P/M interface, a model showing there is a “window period” for actual wetting reaction (allowing liquid phase to be in contact with surficial SiC particles) much shorter than nominal isothermal solidification time during TLP bonding of the composite containing sintered ceramic preform was proposed. For the poor wettability at M/M interface, both size effect of too small matrix unit (2 ~ 20 μm) and restraint effect of the rigid porous ceramic preform on suppressing oxide film crack on the small matrix unit surface were proposed. Thus, chemical route to disrupt oxide film on the small matrix unit surface should be preferred in braze composition design. For example, Al-27Cu-5Si-2Mg-1Ti braze was developed by co-addition of Mg and Ti to improve wettability and to in situ reinforce bond seam, respectively; Ti also could remedy Mg loss for improving wettability.

Similar content being viewed by others

References

M.B.D. Ellis, Joining of Aluminum Base Metal Matrix Composites, Int. Mater. Rev., 1996, 41(2), p 41–58

A. Ureña, M.D. Escalera, and L. Gil, Influence of Interface Reactions on Fracture Mechanisms in TIG Arc-Welded Aluminium Matrix Composites, Compos. Sci. Technol., 2000, 60(4), p 613–622

D. Storjohann, O.M. Barabash, S.S. Babu, S.A. David, P.S. Sklad, and E.E. Bloom, Fusion and Friction Stir Welding of Aluminum-Metal-Matrix Composites, Metall. Mater. Trans. A, 2005, 36(11), p 3237–3247

Z.Y. Ma, A.H. Feng, B.L. Xiao, J.Z. Fan, and L.K. Shi, Microstructural Evolution and Performance of Friction Stir Welded Aluminum Matrix Composite Reinforced by SiC Particles, Mater. Sci. Forum, 2007, 539–543, p 3814–3819

D.S. Duvall, W.A. Owczarski, and D.F. Paulonis, TLP Bonding: A New Method for Joining Heat Resistant Alloys, Weld J., 1974, 53(4), p 203–214

W.F. Gale and D.A. Butts, Transient Liquid Phase Bonding, Sci. Technol. Weld. Join., 2004, 9(4), p 283–300

G.O. Cook, III, and C.D. Sorensen, Overview of Transient Liquid Phase and Partial Transient Liquid Phase Bonding, J. Mater. Sci., 2011, 46(16), p 5305–5323

Y. Zhou, W.F. Gale, and T.H. North, Modelling of Transient Liquid Phase Bonding Transient Liquid Phase Bonding, Int. Mater. Rev., 1995, 40(5), p 181–196

I. Tuah-poku, M. Dollar, and T.B. Massalski, A Study of the Transient Liquid Phase Bonding Process Applied to a Ag/Cu/Ag Sandwich Joint, Metall. Trans. A, 1988, 19A(3), p 675–686

O.S. Salih, H. Ou, W. Sun, and D.G. McCartney, A Review of Friction Stir Welding of Aluminium Matrix Composites, Mater. Des., 2015, 86(5), p 61–71

T. Enjo, K. Ikeuchi, Y. Murakami, and N. Suzuki, Diffusion Bonding of Al-Mg-Si Series of 6063 Alloy Reinforced with Alumina Short Fibers, Trans. JWRI, 1987, 16(2), p 285–292

R. Klehn and T.W. Eagar, Joining of 6061 Aluminum Matrix-Ceramic Particle Reinforced Composite, WRC Bull., 1993, 385, p 1–26

Z. Li, Y. Zhou, and T.H. North, Counteraction of Particulate Segregation During Transient Liquid Phase Bonding of Aluminum Based MMC Materials, J. Mater. Sci., 1995, 30(12), p 1075–1082

Z. Li, W. Fearis, and T.H. North, Particulate Segregation and Mechanical Properties in Transient Liquid Phase Bonded Metal Matrix Composite Material, Mater. Sci. Technol., 1995, 11(4), p 363–369

Y. Zhai, T.H. North, and J. Serrato-Rodrigues, Transient Liquid Phase Bonding of Alumina and Metal Matrix Composite Base Materials, J. Mater. Sci., 1997, 32(6), p 1393–1397

Y. Zhai and T.H. North, Counteracting Particulate Segregation During Transient Liquid Phase Bonding of MMC-MMC and Al2O3-MMC Joints, J. Mater. Sci., 1997, 32(21), p 5571–5575

