Abstract

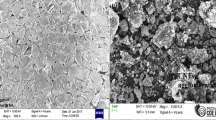

In this study, Ti-6Al-4V alloy was processed by pack carburizing to improve the cavitation erosion behavior. X-ray diffraction and scanning-electron microscopy (SEM) analysis showed that a uniform and crack-free ceramic coating formed on the surface of the treated samples. The coating layer comprised primary TiC and less oxide. Cavitation erosion experiment results indicated that the treated samples have the factor of 3.44 to 6.68 increase in cavitation erosion resistance (R e) as compared with the as-received sample. The ceramic coatings with high hardness and good metallurgical bonding were responsible for the enhanced cavitation erosion properties. When the coatings were treated at condition of high temperature and/or long time, the R e was enervated due to the thin oxide film formed at the outermost surface. Cavitation erosion mechanism for the coatings was characterized as brittle mode by SEM observation of the worn surfaces.

Similar content being viewed by others

References

M. Yamada, The State of the USA Titanium Industry in-1995, Mater. Sci. Eng. A, 1996, 213, p 8–15

D. Dube, M. Fiset, R. Laliberte, and R. Simoneau, Cavitation Resistance Improvement of IRECA Steel Via Laser Processing, Mater. Lett., 1996, 28, p 93–99

G. Straffelini and A. Molinari, Dry Sliding Wear of Ti-6Al-4V Alloy as Influenced by the Counterface and Sliding Conditions, Wear, 1999, 236(1–2), p 328–338

G. Straffelini, A. Andriani, B. Tesi, A. Molinari, and E. Galvanetto, Lubricated Rolling-Sliding Behaviour of Ion Nitrided and Untreated Ti-6Al-4V, Wear, 2004, 256(3–4), p 346–352

A. Neville and B.A.B. McDougall, Erosion- and Cavitation-Corrosion of Titanium and its Alloys, Wear, 2001, 250, p 726–735

M. Duraiselvam, R. Galun, V. Wesling, B.L. Mordike, R. Reiter, J. Oligmuller, and G. Buvanashekaran, Cavitation Erosion Resistance of Ti6Al4V Laser Alloyed with TiC-Reinforced Dual Phase Intermetallic Matrix Composites, Mater. Sci. Eng. A, 2007, 454–455, p 63–68

F.L. Palmieri, K.A. Watson, G. Morales, T. Williams, R. Hicks, C.J. Wohl, J.W. Hopkins, and J.W. Connell, Laser Ablative Surface Treatment for Enhanced Bonding of Ti-6Al-4V Alloy, ACS Appl. Mater. Interface, 2013, 5, p 1254–1261

H.C. Man, M. Bai, and F.T. Cheng, Laser Diffusion Nitriding of Ti-6Al-4V for Improving Hardness and Wear Resistance, Appl. Surf. Sci., 2011, 258, p 436–441

G. Cassar, S. Banfield, J.C. Avelar-Batista Wilson, J. Housden, A. Matthews, and A. Leyland, Impact Wear Resistance of Plasma Diffusion Treated and Duplex Treated/PVD-Coated Ti-6Al-4V Alloy, Surf. Coat. Technol., 2012, 206, p 2645–2654

B.S. Mann, V. Arya, and B.K. Pant, Impact Wear Resistance of Plasma Diffusion Treated and Duplex Treated/PVD-Coated Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2012, 21, p 849–853

H. Hiraga, T. Inoue, H. Shimura, and A. Matsunawa, Cavitation Erosion Mechanism of NiTi Coatings Made by Laser Plasma Hybrid Spraying, Wear, 1999, 231, p 272–278

H.C. Man, Z.D. Cui, T.M. Yue, and F.T. Cheng, Cavitation Erosion Behavior of Laser Gas Nitrided Ti and Ti6Al4V Alloy, Mater. Sci. Eng. A, 2003, 355, p 167–173

Z.D. Cui, H.C. Man, F.T. Cheng, and T.M. Yue, Microstructure and Wear Performance of Gradient Ti/TiN Metal Matrix Composite Coating Synthesized Using a Gas Nitriding Technology, Surf. Coat. Technol., 2003, 162, p 147–153

J. Kaspar, J. Bretschneider, S. Jacob, S. Bonß, B. Winderlich, and B. Brenner, Microstructure, Hardness and Cavitation Erosion Behaviour of Ti-6Al-4V Laser Nitrided Under Different Gas Atmospheres, Surf. Eng., 2007, 23, p 99–106

F. Fariaut, C. Boulmer-Leborgne, E. Le Menn, T. Sauvage, C. Andreazza-Vignolle, P. Andreazza, and C. Langlade, Excimer Laser Induced Plasma for Aluminum Alloys Surface Carburizing, Appl. Surf. Sci., 2002, 186, p 105–110

F. Çavuşlu and M. Usta, Kinetics and Mechanical Study of Plasma Electrolytic Carburizing for PURE IRON, Appl. Surf. Sci., 2011, 257, p 4014–4020

