Abstract

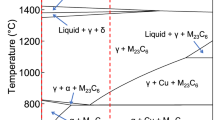

The present work discusses the development of very hard Cr and Cr-carbide coating by roll bonding of Cr powder on a mild steel followed by annealing at 800, 1000, 1100 and 1200 °C with and without the presence of graphite powder packing in argon environment. In addition, the effect of a roll skin pass of 5% prior to the application of coating was studied. The presence of graphite allows diffusion of both carbon and Cr in the mild steel substrate, leading to the formation of Cr-carbide on the outer surface, making the surface very hard (VHN ~ 1800). Depending on the annealing temperature and processing condition, diffusion layer thickness of Cr is found to be in the range of 10-250 μm with Cr content of 12.5-15 wt.% across the diffusion layer. Excellent stable passivity of the coated surface is observed in 0.2 N H2SO4, which is comparable to a highly passivating 304 stainless steel, and very low corrosion rate of the coating is observed as compared to the substrate mild steel.

Similar content being viewed by others

References

C.A.C. Sequeira, A.M.G. Pacheco, and C.M.G.S. Nunes, Formation of Diffusion Coatings on Iron and Steel: 3 Aluminium, Chromium and Zinc Coatings, Surf. Eng., 1988, 4(1), p 65–81

V.E. Carter, Metallic Coatings for Corrosion Control: Corrosion Control Series, Elsevier, Amsterdam, 2013

A.R. Castle and D.R. Gabe, Chromium Diffusion Coatings, Int. Mater. Rev., 1999, 44(2), p 37–58

P.S. Sidky and M.G. Hocking, Review of Inorganic Coatings and Coating Processes for Reducing Wear and Corrosion, Br. Corros. J., 1999, 34, p 171–183

F.A.P. Fernandes, S.C. Heck, C.A. Picon, G.E. Totten, and L.C. Casteletti, Wear and Corrosion Resistance of Pack Chromised Carbon Steel, Surf. Eng., 2012, 28(5), p 313–317

P. Jayaweera, D.M. Lowe, A. Sanjurjo, K.H. Lau, and L. Jiang, Corrosion-Resistant Metallic Coatings on Low Carbon Steel, Surf. Coat. Technol., 1996, 86–87(6), p 522–525

A. Popoola, O.E. Olorunniwo, and O.O. Ige, Corrosion resistance through the application of anti-corrosion coatings, Developments in Corrosion Protection, M. Aliofkhazraei, Ed., Intech, Pretoria, 2014, p 241–270

N. Priyantha, P. Jayaweera, A. Sanjurjo, K. Lau, F. Lu, and K. Krist, Corrosion-Resistant Metallic Coatings for Applications in Highly Aggressive Environments, Surf. Coat. Technol., 2003, 163–164, p 31–36

D.S. Rickerby and R.A.B. McCall, Corrosion Protective Coating for a Metallic Article and a Method of Applying a Corrosion Protective Coating to a Metallic Article. US patent, 6,565,931, 20 May 2003

S. Jahanmir, E.P. Abrahamson, and N.P. Suh, Sliding Wear Resistance of Metallic Coated Surfaces, Wear, 1976, 40(1), p 75–84

M.S. Priyan and P. Hariharan, Wear and Corrosion Resistance of Fe Based Coatings by HVOF Sprayed on Gray Cast-Iron for Automotive Application, Tribol. Ind., 2014, 36(4), p 394–405

W. Hanni and H.E. Hintermann, Chemical Vapour Deposition of Chromium, Solid Films, 1977, 40, p 107–114

K. Choy, Chemical Vapour Deposition of Coatings, Prog. Mater Sci., 2003, 48(2), p 57–170

H.O. Pierson, Handbook of Chemical Vapor Deposition: Principles, Technology and Applications, 2nd ed., William Andrew, London, 1999