A.A. Shirzadi and E.R. Wallach, New Approaches for Transient Liquid Phase Diffusion Bonding of Aluminium Based Metal Matrix Composites, Mater. Sci. Technol., 1997, 13(2), p 135–142

M. Yarahmadi, M. Shamanian, H.R. Salimi Jazi, and H.R. Hoshyarmanesh, Transient Liquid Phase Diffusion Bonding of Al/Al2O3 Nanostructured Metal Matrix Composites, Sci. Technol. Weld. Join., 2014, 19(7), p 603–608

J. Maity, T.K. Pal, and R. Maiti, Microstructural Characterization of TLPD Bonded 6061-SiCp Composite, J. Mater. Eng. Perform., 2008, 17(5), p 746–754

P. Roy, T.K. Pal, and J. Maity, Transient Liquid Phase Diffusion Bonding of 6061Al-15 wt.% SiCp Composite Using Mixed Cu-Ag Powder Interlayer, J. Mater. Eng. Perform., 2016, 25(8), p 3518–3530

H. Nami, A. Halvaee, and H. Adgi, Transient Liquid Phase Diffusion Bonding of Al/Mg2Si Metal Matrix Composite, Mater. Des., 2011, 32(7), p 3957–3965

S.S. Sayyedain, H.R. Salimijazi, M.R. Toroghinejad, and F. Karimzadeh, Microstructure and Mechanical Properties of Transient Liquid Phase Bonding of Al2Op3/Al Nanocomposite Using Copper Interlayer, Mater. Des., 2014, 53, p 275–282

A. Suzumura and Y.J. Xing, Diffusion Brazing of Short Al2O3 Fiber-Reinforced Aluminum Composite, Mater. Trans. JIM, 1996, 37(5), p 1109–1115

J.R. Askew, J.F. Wilde, and T.I. Khan, Transient Liquid Phase Bonding of 2124 Aluminum Metal Matrix Composite, Mater. Sci. Technol., 1998, 14(9–10), p 920–924

K.O. Cooke, T.I. Khan, and G.D. Oliver, Transient Liquid Phase Diffusion Bonding Al-6061 Using Nano-dispersed Ni Coatings, Mater. Des., 2012, 33, p 469–475

K.O. Cooke, T.I. Khan, and G.D. Oliver, Nanostructure Particle Reinforced Transient Liquid Phase Diffusion Bonding: A Comparative Study, Metall. Mater. Trans., 2011, 42(8), p 2271–2277

K.O. Cooke, T.I. Khan, and G.D. Oliver, Effect of Ni-Al2O3 Nanocomposite Coating Thickness on Transient Liquid Phase Bonding of Al 6061 MMC, Sci. Technol. Weld. J., 2012, 17(1), p 22–31

J. Yan, Z. Xu, G. Wu, and S. Yang, Interface Structure and Mechanical Performance of TLP Bonded Joints of Al2O3p/6061Al Composites Using Cu/Ni Composite Interlayers, Scr. Mater., 2004, 51(2), p 147–150

W.H. Liu, D.Q. Sun, S.S. Jia, and X.M. Qiu, Transient Liquid Phase Bonding of Aluminum Metal Matrix Composite with Al-Cu Interlayer, Trans. China Weld. Inst., 2003, 24(5), p 13–16

M. Naka and K.M. Hafez, Applying of Ultrasonic Waves on Brazing of Alumina to Copper Using Zn-Al Filler Alloy, J. Mater. Sci., 2003, 38(16), p 3491–3494

M. Naka, M. Maeda, and I. Okamoto, Ultrasonic Brazing of Alumina to Copper Using Zn-Al Filler, Trans. JWRI, 1989, 18(1), p 75–79

M. Naka and M. Maeda, Ultrasonic Brazing of Alumina to Copper Using Zn-Al-Cu Fillers, Trans. JWRI, 1991, 20(1), p 91–96

J.C. Yan, H.B. Xu, Z.W. Xu, B.Y. Zhang, and S.Q. Yang, Interface Structure Changes During Vibration Liquid Phase Bonding of SiCp/A356 Composites in Air, Compos. Part A Appl. Sci. Manuf., 2006, 37(9), p 1458–1463

J.C. Yan, H.B. Xu, L. Shi, X.L. Wang, and S.Q. Yang, Vibration Assisted Brazing of SiCp/A356 Composites: Microstructure and Mechanical Behaviour, Sci. Technol. Weld. Join., 2008, 13(8), p 760–764