A.F. Saleh, J.H. Abboud, and K.Y. Benyounis, Surface Carburizing of Ti-6Al-4V Alloy by Laser Melting, Opt. Laser Eng., 2010, 48, p 257–267

T.I. Wu and J.K. Wu, Effects of Temperature and Current Density on the Surface Hardness and Tribological Properties of Ti-6Al-4V Alloy by Molten Salt Carburization, Surf. Coat. Technol., 1997, 90, p 258–267

C.J. Liao, Y.H. He, J.S. Yang, B. Nan, and X.L. Liu, Effect of Carburization on Electrochemical Corrosion Behaviours of TiAl Alloy, Mater. Sci. Eng. B, 2013, 178, p 449–456

K. Matsuura and M. Kudoh, Surface Modification of Titanium by a Diffusional Carbo-nitriding Method, Acta Mater., 2002, 50, p 2693–2700

T.S. Kim, Y.G. Park, and M.Y. Wey, Characterization of Ti-6Al-4V Alloy Modified by Plasma Carburizing Process, Mater. Sci. Eng. A, 2003, 361, p 275–280

Y.G. Park, M.Y. Wey, and S.I. Hong, Enhanced Wear and Fatigue Properties of Ti-6Al-4V Alloy Modified by Plasma Carburizing/CrN Coating, J. Mater. Sci., 2007, 18, p 925–931

S.A. Tsipas, M.R. Vázquez-Alcázar, E.M. Ruiz Navas, and E. Gordo, Boride Coatings Obtained by Pack Cementation Deposited on Powder Metallurgy and Wrought Ti and Ti-6Al-4V, Surf. Coat. Technol., 2010, 205, p 2340–2347

M. Shafiee Afarani, S. Khorshahian, and M. Sharifitabar, Boride Coatings Obtained by Pack Cementation Deposited on Powder Metallurgy and Wrought Ti and Ti-6Al-4V, Surf. Coat. Technol., 2013, 219, p 94–100

ASTM G32-98, Standard Test Method for Cavitation Erosion Using Vibratory Apparatus, vol. 03.02, 1998, p 115

M.X. Nie, Cavitation Prevention with Roughened Surface, J. Hydraul. Eng. ASCE., 2001, 127, p 878–880

D. Eylon, S. Fujishiro, P.J. Postans, and F.H. Froes, Titanium Technology, The Titanium Development Association Press, Dayton, 1985, p 87

R. Chatterjee-Fisher and T.S. Sundarshan, Boriding and Diffusion Metallizing, Marcel Dekker Inc. Press, New York, 1989, p 567–609

K.T. Rie and E. Broszeit, Plasma Diffusion Treatment and Duplex Treatment: Recent Development and New Applications, Surf. Coat. Technol., 1995, 76–77, p 425–436

M. Salehi and S.R. Hosseini, Structural Characterization of Novel Ti-Cu Intermetallic Coatings, Surf. Eng., 1996, 12, p 221–228

S.R. Hosseini and A. Ahmadi, Evaluation of the Effects of Plasma Nitriding Temperature and Time on the Characterisation of Ti 6Al 4V Alloy, Vacuum, 2013, 87, p 30–39

S. Farè, N. Lecis, M. Vedani, A. Silipigni, and P. Favoino, Properties of Nitrided Layers Formed During Plasma Nitriding of Commercially Pure Ti and Ti-6Al-4V Alloy, Surf. Coat. Technol., 2012, 206, p 2287–2292

F.C. Wagner, E.J. Bucur, and M.A. Steinberg, The Rate of Diffusion of Carbon in Alpha and Beta Titanium, Metall. Trans. ASM, 1956, 48, p 742–761

C.T. Kowk, F.T. Cheng, and H.C. Man, Laser Surface Modification of UNS S31603 Stainless Steel. Part II: Cavitation Erosion Characteristics, Mater. Sci. Eng. A, 2000, 290, p 74–88

H. Mochizuki, M. Yokota, and S. Hattori, Effects of Materials and Solution Temperatures on Cavitation Erosion of Pure Titanium and Titanium Alloy in Seawater, Wear, 2007, 262, p 522–528

T. Okada, Y. Iwai, and K. Azazu, A Study of Cavitation Bubble Collapse Pressures and Erosion. Part 1: A Method for Measurement of Collapse Pressures. Part 2: Estimate of Erosion from the Distribution of Bubble Collapse Pressures, Wear, 1989, 133, p 219–242

H.S. Sidhu, B.S. Sidhu, and S. Prakash, Solid Particle Erosion of HVOF Sprayed NiCr and Stellite-6 Coatings, Surf. Coat. Technol., 2007, 202, p 232–238

Acknowledgments

The authors would like to acknowledge the financial support from Tianjin University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Cui, Z., Li, Z. et al. Microstructure and Cavitation Erosion Properties of Ceramic Coatings Fabricated on Ti-6Al-4V Alloy by Pack Carburizing. J. of Materi Eng and Perform 23, 2772–2779 (2014). https://doi.org/10.1007/s11665-014-1030-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1030-8