J.L. Mazzochi, Chrome Plating Process. US patent, 5,401,379, 28 March 1995

M. Schlesinger and M. Paunovic, Ed., Modern Electroplating, Wiley, New York, 2011

M.H.A. Malek, N.H. Saad, S.K. Abas, N.N. Roselina, and N.M. Shah, Performance and Microstructure Analysis of 99.5% Aluminium Coating by Thermal Arc Spray Technique, Procedia Eng., 2013, 68, p 558–565

A.R. Marder, The Metallurgy of Zinc-Coated Steel, Prog. Mater Sci., 2000, 45(3), p 191–271

B. Tolaminejad and H. Arabi, A sTudy of Roll-Bonding MS90 Alloy to Steel Utilizing Chromized Interlayer, Iran. J. Sci. Technol. Trans. B Eng., 2008, 32(6), p 631–640

R.C. Agarwala and V. Agarwala, Electroless Alloy/Composite Coatings: A Review, Sadhana, 2003, 28(3), p 475–493

I.A. Menzies and D. Mortimer, Observatiońs on the Chromizing of Iron and Plain Carbon Steels, Corros. Sci., 1965, 5(8), p 539–558

I.A. Menzies and D. Mortimer, The Oxidation of Chromium Diffusion Coatings on Iron: Chromium Volatility and Experimental Techniques, Corros. Sci., 1966, 6, p 517–539

A.R. Castle and D.R. Gabe, Structural Characteristics of M23C6 Formed in Chromised Coatings on 11% Cr Steels, Mater. Sci. Technol., 2000, 16(9), p 1057–1066

F.C. Kelley, Surface Alloyed Metal. US patent, 1,365,499, 11 January 1921

H.C.P. Weber, Process of Producing Metal Substances. US patent, 1,373,038, 29 March 1921

E.H. Mayer and R.M. Willison, Formation of Chromium Containing Coatings on Steel Strip. US patent, 3,312,546, 4 April 1967

C.A. Vessey, Chromium Alloy Coated Ferrous Metal Products. US patent, 3,834,880, 10 September 1974

S. Khara, S. Choudhary, S. Sangal, and K. Mondal, Corrosion Resistant Cr-Coating on Mild Steel by Powder Roll Bonding, Surf. Coat. Technol., 2016, 296, p 203–210

I.N. Kidin, G.V. Shcherbedinskii, V.I. Andryushechkin, and V.A. Volkov, Effect of Preliminary Cold Plastic Deformation on Carbon Diffusion in Austenite, Met. Sci. Heat Treat., 1971, 13(12), p 1021–1023

N.H. Heo, H.D. Kim, K.T. Kim, J.K. Lee, and Y.C. Jung, Method for Preventing Carbon Steel from Intergranular Cracking. US patent, 201/00043926 A1, 2010

R.A. Al-Samarai, K.R.A. Haftirman, and Y. Al-Douri, The Influence of Roughness on the Wear and Friction Coefficient Under Dry and Lubricated Sliding, Int. J. Sci. Eng. Res., 2012, 2(3), p 2229–5518

J. Cheng, X. Liang, B. Xu, and Y. Wu, Formation and Properties of Fe-Based Amorphous/Nanocrystalline Alloy Coating Prepared by Wire Arc Spraying Process, J. Non-Cryst. Solids, 2009, 355, p 1673–1678

Y. Li, Y. Gao, B. Xiao, T. Min, Y. Yang, S. Ma, and D. Yi, The Electronic, Mechanical Properties and Theoretical Hardness of Chromium Carbides by First-Principles Calculations, J. Alloys Compd., 2011, 509(17), p 5242–5249

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, P., Khara, S., Shekhar, S. et al. Very Hard Corrosion-Resistant Roll-Bonded Cr Coating on Mild Steel in Presence of Graphite. J. of Materi Eng and Perform 26, 5885–5896 (2017). https://doi.org/10.1007/s11665-017-3050-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3050-7