Y. Zhang, J.C. Yan, and Q. Wu, Ultrasonic Brazing of High Fraction Volume of SiC Particulate Reinforced Aluminium Matrix Composites, Mater. Sci. Technol., 2009, 25(3), p 379–382

J.C. Yan, W.W. Zhao, H.B. Xu, D. Li, and Z.W. Xu, Ultrasonic Brazing of Aluminum Alloy and Aluminum Matrix Composite, USD Patent No. USP3875C, 2009

J.C. Yan, Z.W. Xu, L. Shi, X. Ma, and S.Q. Yang, Ultrasonic Assisted Fabrication of Particle Reinforced Bonds Joining Aluminum Metal Matrix Composites, Mater. Des., 2011, 32(1), p 343–347

Z.W. Xu, J.C. Yan, B.Y. Zhang, X.L. Kong, and S.Q. Yang, Behaviors of Oxide Film at the Ultrasonic Aided Interaction Interface of Zn-Al Alloy and Al2O3p/6061Al Composite in Air, Mater. Sci. Eng., 2006, 415(1–2), p 80–86

Z.W. Xu, J.C. Yan, G.H. Wu, X.L. Kong, and S.Q. Yang, Interface Structure of Ultrasonic Vibration Aided Interaction Between Zn-Al Alloy and Al2O3p/6061Al Composite, Compos. Sci. Technol., 2005, 65(13), p 1959–1963

Z. Xu, L. Ma, J. Yan, S. Yang, and S. Du, Wetting and Oxidation During Ultrasonic Soldering of an Alumina Reinforced Aluminum–Copper–Magnesium (2024 Al) Matrix Composite, Compos. Part A Appl. Sci. Manuf., 2012, 43(3), p 407–414

S. Weis, I. Hoyer, and B. Wielage, Joining of High-Strength Aluminum-Based Materials with Tin-Based Solders, Weld. J., 2008, 87(3), p 35–37

B. Wielage, I. Hoyer, and S. Weis, Soldering Aluminum Matrix Composites, Weld. J., 2007, 86(3), p 67–70

H.B. Xu, Q.X. Xing, Y.L. Zeng, Y. Luo, and C.H. Du, Semisolid Stirring Brazing of SiCp/A356 Composites with Zn27Al Filler Metal in Air, Sci. Technol. Weld. Join., 2011, 16(6), p 483–487

S.X. Lv, Z.S. Yu, Z.W. Xu, and J.C. Yan, Fluxless Pressure Soldering for SiCw/ 6061Al Composites, Trans. China Weld. Inst., 2001, 22(4), p 73–76

W. Guo, M. Hua, and J.K.L. Ho, Study on Liquid-Phase-Impact Diffusion Welding SiCp/ZL101, Compos. Sci. Technol., 2007, 67(67), p 1041–1046

A. Suzumura, Y.J. Xing, K. Takahashi, and T. Onzawa, Effects of Surface Polishing on the Wettability of Alumina Short Fiber Reinforced Al Matrix Composite, Prepr. Natl. Meet. J. W. S., 1993, 52, p 166–167

A. Suzumura, Y.J. Xing, and K. Takahashi, Behavior of Fibers in the Joint of Alumina Short Fiber Reinforced Al Matrix Composite, Prepr. Natl. Meet. J. W. S., 1993, 53, p 326–327

A. Suzumura and Y.J. Xing, Brazing of Alumina Short Fiber Reinforced Aluminum Composite, Prepr. Natl. Meet. J. W. S., 1994, 55, p 282–283

A. Suzumura, M. Matsumoto, and Y.J. Xing, Effects of Interlayer Behavior on the Braze-Ability of Alumina Short Fiber Reinforced Al Composite, Prepr. Natl. Meet. J. W. S., 1996, 59, p 262–263

H. Kokawa, K. Mitsuzuka, and T. Kuwana, Brazing of SiC Particle Reinforced Aluminum Composite, Prepr. Natl. Meet. J. W. S., 1993, 52, p 176–177

X.P. Zhang, G.F. Quan, and W. Wei, Preliminary Investigation on Joining Performance of SiCp-Reinforced Aluminium Metal Matrix Composite (Al/SiCp-MMC) by Vacuum Brazing, Compos. Part A Appl. Sci. Manuf., 1999, 30(6), p 823–827

J.S. Zou, Z. Chen, R.Q. Xu, and Q.Z. Zhao, Vacuum Brazing of SiCp/LY12 Metal Matrix Composites, Chin. J. Nonferrous Met., 2004, 14(1), p 74–78

J.S. Zou, R.Q. Xu, Q.Z. Zhao, and Y.S. Han, Wettability of Aluminum Base Filler Metals on SiC and SiCp/6061 Composites, Mater. Dev. Appl., 2003, 18(4), p 5–8

J.S. Zou, R.Q. Xu, Q.Z. Zhao, and Z. Chen, Study on Vacuum Induction Brazing of SiCp/LY12 Composite Using Al-Cu-Si-Mg Filler Metal, China Weld., 2003, 12(2), p 107–111

J.B. Lu, Y.C. Mu, X.W. Luo, and J. Niu, A New Method for Soldering Particle-Reinforced Aluminum Metal Matrix Composites, Mater. Sci. Eng. B, 2012, 177(20), p 1759–1763

L. Liu, M.L. Zhu, L.X. Pan, and L. Wu, Studying of Micro-bonding in Diffusion Welding Joint for Composite, Mater. Sci. Eng. A, 2001, 315(1–2), p 103–107

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Keck, The Fabrication of Metal Matrix Composites by a Pressureless Infiltration Technique, J. Mater. Sci., 1991, 26(2), p 447–454

D.J. Lloyd, Particle Reinforced Aluminium and Magnesium Matrix Composites, Int. Mater. Rev., 1994, 39(1), p 1–23

K. Kotani, J.P. Jung, K. Ikeuchi, and F. Matsuda, Effects of Interfacial Phases on Bond Strength of Diffusion-Bonded Joints of Al-X Binary Alloys (X = Mg, Si, Mn, Zn, Cu)—Diffusion-Bonding Mechanism of Al Alloys by Transmission Electron Microscopy (Report 6), Q. J. Jpn. Weld. Soc., 2000, 18(4), p 580–589

F.J. Cheng, J.F. Yao, Z.W. Yang, Y. Wang, and B. Xiao, Structure and Composition of Oxide Film on 5083 Alloy at Brazing Temperature, Mater. Sci. Technol., 2015, 31(11), p 1282–1287

J.T. Niu, X.W. Luo, H. Tian, and J. Brnic, Vacuum Brazing of Aluminium Metal Matrix Composite (55 vol.% SiCp/A356) Using Aluminium-Based Filler Alloy, Mater. Sci. Eng. B, 2012, 177(19), p 1707–1711

J. Li and K.H. Wang, Vacuum Brazing of Aluminum Metal Matrix Composites (70 vol.% SiCp/Al) Using Al-15Cu-8.5Si-4Ni-1.5Mg Filler Metal, Appl. Mech. Mater., 2014, 633–634, p 760–763

G.F. Zhang, J.X. Zhang, Y. Pei, S.Y. Li, and D.L. Chai, Joining of Al2O3p/Al Composites by Transient Liquid Phase (TLP) Bonding and a Novel Process of Active-Transient Liquid Phase (A-TLP) Bonding, Mater. Sci. Eng. A, 2008, 488(1), p 146–156

G.F. Zhang, X.J. Liao, B. Chen, and J.X. Zhang, Approach to In-Situ Producing Reinforcing Phase Within an Active-Transient Liquid Phase Bond Seam for Aluminum Matrix Composite, Metall. Mater. Trans. A, 2015, 46(6), p 2568–2578

G.F. Zhang, W. Su, and A. Suzumura, Active-Transient Liquid Phase (A-TLP) Bonding of Pure Aluminum Matrix Composite Reinforced with Short Alumina Fiber Using Al-12Si-xTi Foils as Active Interlayer, Metall. Mater. Trans. B, 2016, 47(3), p 1–14

G.F. Zhang, W. Su, J.X. Zhang, and A. Suzumura, Wetting Behavior of a Novel Al-Si-Ti Active Brazing Filler Metal Foil on Aluminum Matrix Composite, J. Mater. Eng. Perform., 2013, 22(7), p 1982–1994

G.F. Zhang, B. Chen, M.Z. Jin, and J.X. Zhang, Active-Transient Liquid Phase (A-TLP) Bonding of High Volume Fraction SiC Particle Reinforced A356 Matrix Composite, Mater. Trans., 2015, 56(2), p 212–217

W.P. Weng and T.H. Chuang, Brazing of Aluminum Matrix Composite with Sn10Ag4Ti Active Filler Metal, Mater. Manuf. Process., 1997, 12(6), p 1107–1132

P. Wang, D.X. Xu, D.F. Cheng, Q. Li, and J.T. Niu, Active Brazing Filler Metal on SiC Particle Reinforced Aluminium Matrix Composites, Sci. Technol. Weld. Join., 2015, 20(5), p 361–370

P. Wang, Z. Gao, and J.T. Niu, Micro–nano Filler Metal Foil on Vacuum Brazing of SiCp/Al Composites, Appl. Phys. A, 2016, 122, p 592

S.J. Chen, M.Q. Wei, and P.F. Zhao, Study on Microstructure and Property of Aluminum Matrix Composites SiCP/Al6063 Vacuum Brazing Joint with Different Holding Time, Trans. China Weld. Inst., 2015, 36(10), p 87–90

J.H. Huang, Y.L. Dong, and Y. Wan, Investigation on Reactive Diffusion Bonding of SiCP/6063 MMC by Using Mixed Powders as Interlayers, J. Mater. Process. Technol., 2007, 190(190), p 312–316

G.F. Zhang, J. Cai, B.Q. Chen, and T.T. Xu, Availability of In-Situ Reinforced Active-Transient Liquid Phase Bond with Good Wettability for 70 vol.% SiCp/A356 Composite Using Al-Mg-Ga-Ti Interlayer, Mater. Des., 2016, 110, p 653–662

J.T. Niemann and G.W. Wille, Fluxless Diffusion Brazing of Aluminum Castings, Weld. J., 1978, 52(10), p 285–291

T. Osawa, Changes in the Interface Structure and Strength of Diffusion Brazed Joints of Al-Si System Alloy Castings, Weld. J., 1995, 74(6), p 206–212

R. Asthana, Review: Reinforced Cast Metals, Part II, Evolution of the Interface, J. Mater. Sci., 1998, 33(8), p 1959–1980

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Particulate Reinforced Metal Matrix Composites—A Review, J. Mater. Sci., 1991, 26(5), p 1137–1156

B.C. Pai, G. Ramani, R.M. Pillai, and K.G. Satyanarayana, Review: Role of Magnesium in Cast Aluminium Alloy Matrix Composites, J. Mater. Sci., 1995, 30(8), p 1903–1911

T.S. Srivatsan, I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Processing Techniques for Particulate Reinforced Metal Aluminium Matrix Composites, J. Mater. Sci., 1991, 26(22), p 5965–5978

T.P.D. Rajan, R.M. Pillai, and B.C. Pai, Review: Reinforcement Coatings and Interfaces in Aluminium Metal Matrix Composites, J. Mater. Sci., 1998, 33(14), p 3491–3503

K. Sukumaran, S.G.K. Pillai, R.M. Pillai, V.S. Kelukutty, B.C. Pai, K.G. Satyanarayana, and K.K. Ravikumar, The Effects of Magnesium Additions on the Structure and Properties of Al-7Si-10SiCp Composites, J. Mater. Sci., 1995, 30(6), p 1469–1472

J. Hashim, L. Looney, and M.S.J. Hashmi, The Enhancement of Wettability of SiC Particles in Cast Aluminum Matrix Composite, J. Mater. Process. Technol., 2001, 119(1), p 329–335

M. Kobashi and T. Choh, The Wettability and the Reaction for SiC Particle/Al Alloy System, J. Mater. Sci., 1993, 28(28), p 684–690

O. Beffort, S. Long, C. Cayron, J. Kuebler, and P.A. Buffat, Alloying Effects on Microstructure and Mechanical Properties of High Volume Fraction SiC-Particle Reinforced Al-MMCs Made by Squeeze Casting Infiltration, Compos. Sci. Technol., 2007, 67(3–4), p 737–745

Acknowledgments

The present research was supported by the National Science Foundation of China (Nos. 51275390 and 50875199).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Wei, Z., Chen, B. et al. Abnormal Transient Liquid Phase Bondability of High-Volume Fraction SiC Particle-Reinforced A356 Composite for Cu Interlayer and the Interlayer Improvement Routes. J. of Materi Eng and Perform 26, 5921–5937 (2017). https://doi.org/10.1007/s11665-017-3070-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3070-3